A kind of preparation method of molecular sieve and its application and utilization method of waste water

A technology for molecular sieves and waste water, applied in molecular sieves and alkali exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., can solve problems such as high production costs, obstacles to industrial scale-up, and serious energy consumption in waste water treatment , to achieve the effect of improving anti-aging performance, increasing crystallinity and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

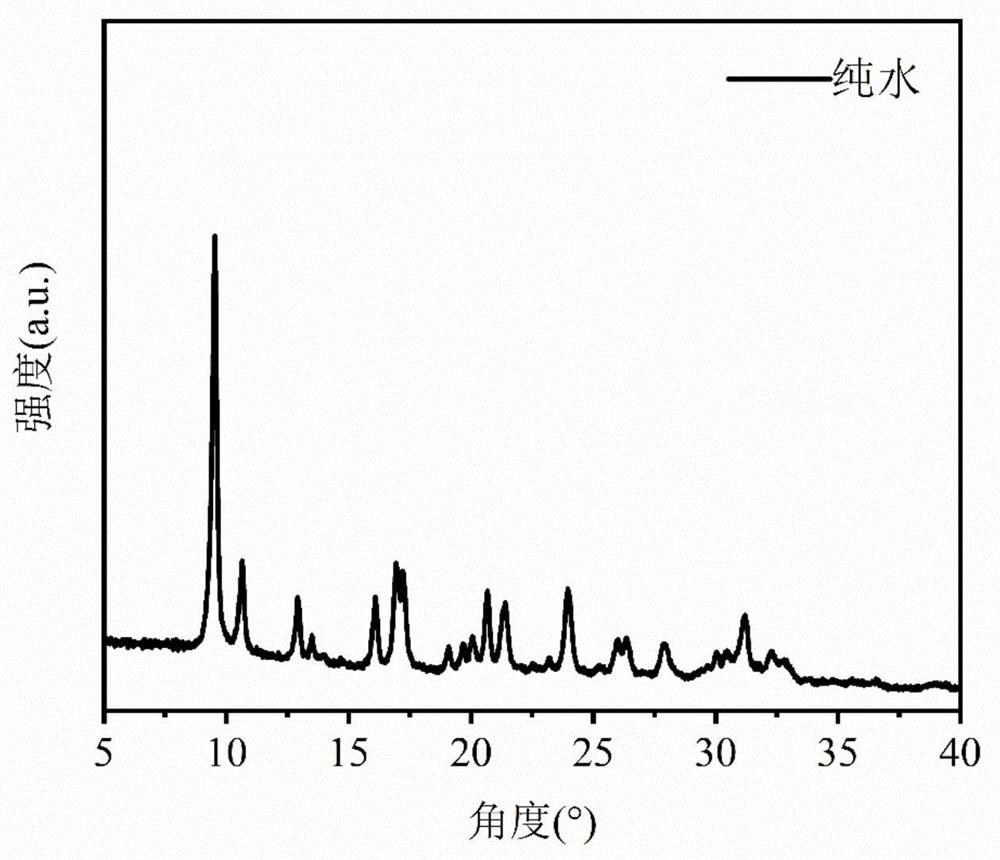

[0030] An embodiment of the present invention enhances a method of preparing a molecular sieve, the method comprising the following steps (1) - (4) content:

[0031] Step (1): Mix the silicon source, aluminum source, alkali source, and organic template in water to mix well.

[0032]One of the silicon sources comprises one of aerosol, silica, silica sol; aluminum source comprising one of metal aluminum powder, aluminum hydroxide, aluminum aluminate, trisopropanol aluminum; The source includes one or two of sodium hydroxide, potassium hydroxide, ammonia water, sodium carbonate; the organic template is an organic amine template agent. Or the silicon source and the aluminum source are ZSM-5 molecular sieves, BETA molecular sieves, USY molecular sieves or Y-type molecular sieves.

[0033] It should be noted that in this step, the copper source can be added or the copper source can be added, and the copper source is a divalent copper salt or a copper ammonia complex when the copper sour...

Embodiment 1

[0059] In this embodiment, the mother liquor wastewater recycled in ratio 1 is a solvent using a substantial mass of 50% by replacement mass. Cu-SSZ-13 molecular sieves were prepared according to the following steps.

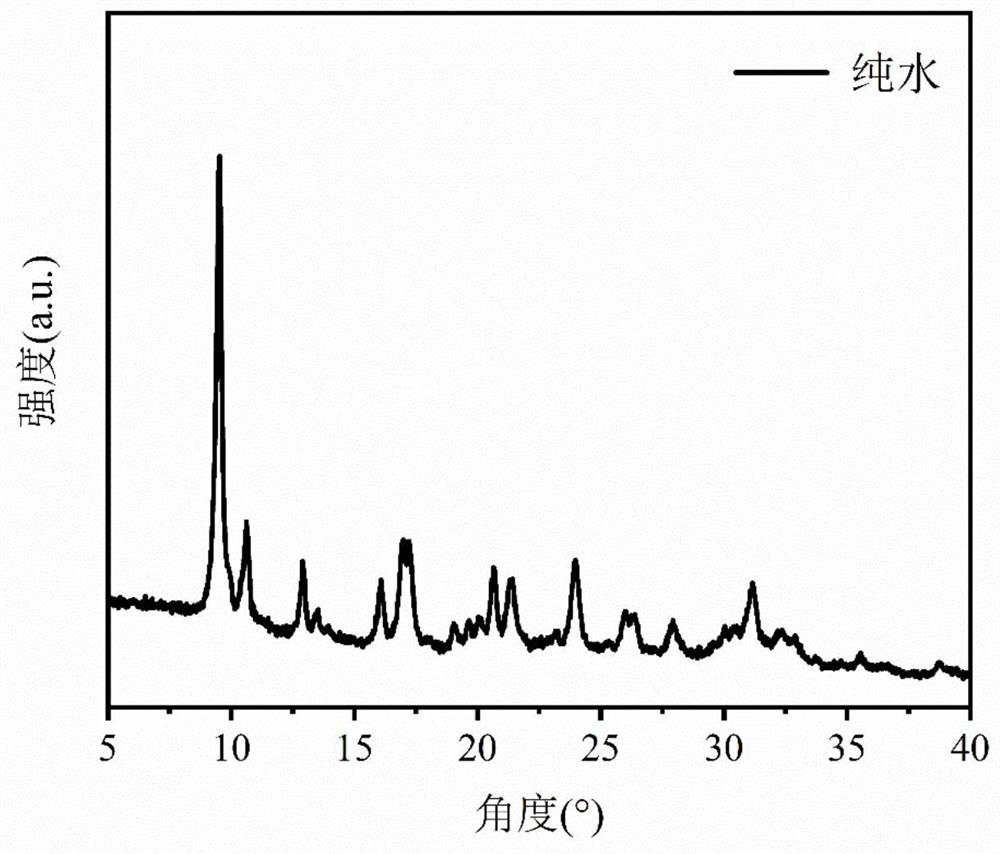

[0060] The 18.42 g of mother liquor wastewater collected in ratio 1 was mixed with 18.42 g of deionized water to obtain a mixed solvent, and SiO was measured by inductive coupling ion photometer (ICP). 2 Al 2 O 3 The content of sodium hydroxide, copper is measured by thermogravimetric analysis (Tg). These raw materials in this example are made by calculating the content of sodium aluminate, sodium hydroxide, sodium hydroxide, N, N, N-trimethylactamide, sodium hydroxide, silica sol, and Cu-TEPA, which is required to be added. The content consistent with the original addition of the original in Comparative Example 1. Then, 0.24 g of sodium hydroxide was added to the mixed solvent of mother liquor wastewater and deionized water, stirred to completely dissolve, forming ...

Embodiment 2

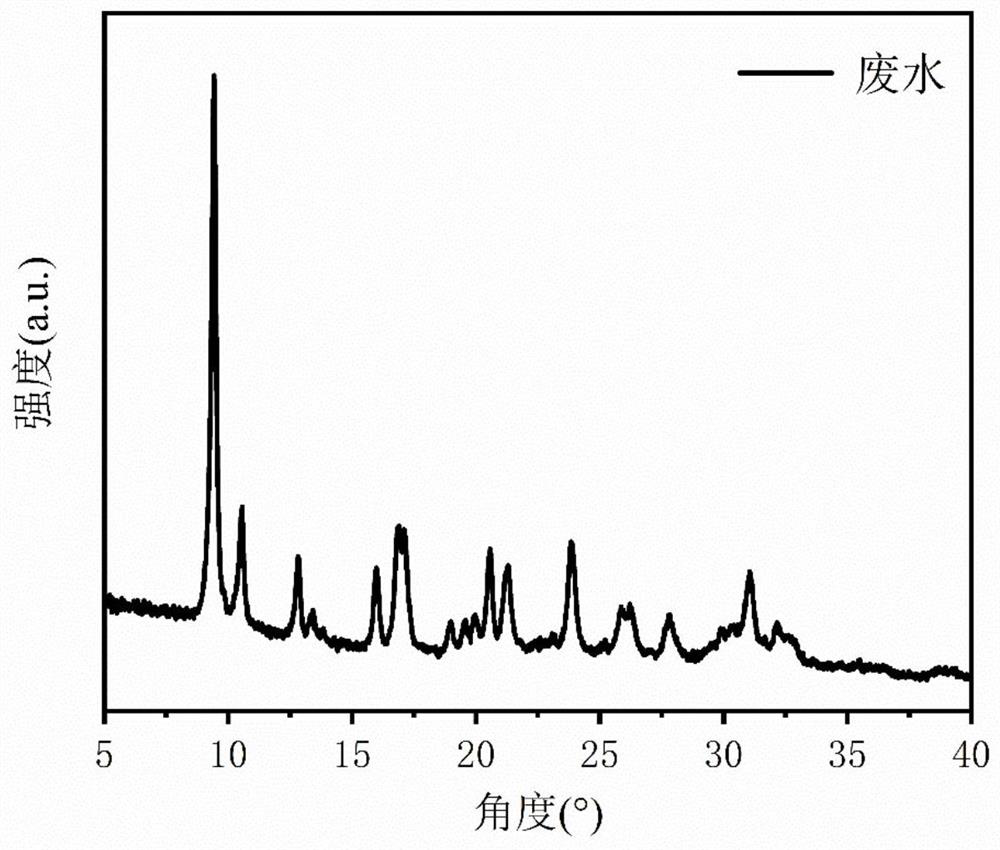

[0064] In this example, the mother liquor wastewater recycled in ratio 1 is a solvent using a substantial mass of 100% by an alternative mass. Cu-SSZ-13 molecular sieves were prepared according to the following steps.

[0065] The 36.84 g of mother liquor collected in Comparative Example 1 was used as a solvent without using deionized water. SiO in waste water parents by inductively coupled ionic meter (ICP) 2 Al 2 O 3 The content of sodium hydroxide, copper is measured by thermogravimetric analysis (Tg). These raw materials in this example are made by calculating the content of sodium aluminate, sodium hydroxide, sodium hydroxide, N, N, N-trimethylactamide, sodium hydroxide, silica sol, and Cu-TEPA, which is required to be added. The content consistent with the original addition of the original in Comparative Example 1. Then 0.12 g of sodium hydroxide was added to the mother liquor wastewater, stirred to completely dissolve, and formed an alkaline environment. 0.1 g of sodium alu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com