Refractive index tunable film structure and preparation method thereof

A technology of thin film structure and refractive index, which is applied in the field of tunable refractive index thin film structure and its preparation, can solve the problems of poor controllability of refractive index, difficult design, and lowering the refractive index of single-layer film, and achieves controllable refractive index. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Requirements of Embodiment 1: single layer SiO 2 The film refractive index was 1.1.

[0027] The design scheme of cylindrical microstructure is adopted, and the film material is SiO 2 (n=1.46), in order to facilitate the design, the height h of the microstructure is equal to the thickness H of the single layer film, and its value is 200nm. The cylindrical microstructure has a diameter of 200nm and a period of 400nm, so the duty ratio is 0.5, and the equivalent refractive index is about 1.1 according to the formula for calculating the refractive index.

[0028] Specifically, the preparation of this embodiment includes the following steps:

[0029] (1) Deposit 200nm SiO on a quartz substrate 2 layer, and scrub the film surface with acetone, then rinse with deionized water and dry;

[0030] (2) The positive photoresist was evenly coated on the SiO by spin coating method. 2 Surface, photoresist thickness is 210nm;

[0031] (3) Use double-beam interference exposure for...

Embodiment 2

[0035] Requirements of embodiment 2: single layer SiO 2 The film refractive index was 1.30.

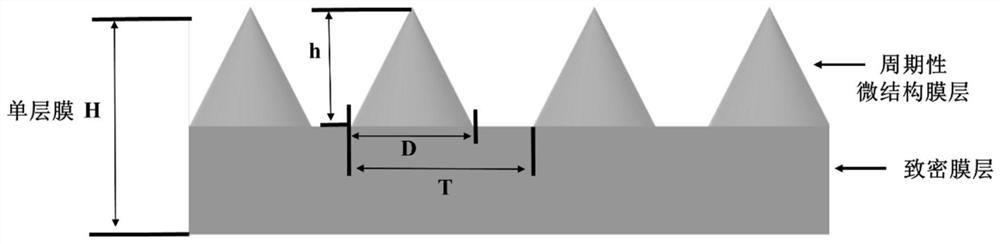

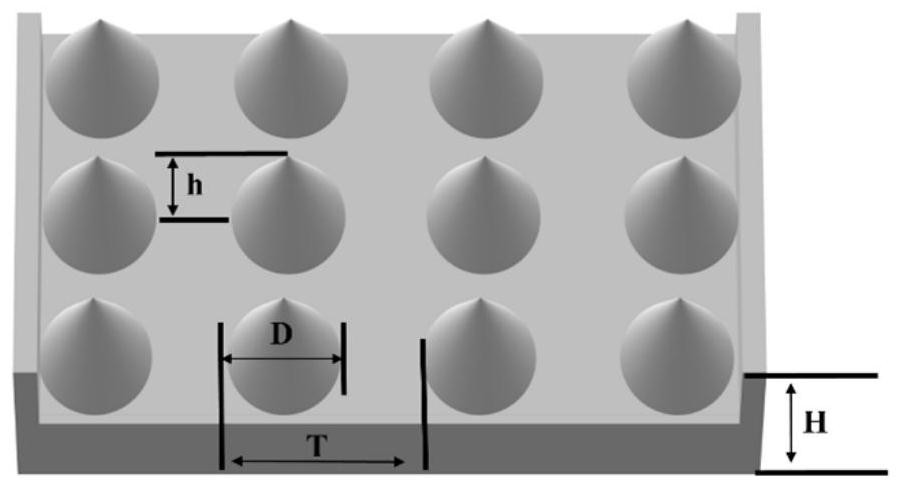

[0036] The pyramid-shaped microstructure design scheme is adopted, and the film material is SiO 2 (n=1.46), h=100nm, H=200nm. The pyramid-shaped microstructure has a diameter of 200nm and a period of 200nm, so the duty ratio is 1, and its equivalent refractive index is about 1.30 according to the formula for calculating the refractive index.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com