High molecular material decorated quantum dot single-mode optical fiber amplifier and manufacturing method thereof

A polymer material, single-mode fiber technology, used in instruments, optics, nonlinear optics, etc., can solve the problems of good size dispersion and high concentration, and achieve the effect of improving device characteristics, high compatibility, and realizing miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

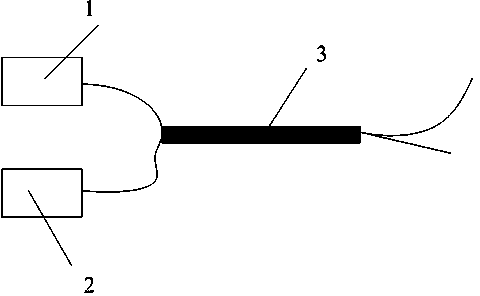

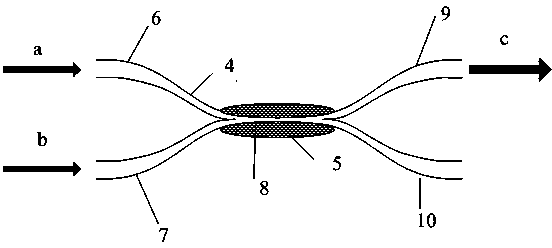

[0041] The quantum dot single-mode fiber amplifier based on the modification of polymer materials, combined with the implementation process, respectively figure 1 and figure 2 , and then to explain: one 1550nm signal light source 1, one 980nm pump light source 2 and evanescent wave amplification fiber 3 are composed. Among them, in the evanescent wave amplification fiber 3, a) is the input of signal light, b) is the input of pump light, and c) is the output of the amplified signal, and is composed of 2*2 fused taper single-mode fiber coupler 4, And based on polymer modified PbS quantum dot doped sol-gel deposition film 5 composition. The 2*2 fused-cone single-mode fiber coupler 4 is composed of a signal light input fiber 6 , a pump light input fiber 7 , a taper 8 , an amplified signal output fiber 9 , and a pump light output fiber 10 . figure 2 Among them, a is the signal light input, b is the pump light input, and c is the amplified signal output. After polymer modificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com