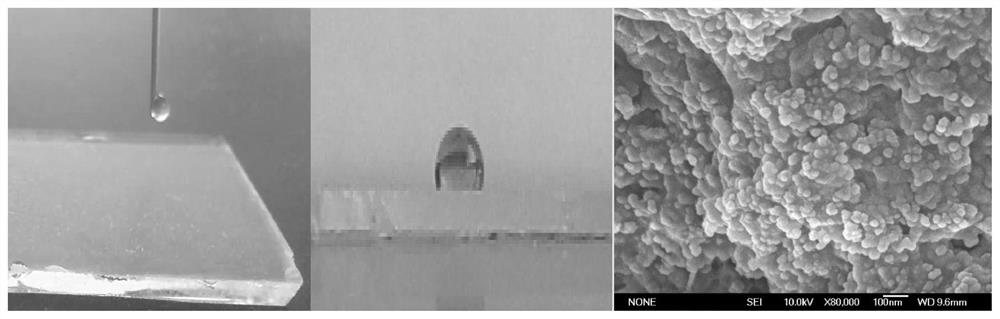

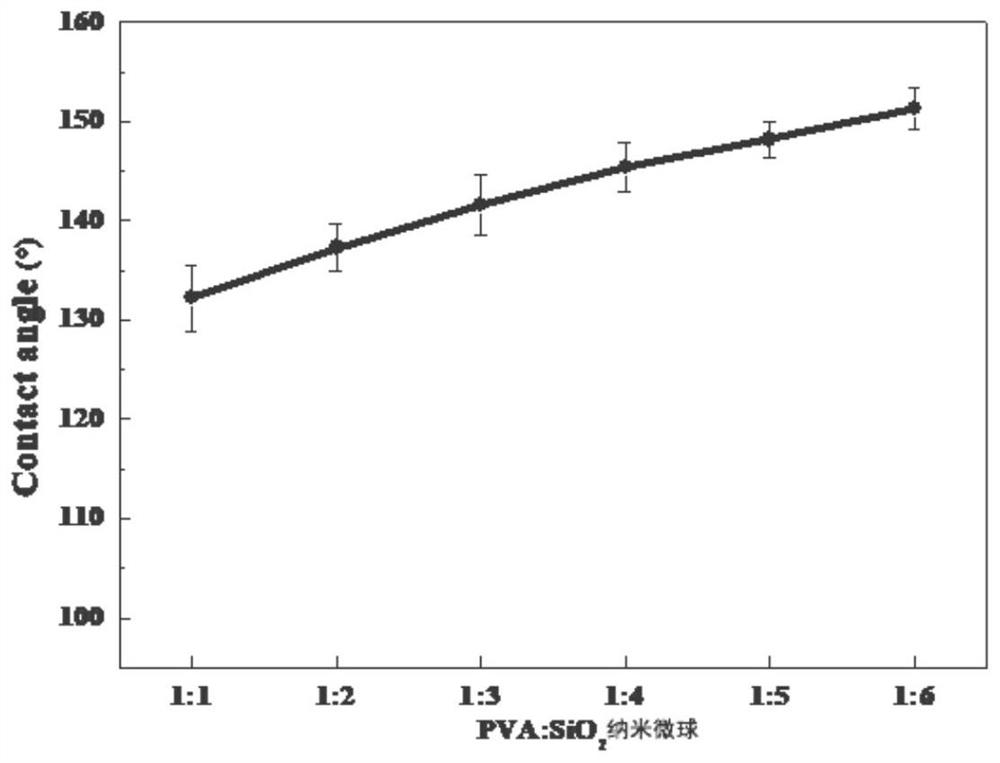

Fluorinated PVA/SiO2 super-hydrophobic membrane and preparation method thereof

A superhydrophobic and fluorinated technology, which is applied in the field of polymer modified synthetic membrane separation, can solve the problems that the surface of PVA film cannot form micro-nano rough structure, and chitosan is not easy to dissolve, so as to improve the mechanical strength, prevent agglomeration, improve The effect of hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a kind of fluorinated PVA / SiO 2 The superhydrophobic membrane and its preparation method are prepared through the following steps:

[0033] Step 1, adding an appropriate amount of SiO to the chitosan acid solution 2 , after ultrasonic treatment for 20min, chitosan / SiO 2 solution;

[0034] Step two, to chitosan / SiO 2 The solution is to drop dextran sulfate alkali solution into the bottom liquid at a certain titration rate while stirring at a rate of 300-400rpm. After the titration is completed, stir for 5 minutes. After standing for 5 hours, centrifuge at a centrifugal speed of 2000rpm for 20 minutes, and pour off the clear liquid. , and then deionized water dispersion, centrifugation twice, and finally the lower layer containing SiO 2 The nano-microspheres were freeze-dried for two days, and the samples were stored in a dry place at 4°C and protected from light until use;

[0035] Step 3: Add appropriate amount of PVA and water into a four-ne...

Embodiment 1

[0047] Add an appropriate amount of SiO with a particle size of 30nm to the chitosan formic acid solution 2 , after ultrasonic treatment for 20min, chitosan / SiO 2 solution, chitosan mass concentration 3%, SiO 2 Mass concentration 3%;

[0048] Step two, to chitosan / SiO 2 The solution is to add dextran sulfate sodium hydroxide solution dropwise at a certain titration rate to the bottom solution while stirring at a rate of 300-400rpm. After the titration is completed, stir for 5 minutes. After standing for 5 hours, centrifuge at a centrifugal speed of 2000rpm for 20 minutes, and pour it out. Clear liquid, then deionized water dispersion, centrifugation twice, and finally the lower particle size is 60nm containing SiO 2 The nano-microspheres were freeze-dried for two days, and the samples were stored in a dry place at 4°C and protected from light until use, wherein the mass concentration of dextran sulfate in the dextran sulfate sodium hydroxide solution was 4%;

[0049] Step ...

Embodiment 2

[0054] Add an appropriate amount of SiO with a particle size of 30nm in the chitosan formic acid solution 2 , after ultrasonic treatment for 20min, chitosan / SiO 2 solution, chitosan mass concentration 3%, SiO 2 Mass concentration 9%;

[0055] Step two, to chitosan / SiO 2 The solution is to add dextran sulfate sodium hydroxide solution dropwise at a certain titration rate to the bottom solution while stirring at a rate of 300-400rpm. After the titration is completed, stir for 5 minutes. After standing for 5 hours, centrifuge at a centrifugal speed of 2000rpm for 20 minutes, and pour it out. Clear liquid, then deionized water dispersion, centrifugation twice, and finally the lower layer particle size is 100nm containing SiO 2 The nano-microspheres were freeze-dried for two days, and the samples were stored in a dry place at 4°C and protected from light until use, wherein the mass concentration of dextran sulfate in dextran sulfate sodium hydroxide solution was 6%;

[0056] St...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com