Low-negative-temperature cement-based rapid repair material

A repair material, cement-based technology, applied in the field of materials, can solve the problems of slow hydration and low strength, and achieve the effects of improving slow hydration, increasing strength and shortening demoulding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

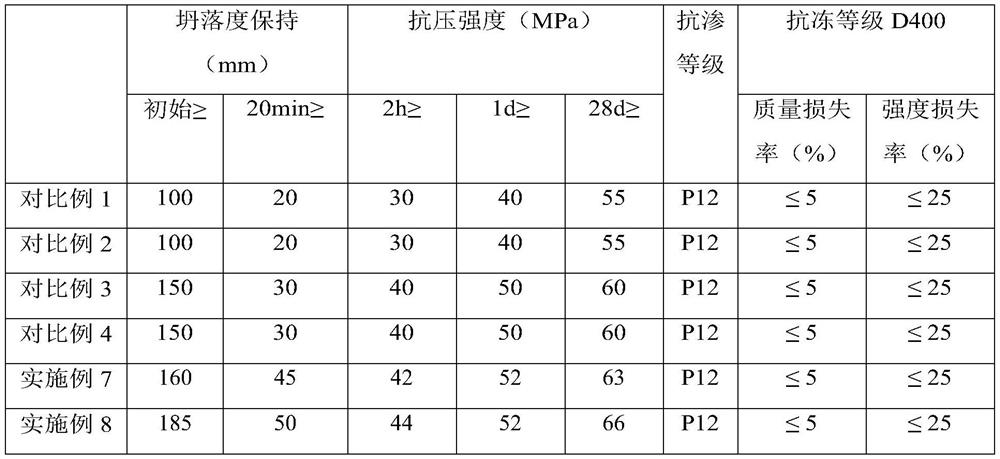

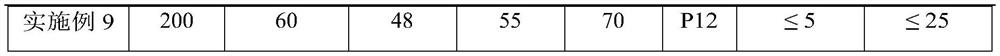

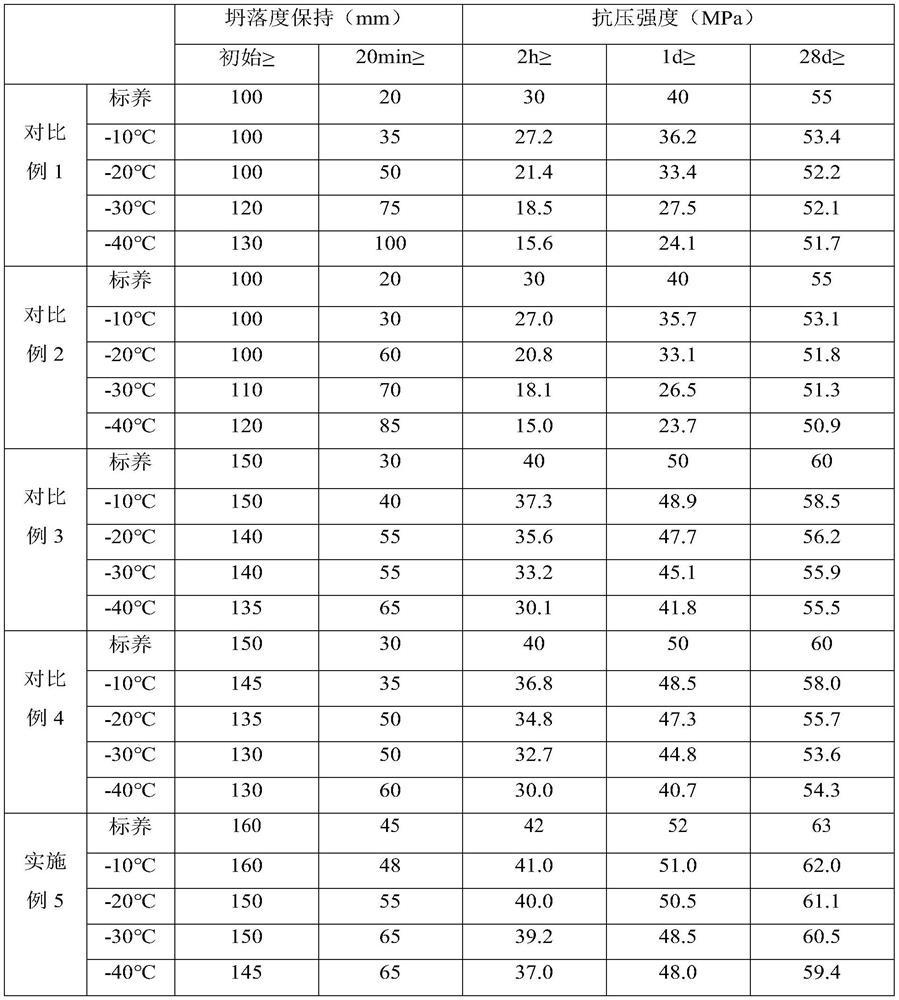

Examples

Embodiment 1

[0020] Embodiment 1 The components are synthesized according to the following parts by weight: 300 parts of ordinary portland cement, 300 parts of sulphoaluminate cement, 0 part of aluminate cement, 740 parts of medium sand, 1022 parts of crushed stone, 2.5 parts of water, 10 parts of antifreeze, 0.1 part of retarder, 0.5 part of accelerator, and 165 parts of water.

Embodiment 2

[0021] Embodiment 2 Each component synthesizes the repair material according to the following parts by weight: 300 parts of ordinary portland cement, 0 part of sulphoaluminate cement, 300 parts of aluminate cement, 740 parts of medium sand, 1022 parts of crushed stone, 2.5 parts of water, 10 parts of antifreeze, 0.1 part of retarder, 0.5 part of accelerator, and 165 parts of water.

Embodiment 3

[0022] Embodiment 3 The components are synthesized according to the following parts by weight: 0 parts of ordinary portland cement, 600 parts of sulphoaluminate cement, 0 part of aluminate cement, 735 parts of medium sand, 973 parts of crushed stone, 1.5 parts of water, 10 parts of antifreeze, 0.5 parts of retarder, 0.5 parts of accelerator, and 180 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com