Preparation method and application of hydrophobic graphene aerogel

A technology of graphene airgel and graphene hydrogel, which is applied in the direction of airgel preparation, graphene, separation methods, etc., can solve the problems of poor structural strength and high preparation cost, and achieve the effect of small steric hindrance and synthesis The effect of short time and clear synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

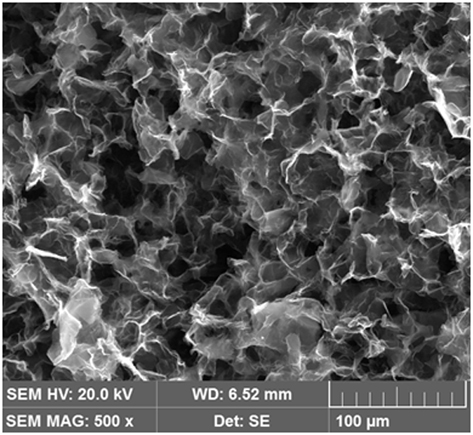

[0044] At room temperature, mix 60 mL of graphene oxide with a concentration of 12 mg / mL (based on graphite content), 20 mL of ethanol, deionized water, and 0.5 g of water-soluble starch to a total volume of 90 mL, stir for 10 minutes, and sonicate for 30 minutes to obtain a uniform mixed dispersion; adjust the pH of the mixed dispersion to 8, transfer it to a hydrothermal reaction kettle, place it at 130°C for 3 hours, cool to room temperature, and obtain a graphene hydrogel; add 25mL ethanol-trimethylchlorosilane mixed solution (V 乙醇 :V 三甲基氯硅烷 =2:3) Submerge the graphene hydrogel completely, place the hydrogel on a circular shaker at a speed of 150rpm and mix for 3 hours to obtain a graphene hydrogel uniformly infiltrated with a silane coupling agent; Continue the reaction at 80°C for 2 hours to obtain a hydrophobically modified graphene hydrogel; dry the modified graphene hydrogel at 40°C under normal pressure for 10 hours to obtain a graphene airgel; The gel was heated i...

Embodiment 2

[0046] At room temperature, 72 mL of graphene oxide with a concentration of 10 mg / mL (based on graphite content), deionized water, 10 mL of tetrahydrofuran, and 0.5 g of lactose powder were mixed to a total volume of 90 mL, stirred for 5 minutes, and ultrasonically treated for 30 minutes to obtain Uniform mixed dispersion; adjust the pH of the mixed dispersion to 9, transfer it to a hydrothermal reactor, place it at 130°C for 3 hours, cool to room temperature, and obtain a graphene hydrogel; add 20mL of ethanol-cyclohexylmethyl Dimethoxysilane mixed solution (V 乙醇 :V 环己基甲基二甲氧基硅烷 =3:1) Submerge the graphene hydrogel completely, place the hydrogel on a circular shaker at a speed of 200rpm and mix for 3 hours to obtain a graphene hydrogel uniformly infiltrated with the silane coupling agent; Continue to react at 80°C for 2 hours to obtain a hydrophobically modified graphene hydrogel; dry the modified graphene hydrogel at 60°C for 10 hours in vacuum, and continue to heat it under...

Embodiment 3

[0048] At room temperature, mix 60 mL of graphene oxide with a concentration of 12 mg / mL (based on graphite content), deionized water, 20 mL of ethanol, and 0.5 g of egg white protein powder to a total volume of 90 mL, stir for 10 minutes, and sonicate for 30 minutes to obtain Uniform mixed dispersion; adjust the pH of the mixed dispersion to 8, transfer it to a hydrothermal reaction kettle, place it at 140°C for 3 hours, cool to room temperature, and obtain a graphene hydrogel; add 15mL of ethanol-cyclohexylmethyl Dimethoxysilane mixed solution (V 乙醇 :V 环己基甲基二甲氧基硅烷 =2:1) Submerge the graphene hydrogel completely, place the hydrogel on a circular shaker at a speed of 200rpm and mix for 6 hours to obtain a graphene hydrogel uniformly infiltrated with a silane coupling agent; Continue to react at 80°C for 2 hours to obtain a graphene hydrogel hydrophobically modified by a silane coupling agent; dry the modified graphene hydrogel at 60°C under normal pressure for 8 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

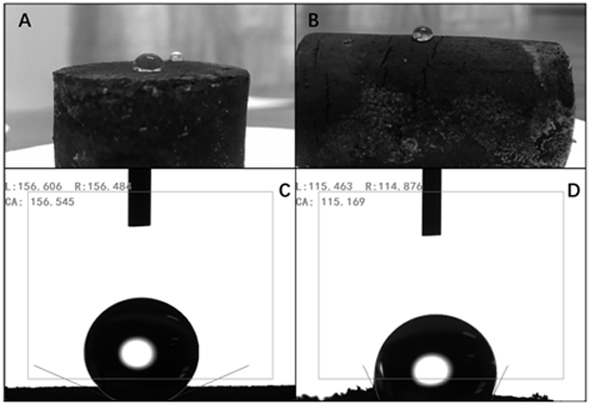

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com