Raw material conveying device for aluminum alloy production

A raw material transportation and aluminum alloy technology, which is applied in the field of raw material transportation devices for aluminum alloy production, can solve the problems of debugging distance, changing the whole, large space occupation, etc., and achieve the effect of reducing space, flexible adjustment, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

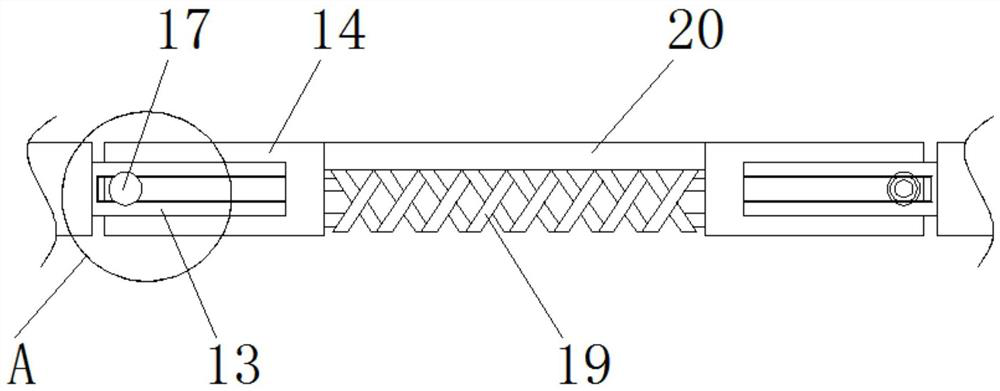

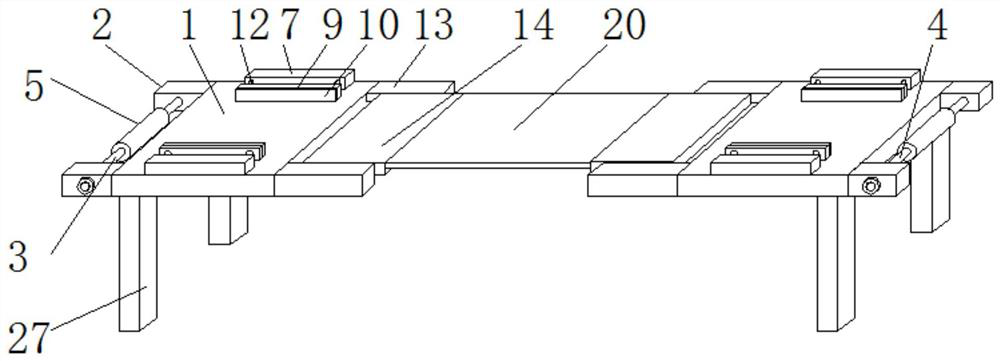

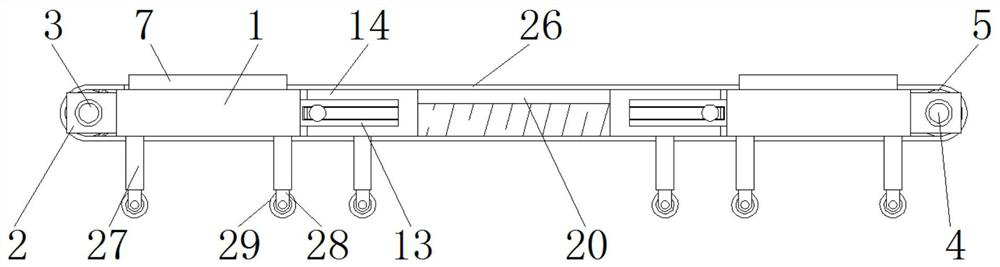

[0037] see Figure 1-6, the present invention provides a raw material conveying device for aluminum alloy production, including machine 1, the number of machine 1 is two groups, the two groups of machines 1 are distributed horizontally, and the positions of the front and rear edges of the outer wall of the side where the two groups of machines 1 are far away from each other Mounting plates 2 are welded vertically, and the rotating shaft 3 and the driven shaft 4 are connected vertically and vertically between two adjacent groups of mounting plates 2, and the outer surfaces of the rotating shaft 3 and the driven shaft 4 are fixedly sleeved with a roller 5, The roller 5 is arranged in the middle of two groups of adjacent mounting plates 2, and the roller 5 is arranged on one side of the adjacent machine 1, and the motor 6 is fixedly installed on the rear surface of the mounting plate 2 behind one side, and the rotating shaft 3 The rear end is vertically movable and connected to t...

Embodiment 2

[0039] see Figure 2-8 , the present invention provides a raw material conveying device for aluminum alloy production, including machine 1, the number of machine 1 is two groups, the two groups of machines 1 are distributed horizontally, and the positions of the front and rear edges of the outer wall of the side where the two groups of machines 1 are far away from each other Mounting plates 2 are welded vertically, and the rotating shaft 3 and the driven shaft 4 are connected vertically and vertically between two adjacent groups of mounting plates 2, and the outer surfaces of the rotating shaft 3 and the driven shaft 4 are fixedly sleeved with a roller 5, The roller 5 is arranged in the middle of two groups of adjacent mounting plates 2, and the roller 5 is arranged on one side of the adjacent machine 1, and the motor 6 is fixedly installed on the rear surface of the mounting plate 2 behind one side, and the rotating shaft 3 The rear end is vertically movable and connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com