Filtration media especially useful for filtering fluids associated with wire electron discharge machining (WEDM) processes

A filter medium, electronic discharge technology, applied in filtration and separation, membrane filters, separation devices, etc., can solve the problems of inaccurate processing, discharge interference, etc., and achieve the effect of long service life, high porosity, and low release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

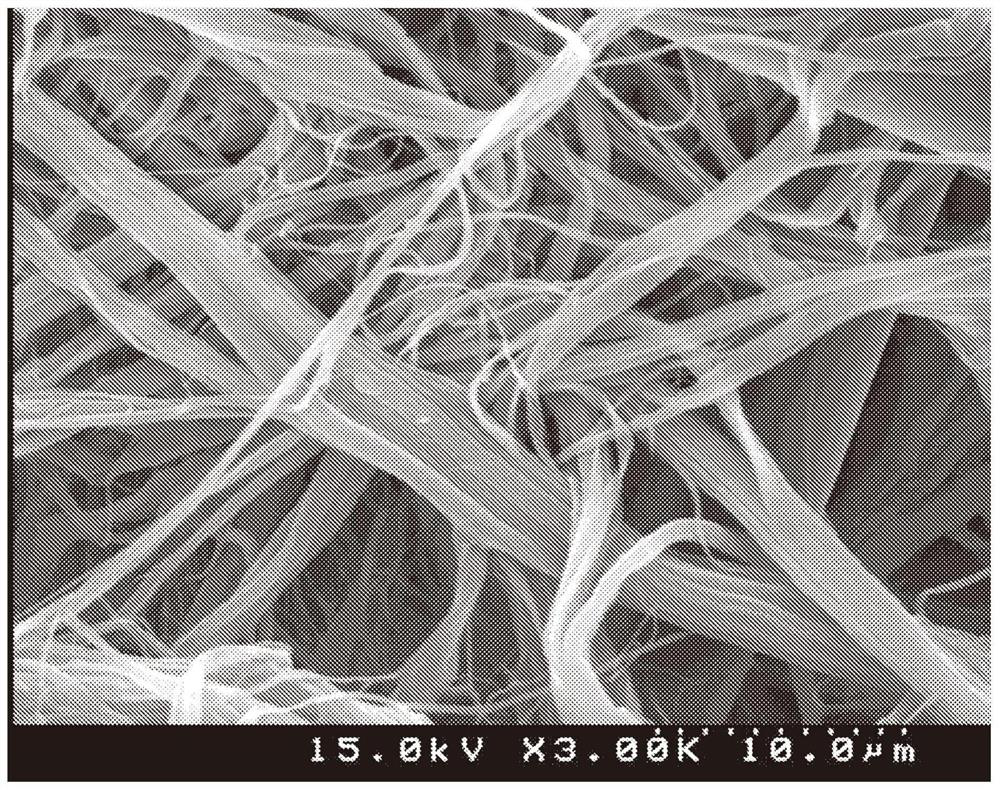

Image

Examples

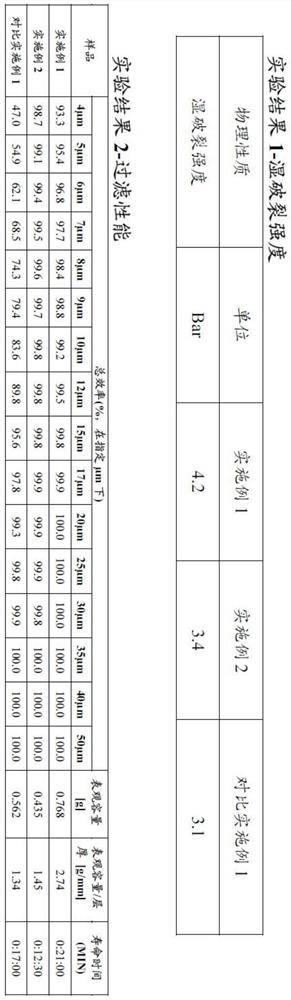

Embodiment 1

[0078] Embodiment 1 (medium of the present invention)

[0079] Monolayer media were produced with the fiber composition shown in the table below. No wet end chemicals were used other than the fibers shown in the table below. Additionally, the formed media was subjected to heated zone calendering in the absence of any added binder resin.

[0080] Example 1: Cellulosic Component

[0081] fiber type % by weight*

[0082] Teijin PET fiber 0.3dtex*5mm 25% by weight Lenzing Tencel fiber 1.7dtex*4mm 20% by weight Huvis PET two-component fiber LMF 4 denier * 6mm 30% by weight Fibrillated Lyocell Staple Fiber 25% by weight

[0083] *Based on total fiber weight

Embodiment 2

[0084] Embodiment 2 (medium of the present invention)

[0085] Two-layer media were produced with the fiber composition shown in the table below (% by weight based on total fiber weight in the media). No wet end chemicals were used other than the fibers shown in the table below. Additionally, the formed media was subjected to heated zone calendering in the absence of any added binder resin.

[0086] Example 2: Fiber Components

[0087] Top layer – 25g / m 2 , 35.7% by weight or total media basis weight

[0088] fiber type % by weight*

[0089] Eastman PET Cyphrex 10001 0.06dtex*1.5mm 30% by weight Huvis PET two-component fiber LMF 4 denier * 6mm 30% by weight Fibrillated Lyocell Staple Fiber 40% by weight

[0090] *Based on total weight of fibers in top layer

[0091] Bottom layer – 45g / m 2 , 64.3% by weight or total media basis weight

[0092] fiber type weight percentage

[0093] Toray PET fiber 0.8d*5mm 45% by weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mean flow pore size | aaaaa | aaaaa |

| Maximum aperture | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com