Modularly designed MEMS diffused silicon pressure sensor and manufacturing method thereof

A technology of diffusion silicon pressure and modular design, which is applied in the direction of fluid pressure measurement, instrumentation, and measurement force by changing the ohmic resistance, which can solve the difficulty in process control of diffusion silicon induction core packaging technology, cumbersome and complicated production process, and production Process control difficulties and other issues, to achieve the effect of improving production convenience, avoiding product pollution, and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

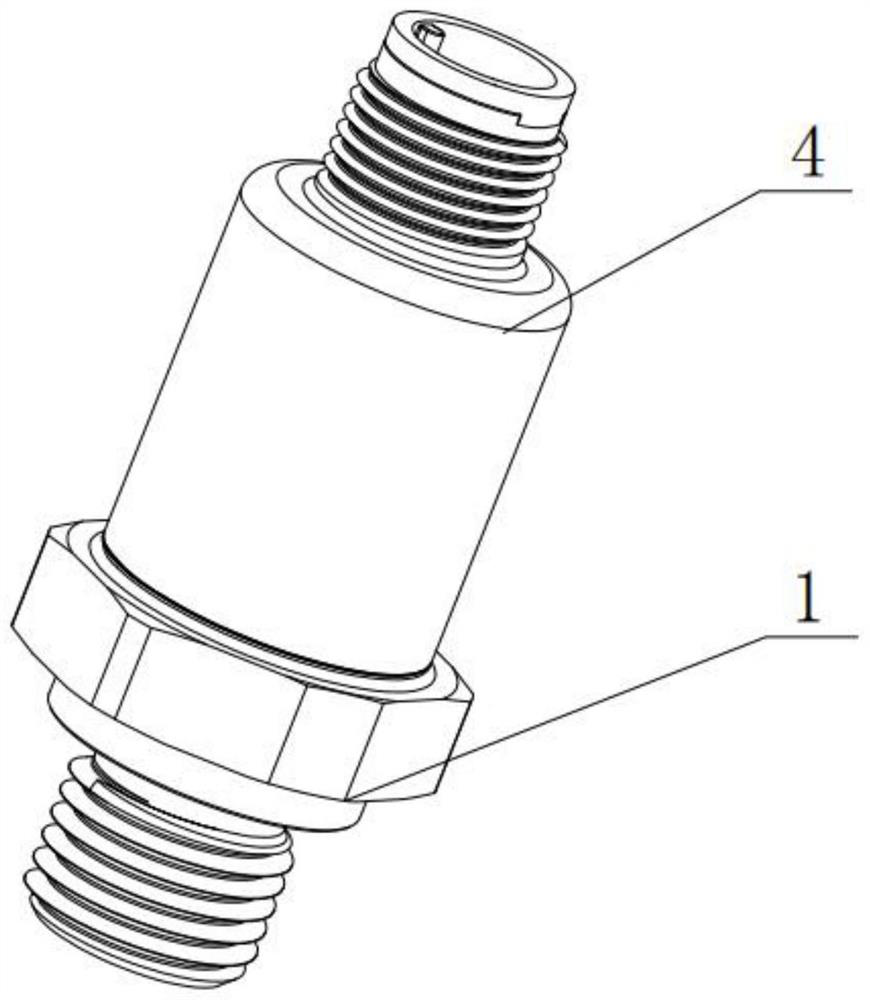

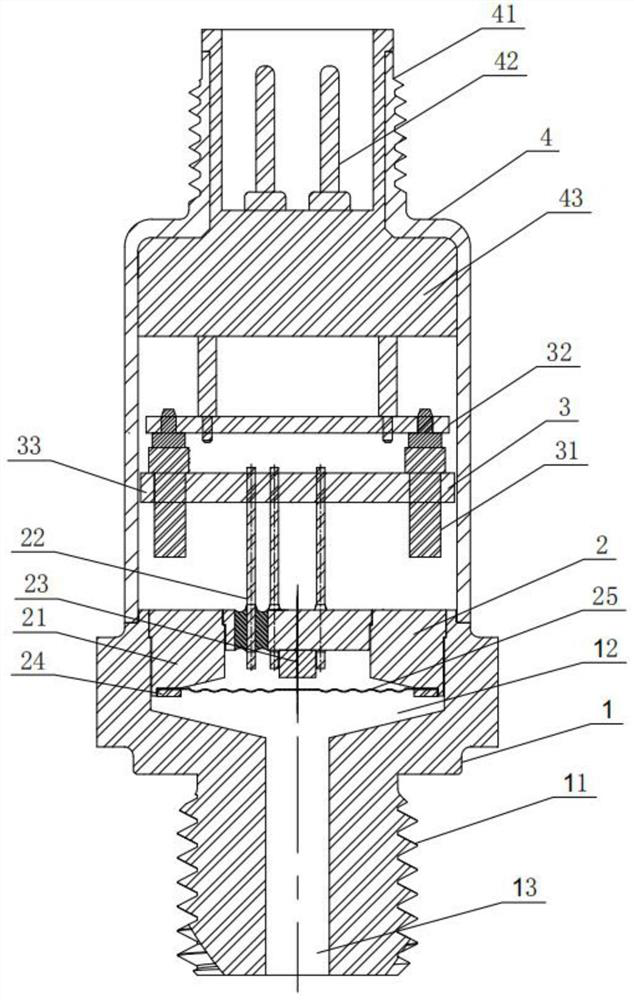

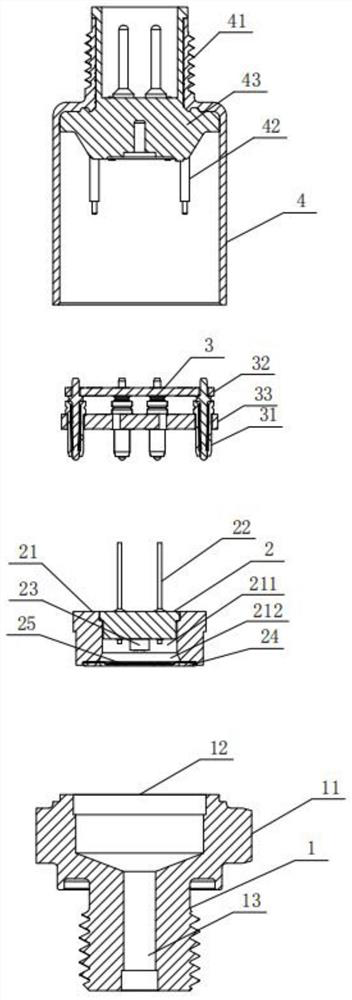

[0040] Such as Figure 1-7 As shown, a MEMS diffused silicon pressure sensor of modular design includes a pressure input module 1, a pressure sensing module 2, a signal processing module 3, and a signal output module 4; the pressure input module 1 is responsible for inputting external pressure, and the pressure The vertical center of the input module 1 is provided with a cavity; the pressure sensing module 2 is responsible for sensing and transmitting pressure signals, and the pressure sensing module 2 is embedded in the upper part of the cavity of the pressure input module 1; the signal processing module 3 is responsible for amplifying, calculating, shaping, compensating and calibrating the pressure signal, installed above the pressure sensing module 2, and connected to the top signal of the pressure sensing module 2; the signal output module 4 is responsible for docking with it The adapted industry standard connector outputs the pressure signal. The signal output module 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com