A kind of die casting aluminum alloy and its preparation method and application

A technology for casting aluminum alloys and aluminum materials, applied in the field of aluminum alloys, can solve the problems of poor thermal conductivity of aluminum alloys, and achieve the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The present invention also provides a method for preparing a die-casting aluminum alloy, which includes the following steps: according to the composition ratio of the die-casting aluminum alloy, first add aluminum-containing material into the melting furnace, and then add silicon-containing material and magnesium-containing material after the aluminum-containing material is melted. Iron-containing material, strontium-containing material, nickel-containing material or zirconium-containing material, and scandium-containing material are smelted, and then cast to obtain aluminum alloy ingots after slag removal, refining and degassing treatment, and the aluminum alloy ingots are melted and die-cast , to obtain the aforementioned die-casting aluminum alloy of the present invention.

[0039] In the present invention, the aluminum-containing material, silicon material, magnesium-containing material, iron-containing material, strontium-containing material, nickel-containing materia...

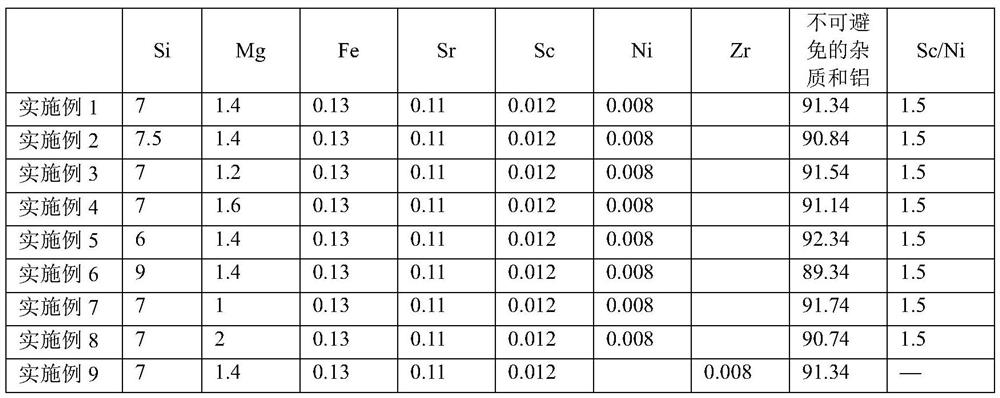

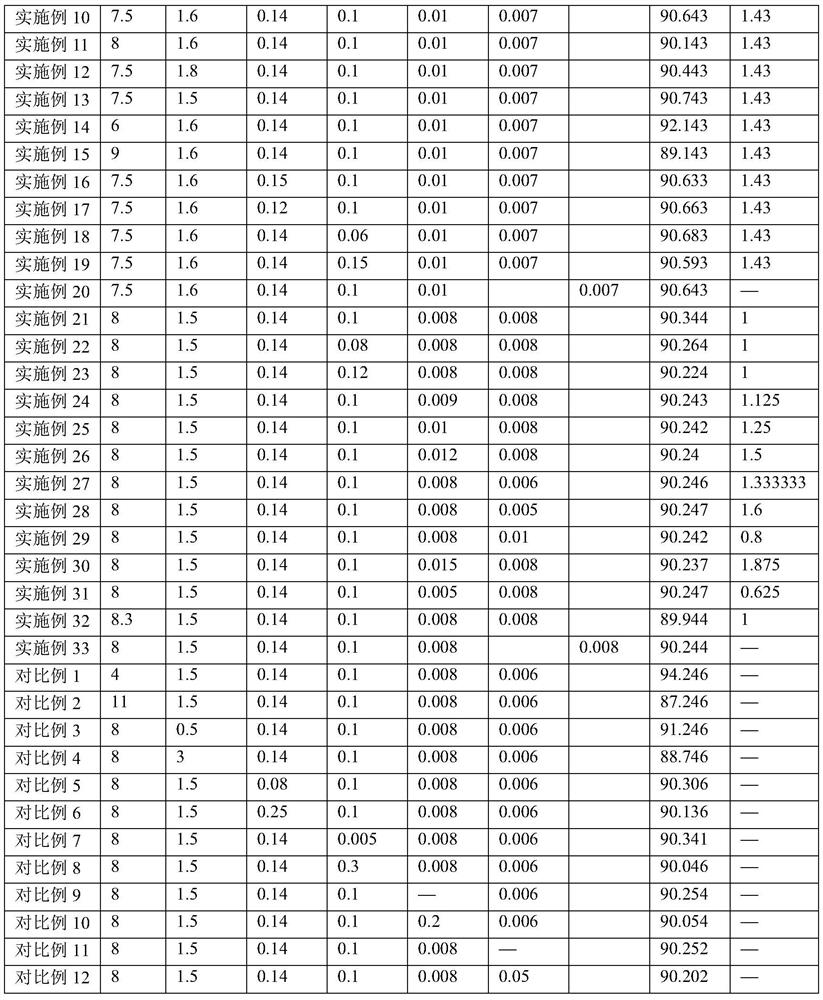

Embodiment 1-33

[0048] Prepare alloy raw materials containing various elements according to the aluminum alloy composition shown in Table 1; add pure Al to the melting furnace and smelt at 780-800°C; after pure Al is melted, add Al-Si alloy, pure Mg, Al - Fe alloy, Al-Sr alloy, Al-Sc alloy, Al-Ni alloy or Al-Zr alloy are melted at 700-710°C and stirred evenly to obtain molten metal;

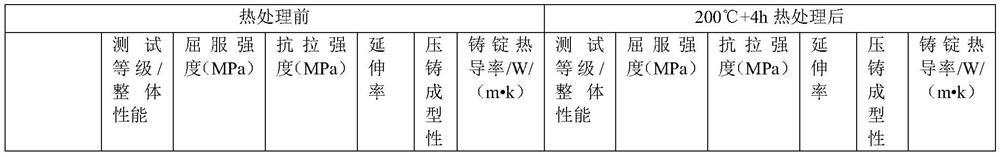

[0049] Under the condition of 700-710 ℃, add slag remover and refining agent to the molten metal, carry out slag removal, refining and degassing, until the refining agent is fully reacted, then carry out slag removal to obtain alloy melt, and cast the alloy melt The aluminum alloy ingot was obtained; the aluminum alloy ingot was melted and die-cast, and the temperature of the die-casting bath was 700-780°C; after die-casting, the die-cast aluminum alloy was heat-treated at 200°C for 4 hours, and the test results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com