A method for distributed utilization of heat in the process of producing direct reduced iron in a CDQ coupling shaft furnace

A CDQ coke oven and reduced iron technology, which is applied to the improvement of process efficiency, shaft furnaces, furnaces, etc., can solve the problems of underutilization of the reducing function of reducing gas, incorrect energy utilization, and unreasonable energy utilization, etc., to achieve improved Energy utilization efficiency, the effect of improving energy utilization efficiency and reducing heat consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

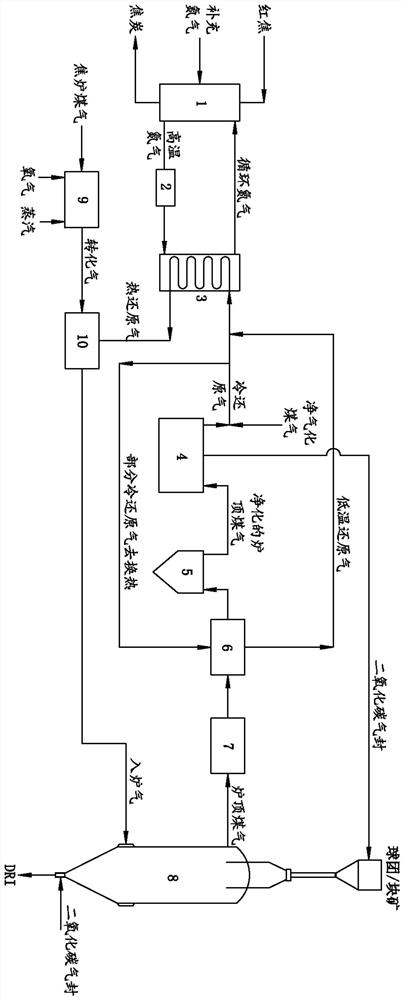

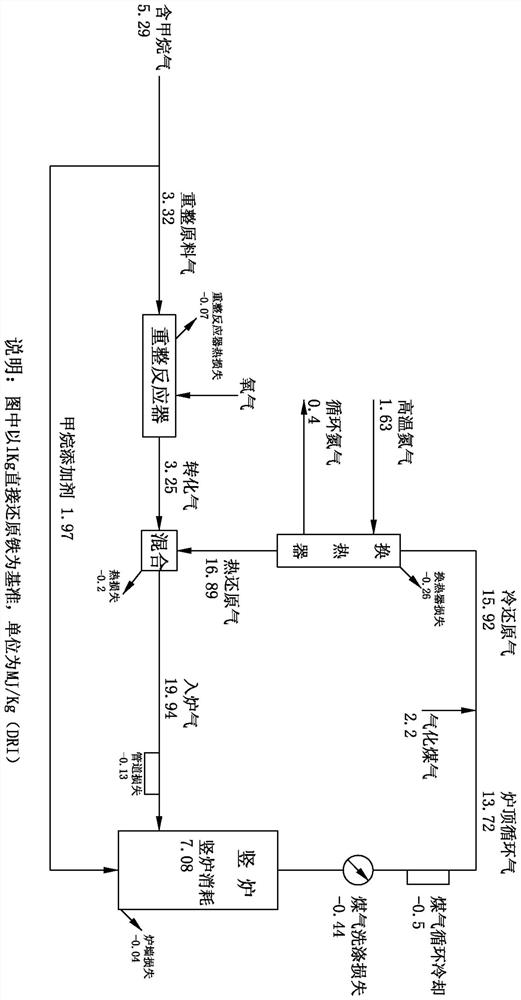

[0031] like figure 1 As shown, red coke with a temperature of about 1050°C enters CDQ oven 1, nitrogen absorbs sensible heat of red coke from bottom to top in CDQ oven 1, red coke emits heat and then discharges coke from the lower part of CDQ oven 1, After the nitrogen absorbs heat, it becomes high-temperature nitrogen, and the high-temperature nitrogen is sent to the high-temperature heat exchanger 3 through the high-temperature dust collector 2 for heat exchange with the gas from the decarburization device 4 and the purified gasification gas, and the high-temperature nitrogen becomes a temperature not greater than The circulating nitrogen at 180°C is returned to the CDQ 1 for recycling. The gas from the decarburization unit 4 is mixed with the clean gasification gas, and a part of the cold reduction gas passes through the low temperature heat exchanger 6 to recover the sensible heat of the top gas. It becomes a low temperature reducing gas of 100~300℃, and the remaining cold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com