Phase change material

A technology of phase change materials and phase change wax, which is applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of easy leakage of phase change wax, low strength and easy pulverization, low thermal conductivity, etc., and achieve thermal stability Good performance, high phase change enthalpy, fast heat conduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

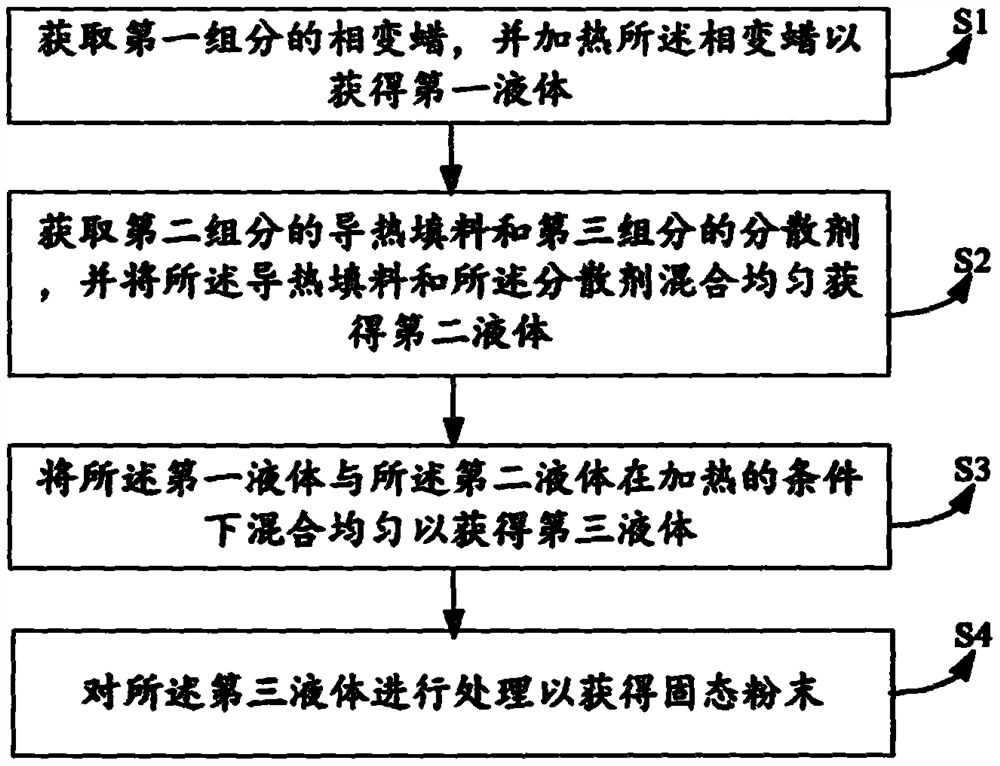

[0022] see below figure 1 The method for preparing the phase change material of the present invention is exemplified. It should be understood that the following methods are only exemplary, and any phase change material prepared by any method that includes fillers of zero-dimensional materials and one-dimensional materials and / or two-dimensional materials of the present invention can achieve the effects of the present invention .

[0023] see figure 1 , first perform step S1: obtain the phase change wax of the first component, and heat the phase change wax to obtain the first liquid.

[0024] Exemplarily, the phase change wax of the first component is measured by a balance and poured into a beaker, and heated by an electric heater. Exemplarily, the phase change wax includes one or more of higher aliphatic hydrocarbons with 12-65 free carbon atoms, higher aliphatic alcohols with 8 to 20 carbon atoms, and alkane waxes with a melting point of -15 to 140°C mixture. In this emb...

Embodiment 2

[0061] A method for preparing the phase change material of the present invention comprises: taking 6g of phase change wax and heating and melting at 60°C; taking 0.5g of phenolic resin and adding it to the phase change wax liquid; taking 5mL of absolute ethanol and stirring at room temperature; taking 0.5g of silane distillate The coupling agent was dropped into the stirred absolute ethanol, and stirred fully and evenly; 1g of carbon quantum dots, 1g of carbon nanotubes, and 0.5g of graphene were added to the stirred absolute ethanol mixture, and continued to fully stir for 0.5h after completion; Pour enough of the above solution slowly into the melted phase change wax, continue to stir and heat for 10 minutes; add 0.5g of stabilizer to the mixed wax and stir well, then raise the heating temperature to 95 degrees and continue to stir until the mixture turns until it becomes a dry solid powder; the granule powder is extruded by extrusion molding under a compression molding envir...

Embodiment 3

[0063] A method for preparing the phase change material of the present invention comprises: taking 9g of phase change wax and heating and melting at 80°C; adding 0.1g of polyether resin dropwise into the phase change wax liquid; taking about 50mL of absolute alcohol and stirring at room temperature; taking Drop about 0.1g of dispersant into the stirring alcohol, stir fully and evenly; add 0.7g foam carbon into the stirring alcohol solution, and continue to stir fully for 0.5h after completion; slowly pour the well-stirred foam carbon alcohol solution into the melted In the phase change wax, continue to stir and heat for 0.5h after completion; add 0.5g of stabilizer to the mixed wax and stir thoroughly, then raise the heating temperature to 75 degrees and continue to stir until the mixed liquid turns into a solid powder ; The granule powder is molded by molding method, and molded under 3 tons of force under the molding environment of 60 ℃.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com