Recycled polyester material and preparation method thereof

A technology of recycled polyester and polyester, which is applied in the field of recycled polyester materials and its preparation, can solve problems such as the shedding of polymer chain thermal degradation groups, affecting the recycling of waste polyester, and the poor performance of recycled polyester, so as to promote Dispersion, guaranteed anti-aging effect, high tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

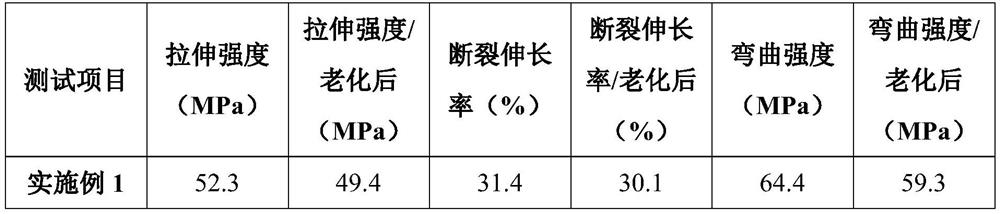

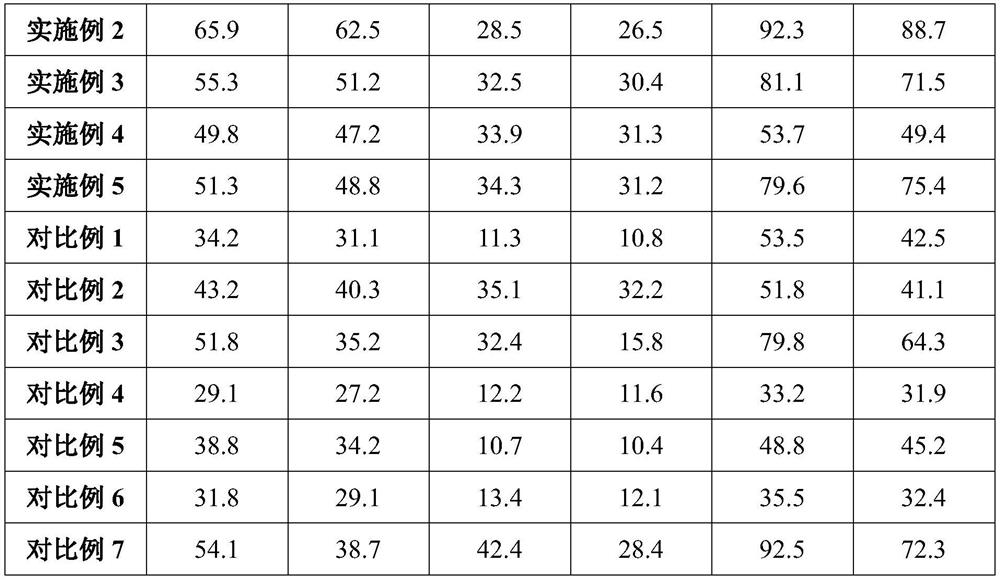

Examples

Embodiment 1

[0065] A kind of regenerated polyethylene terephthalate material, its preparation method comprises the following steps:

[0066] 1) Crushing waste polyethylene terephthalate products into particles with a particle diameter of 1 to 5 mm, then degreasing, cleaning, and drying to obtain waste polyethylene terephthalate particles;

[0067] 2) 82 parts by mass of waste polyethylene terephthalate particles, 8 parts by mass of silicon dioxide with a particle diameter of 3-15 μm, 2 parts by mass of glass fibers, 14 parts by mass of phthalic anhydride, 7 parts by mass Parts by mass of porous alumina with a particle size of 2-8 μm and 3 parts by mass of polyethylene wax were added to a high-speed mixer, and the speed of the mixer was adjusted to 600r / min, and stirred for 8 minutes, and then the materials were transferred to a twin-screw extruder, and the twin-screw extruder was adjusted to The processing temperature of the machine is 245-260°C, the screw speed is 45-50r / min, extruded and ...

Embodiment 2

[0070] A kind of regeneration polycarbonate material, its preparation method comprises the following steps:

[0071] 1) Crushing waste polycarbonate products into particles with a particle size of 1 to 5 mm, then degreasing, cleaning, and drying to obtain waste polycarbonate particles;

[0072] 2) 90 parts by mass of waste polycarbonate particles, 8 parts by mass of talcum powder with a particle diameter of 3 to 15 μm, 3 parts by mass of glass fibers, 12 parts by mass of ethylene glycol diglycidyl ether, 11 parts by mass of ethylene glycol diglycidyl ether with a particle size of 2 Add ~8μm fine-pore silica gel and 2 parts by mass of dioctyl sodium sulfonate to a high-speed mixer, adjust the speed of the mixer to 500r / min, stir for 10min, and then transfer the material to a twin-screw extruder, adjust the twin-screw extruder The processing temperature of the extruder is 225-230°C, the screw speed is 40-45r / min, extruded and granulated to obtain recycled materials;

[0073] 3)...

Embodiment 3

[0075] A kind of regeneration polybutylene terephthalate material, its preparation method comprises the following steps:

[0076] 1) Crushing waste polybutylene terephthalate products into particles with a particle diameter of 1 to 5 mm, then degreasing, cleaning, and drying to obtain waste polybutylene terephthalate particles;

[0077] 2) 98 parts by mass of waste polybutylene terephthalate particles, 13 parts by mass of talcum powder with a particle diameter of 3 to 15 μm, 4 parts by mass of glass fiber, 7 parts by mass of triphenyl phosphite, 6 parts by mass of Add one part of magnesium silicate with a particle size of 2 to 8 μm and 4 parts by mass of sucrose ester into a high-speed mixer, adjust the speed of the mixer to 700r / min, stir for 5min, and then transfer the material to a twin-screw extruder, adjust the speed of the twin-screw extruder The processing temperature is 230-240°C, the screw speed is 40-45r / min, extruded and granulated to obtain recycled materials;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com