Red copper crystalline glaze and firing method thereof

A technology of crystalline glaze and red copper color, which is applied in the field of ceramic glaze, can solve the problems that affect the mass production of crystalline glaze, the lack of adaptability between glaze surface and green body, and the poor temperature resistance of crystalline glaze, so as to achieve the goal of not easy peeling and The effect of cracking, bright color and smooth glaze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

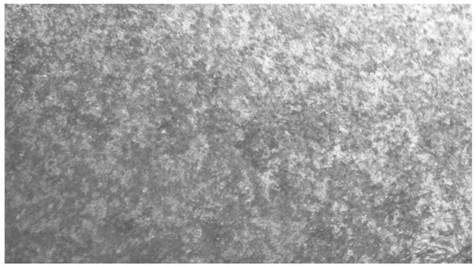

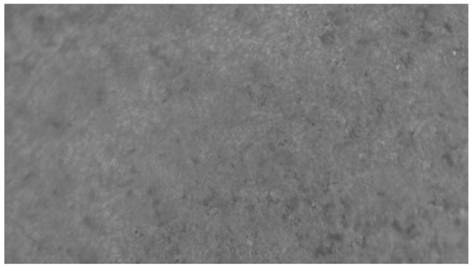

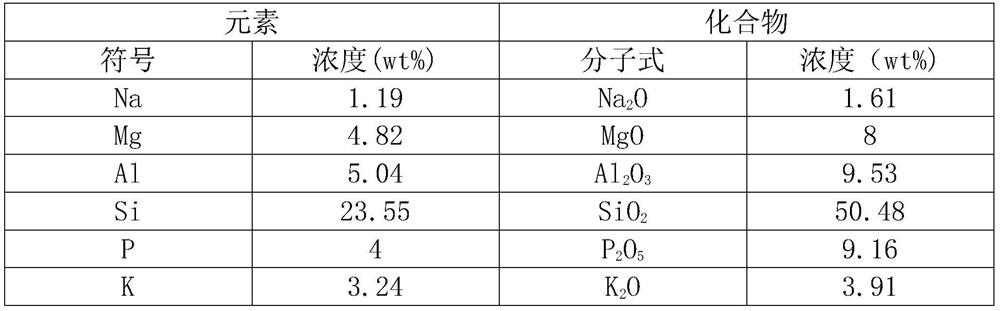

Image

Examples

Embodiment 1

[0026] This embodiment provides a copper-colored crystalline glaze, which is fired by using the following raw materials in parts by weight:

[0027] 48 parts by weight of Linggen porcelain stone from Longquan, 4 parts by weight of Longquan limestone, 6 parts by weight of talc, 10 parts by weight of Hunan potassium feldspar, 13 parts by weight of Hunan iron oxide red, 14 parts by weight of bovine bone ash, and 5 parts by weight of Longyan kaolin.

[0028] The firing method of the copper-colored crystalline glaze comprises the steps of:

[0029] (1) Take the Linggen porcelain stone, Longquan limestone, talc, Hunan potassium feldspar, Hunan iron oxide red, ox bone ash, Longyan kaolin of Longquan, carry out wet ball milling after each raw material is mixed (raw material after mixing: ball: Water=1:1.5:1), obtain the solid particle size and be 80 mesh sieve surplus 0.1%, the glaze slurry that concentration table measures concentration is 49 degree;

[0030] (2) Apply the glaze slu...

Embodiment 2

[0039] This embodiment provides a copper-colored crystalline glaze, which is fired by using the following raw materials in parts by weight:

[0040] 45 parts by weight of Linggen porcelain stone from Longquan, 3 parts by weight of Longquan limestone, 5 parts by weight of talc, 12 parts by weight of Hunan potassium feldspar, 15 parts by weight of Hunan iron oxide red, 16 parts by weight of bovine bone ash, and 4 parts by weight of Longyan kaolin.

[0041] The firing method of the copper-colored crystalline glaze comprises the steps of:

[0042] (1) Take Longquan's Linggen porcelain stone, Longquan limestone, talc, Hunan potassium feldspar, Hunan iron oxide red, bovine bone ash, Longyan kaolin, carry out wet ball milling after each raw material is mixed (raw material after mixing: ball: Water=1:1.5:0.8), obtain the solid particle size and be 60 mesh sieve surplus 0.1%, the glaze slurry that concentration table measures concentration is 48 degree;

[0043] (2) Apply the glaze sl...

Embodiment 3

[0047] This embodiment provides a copper-colored crystalline glaze, which is fired by using the following raw materials in parts by weight:

[0048] 52 parts by weight of Linggen porcelain stone from Longquan, 5 parts by weight of Longquan limestone, 7 parts by weight of talc, 8 parts by weight of Hunan potassium feldspar, 10 parts by weight of Hunan iron oxide red, 12 parts by weight of bovine bone ash, and 6 parts by weight of Longyan kaolin.

[0049] The firing method of the copper-colored crystalline glaze comprises the steps of:

[0050] (1) Take the Linggen porcelain stone, Longquan limestone, talc, Hunan potassium feldspar, Hunan iron oxide red, ox bone ash, Longyan kaolin of Longquan, carry out wet ball milling after each raw material is mixed (raw material after mixing: ball: Water=1:1.5:1.2), obtain the solid particle size and be 100 mesh sieve surplus 0.1%, the glaze slurry that concentration table measures concentration is 50 degree;

[0051] (2) Apply the glaze s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com