Method for controllably preparing NaVO2 nanosphere sodium storage electrode material

An electrode material and nanosphere technology, which is applied in the field of controllable preparation of NaVO2 nanosphere sodium storage electrode materials, can solve the problems of insufficient reaction, high energy loss, uneven heating, etc., and achieves low preparation cost, improved capacity and size. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

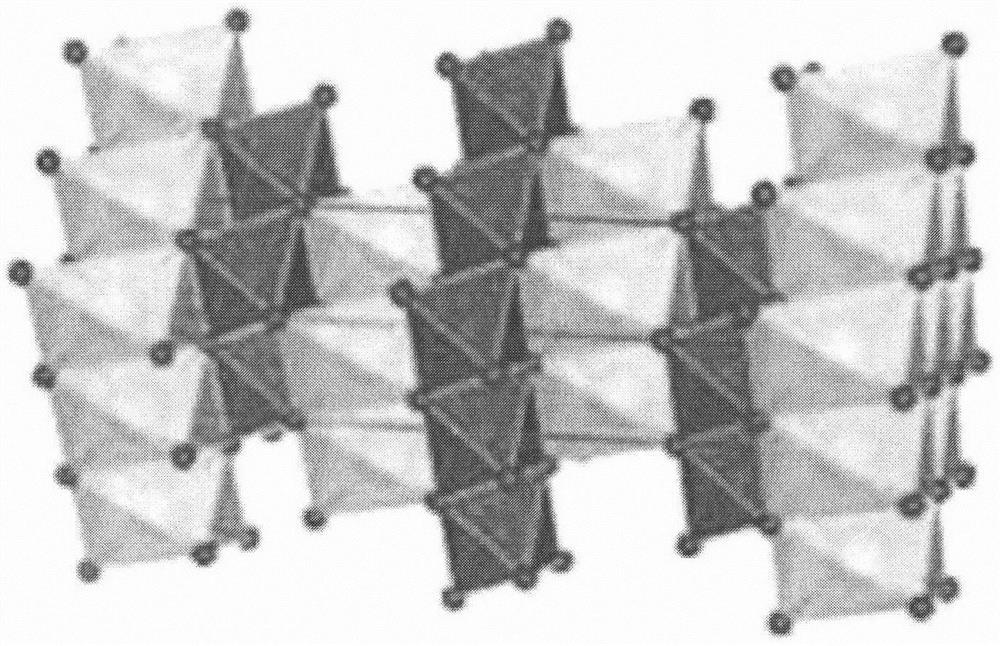

Image

Examples

Embodiment 1

[0019] Embodiment 1: a precursor compact sheet with a thickness of 4 mm, with 200 watts of microwave radiation power, to prepare NaVO 2 Nanosphere electrode material

[0020] Accurately weigh 10.0000g of analytically pure V 2 o 5 Powder, the particle size of which is 200 mesh; at the same time, accurately weigh and analyze pure Na 2 CO 3 5.8275g of 5.8275g, its mesh number is 200 mesh; The above-mentioned two kinds of materials are fully mixed for 20min, and then this mixture is added into a stainless steel ball mill tank with a volume of 100ml, and the diameter of the stainless steel grinding balls added is 5mm, and the ball-to-material ratio is adjusted to be 1 : 1, adjust the rotating speed 100rpm of planetary ball mill, control the mixing temperature of grinding 50 ℃, the interval time of forward rotation and reverse rotation of ball mill is 15 minutes, the total ball milling time is 2h, separate ball mill tank and uniform powder material; 10mm is for the tableting mol...

Embodiment 2

[0023] Embodiment 2: a precursor compact sheet with a thickness of 4 mm, with 850 watts of microwave radiation power, to prepare NaVO 2 Nanosphere electrode material

[0024] Accurately weigh 10.0000g of analytically pure V 2 o 5 Powder, the particle size of which is 200 mesh; at the same time, accurately weigh and analyze pure Na 2 CO 3 5.8275g of 5.8275g, its mesh number is 200 mesh; The above-mentioned two kinds of materials are fully mixed for 20min, and then this mixture is added into a stainless steel ball mill tank with a volume of 100ml, and the diameter of the stainless steel grinding balls added is 5mm, and the ball-to-material ratio is adjusted to be 1 : 1, adjust the rotating speed 100rpm of planetary ball mill, control the mixing temperature of grinding 40 ℃, the interval time of forward rotation and reverse rotation of ball mill is 15 minutes, the total ball milling time is 2h, separate ball mill tank and uniform powder material; 10mm is for the tableting mol...

Embodiment 3

[0027] Embodiment 3: the thickness is the precursor compact sheet of 4mm, with 1500 watts of microwave radiation power, make NaVO 2 Nanosphere electrode material

[0028] Accurately weigh 10.0000g of analytically pure V 2 o 5 Powder, the particle size of which is 200 mesh; at the same time, accurately weigh and analyze pure Na 2 CO 3 5.8275g of 5.8275g, its mesh number is 200 mesh; The above-mentioned two kinds of materials are fully mixed for 20min, and then this mixture is added into a stainless steel ball mill tank with a volume of 100ml, and the diameter of the stainless steel grinding balls added is 5mm, and the ball-to-material ratio is adjusted to be 1 : 1, adjust the rotating speed 100rpm of planetary ball mill, control the mixing temperature of grinding 50 ℃, the interval time of forward rotation and reverse rotation of ball mill is 15 minutes, the total ball milling time is 2h, separate ball mill tank and uniform powder material; 10mm is for the tableting mold to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com