Graphene-based lithium ion battery negative electrode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of increasing ion conduction paths, increasing battery costs, easy accumulation or agglomeration, etc., to improve the first Coulombic efficiency , good cycle performance and high coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

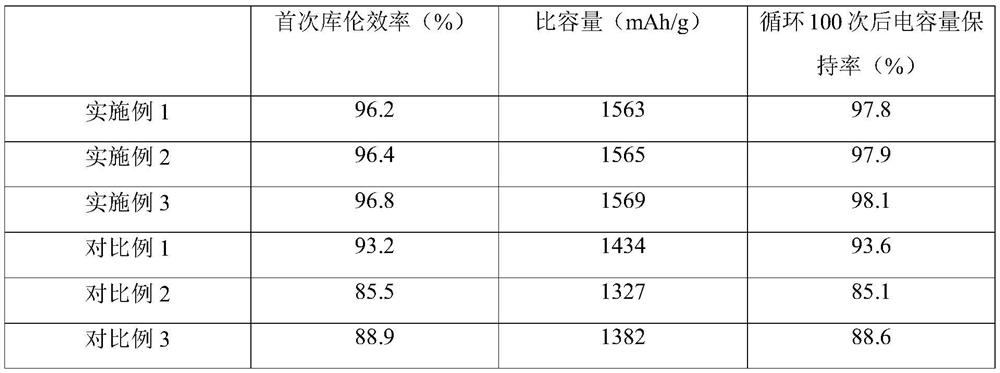

Examples

Embodiment 1

[0034] A preparation method of a graphene-based lithium ion battery negative electrode material, comprising the steps of:

[0035] (1) First modify niobium and tin-doped graphene with 7-octenyltrichlorosilane to obtain silanized graphene;

[0036] (2) react silanized graphene with 4-bromo-2-(2-nitro-1-propenyl)thiophene to obtain modified graphene;

[0037] (3) Finally, the modified graphene and 2-vinyl thiophene are used as raw materials for polymerization to obtain a graphene-based negative electrode material for lithium-ion batteries;

[0038]Wherein, the niobium and tin-doped graphene is made from niobium pentachloride, tin tetrachloride and liquid polyacrylonitrile in a mass ratio of 0.01:0.05:1.

[0039] The preparation method of niobium and tin-doped graphene is as follows: first add niobium pentachloride and tin tetrachloride to hydrochloric acid solution with a mass concentration of 36%, and ultrasonically oscillate evenly, then add a 40% aqueous ethanol solution wit...

Embodiment 2

[0051] A preparation method of a graphene-based lithium ion battery negative electrode material, comprising the steps of:

[0052] (1) First modify niobium and tin-doped graphene with 7-octenyltrichlorosilane to obtain silanized graphene;

[0053] (2) react silanized graphene with 4-bromo-2-(2-nitro-1-propenyl)thiophene to obtain modified graphene;

[0054] (3) Finally, the modified graphene and 2-vinyl thiophene are used as raw materials for polymerization to obtain a graphene-based negative electrode material for lithium-ion batteries;

[0055] Wherein, the niobium and tin-doped graphene is made from niobium pentachloride, tin tetrachloride and liquid polyacrylonitrile in a mass ratio of 0.02:0.03:1.

[0056] The preparation method of niobium and tin-doped graphene is as follows: first add niobium pentachloride and tin tetrachloride to hydrochloric acid solution with a mass concentration of 38%, and ultrasonically oscillate evenly, then add a 30% ethanol aqueous solution wi...

Embodiment 3

[0068] A preparation method of a graphene-based lithium ion battery negative electrode material, comprising the steps of:

[0069] (1) First modify niobium and tin-doped graphene with 7-octenyltrichlorosilane to obtain silanized graphene;

[0070] (2) react silanized graphene with 4-bromo-2-(2-nitro-1-propenyl)thiophene to obtain modified graphene;

[0071] (3) Finally, the modified graphene and 2-vinyl thiophene are used as raw materials for polymerization to obtain a graphene-based negative electrode material for lithium-ion batteries;

[0072] Wherein, the niobium and tin-doped graphene is made from niobium pentachloride, tin tetrachloride and liquid polyacrylonitrile in a mass ratio of 0.015:0.04:1.

[0073] The preparation method of niobium and tin-doped graphene is as follows: first add niobium pentachloride and tin tetrachloride to hydrochloric acid solution with a mass concentration of 37%, and ultrasonically oscillate evenly, then add a 35% ethanol aqueous solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com