Method for rapidly removing ammonia nitrogen by using extreme environment microalgae non-sterilization fermentation method, and application thereof

A kind of extreme environment, fermentation technology, applied in the field of rapid ammonia nitrogen removal, can solve the problems of high efficiency, low cost treatment and high value resource utilization of unfavorable wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] Example 1 Adaptive cultivation of ultra-high ammonia-nitrogen industrial waste water to thiophilic Prototheca

[0090] 1.1 Activation of algal species

[0091] Single algae colonies of thiaphophilic primordial red algae (Galdieria sulphuraria UTEX 2919) were picked out from the solid medium and inoculated in the 2MA medium after adjusting the formula for cultivation. The pH value of the medium was 2.5, and the glucose concentration was 20g / L. At a culture temperature of 35 °C and a light intensity of 210 μmol m -2 the s -1 , cultured in a constant temperature light shaker with a rotational speed of 150 rpm (cultivated to the logarithmic growth phase). Wherein, the formula of 2MA medium after formula adjustment is shown in Table 1.

[0092] 2MA medium formula after adjusting the formula in table 1

[0093]

[0094]

[0095] Note: EDTA is ethylenediaminetetraacetic acid; in the original 2MA medium formula (NH 4 ) 2 SO 4 The concentration is 2.62g / L.

[0096]...

Embodiment 2

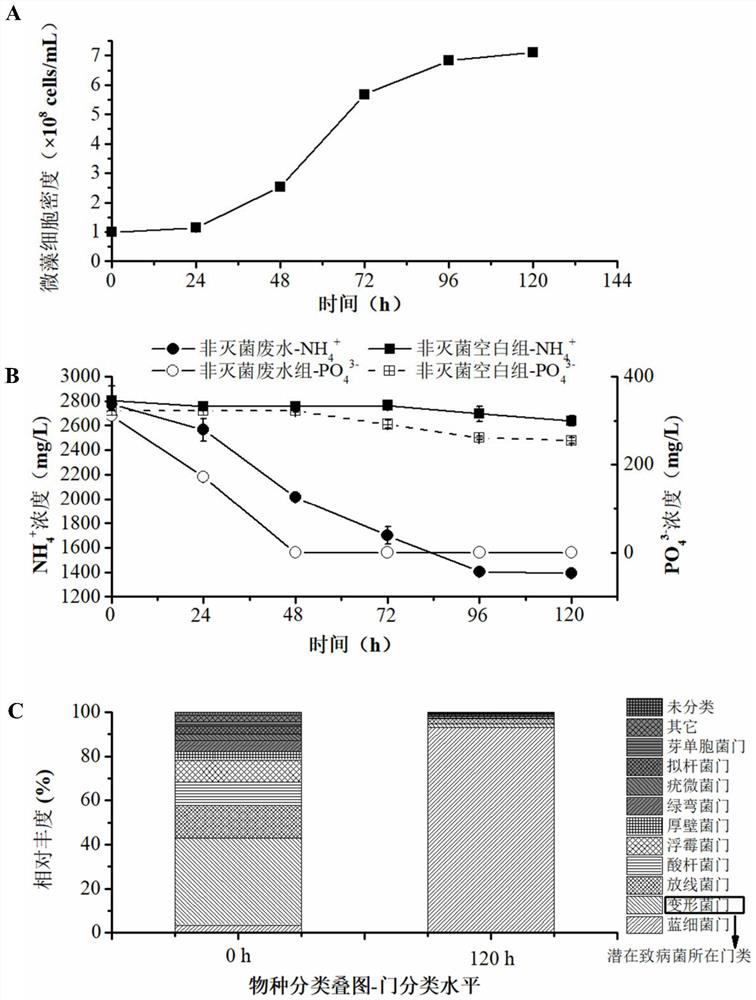

[0103] Example 2 The effect of non-sterile culture system on the ammonia nitrogen removal efficiency of thiaphilic red algae

[0104] 2.1 Activation of algal species and preparation of wastewater medium

[0105] The preparation of the activated red algae (Galdieria sulphuraria UTEX 2919) and the non-sterile ultra-high ammonia nitrogen wastewater medium were carried out according to the methods described in 1.1 and 1.2, respectively.

[0106] 2.2 Non-sterile culture system for the cultivation of thiaphilic Rhodophyta

[0107] 2.2.1 Mixed cultivation: Inoculate the algae into a conical flask containing 100mL (volume 250mL) non-sterile ultra-high ammonia nitrogen wastewater medium, where the initial ammonia nitrogen concentration is 2800mg / L, and non-inoculated red algae The sterilized wastewater medium was used as the blank group. The inoculation density of red algae in the culture system was 1×10 8 cells / ml, the pH value of the medium is 2.5, and the glucose concentration is...

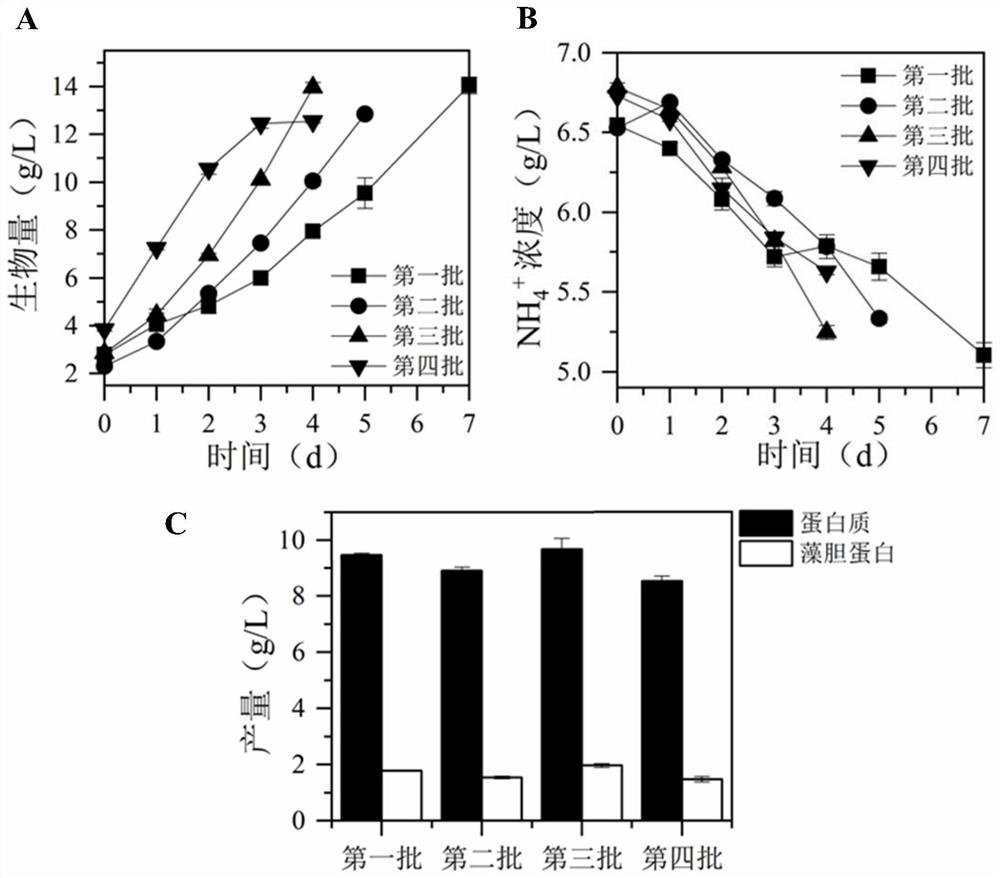

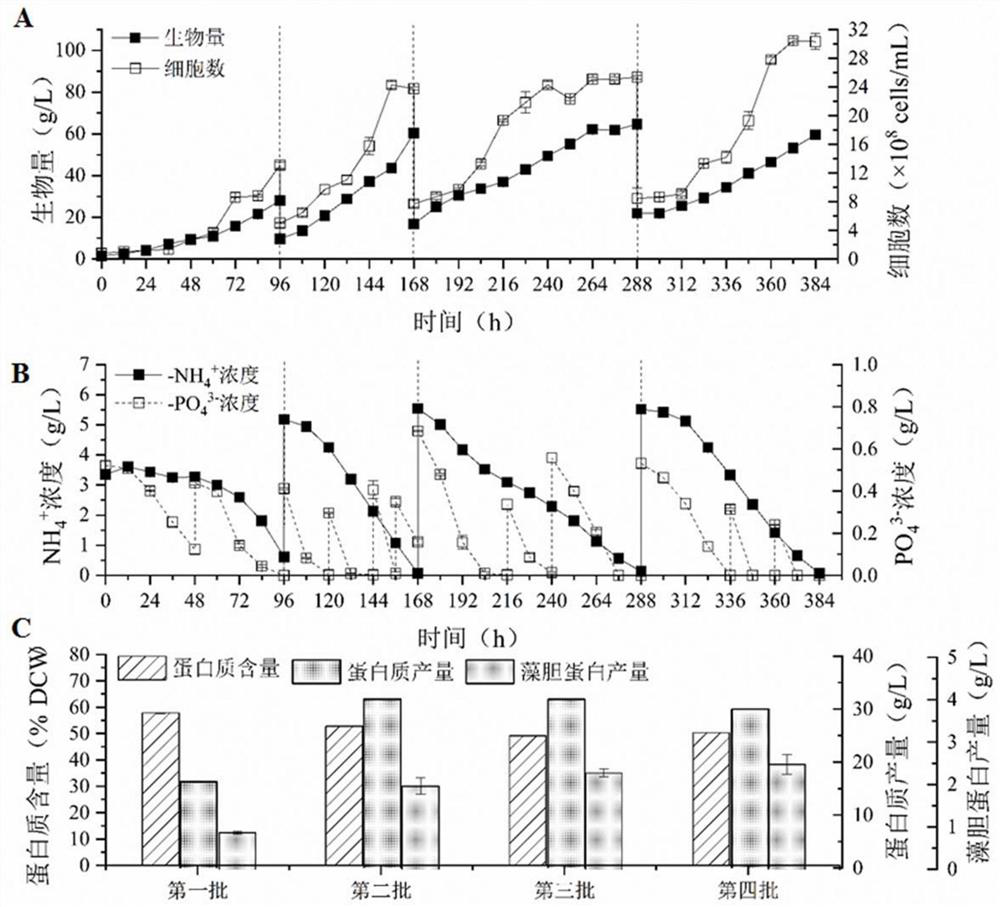

Embodiment 3

[0110] Example 3 Continuous treatment of ultra-high ammonia-nitrogen industrial wastewater by thiophilic red algae in a fermenter culture system

[0111] 3.1 Activation of algal species and preparation of wastewater medium

[0112] The preparation of the activated and non-sterilized ultra-high ammonia nitrogen wastewater medium of thiaphophilic primordial red algae (Galdieria sulphuraria UTEX 2919) was carried out according to the methods described in 1.1 and 1.2, respectively.

[0113] 3.2 Four-stage fermenter culture

[0114] 3.2.1 Photofermentation culture: inoculate the red algae after 1.3 adaptive culture in Example 1 into non-sterile ultra-high ammonia nitrogen wastewater medium, and place it in a 5L fermenter (containing 3.5L wastewater medium) for cultivation . The initial inoculum density of photofermentation in red algae was 1×10 8 cells / ml, the pH value of the medium is 2.5, the temperature is 35°C, the stirring rate is 150r / min, the ventilation volume is 150L / h,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com