Deburring equipment for aluminum alloy castings

An aluminum alloy and burr technology is applied in the field of deburring equipment for aluminum alloy castings, which can solve the problems of affecting the stability of the clamping and installation of the articles, reducing the cleanliness of the finished product, and inconvenient loading and unloading operations, so as to enhance the anti-shedding effect and improve the Tightness, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

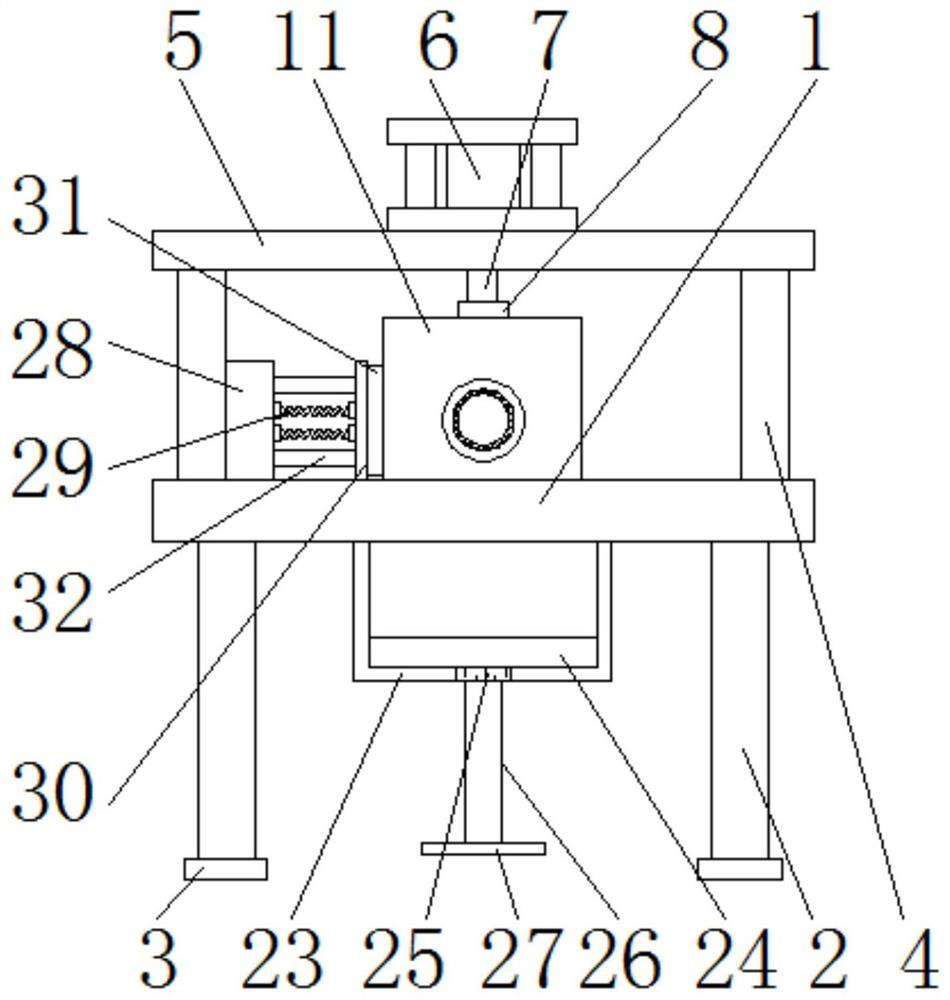

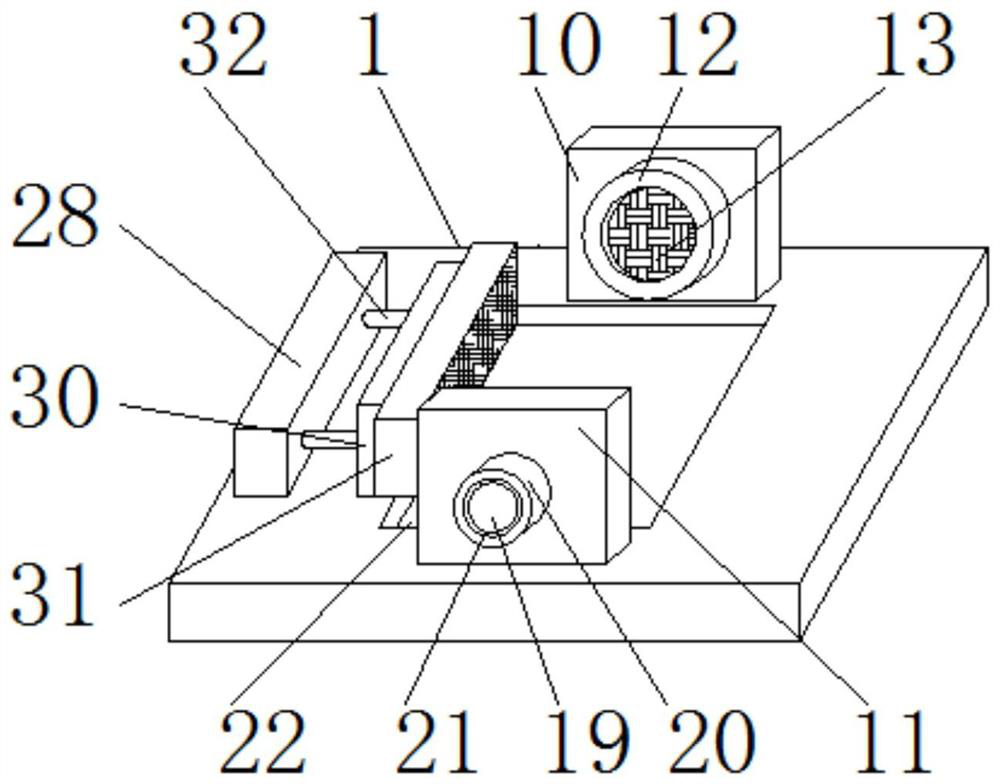

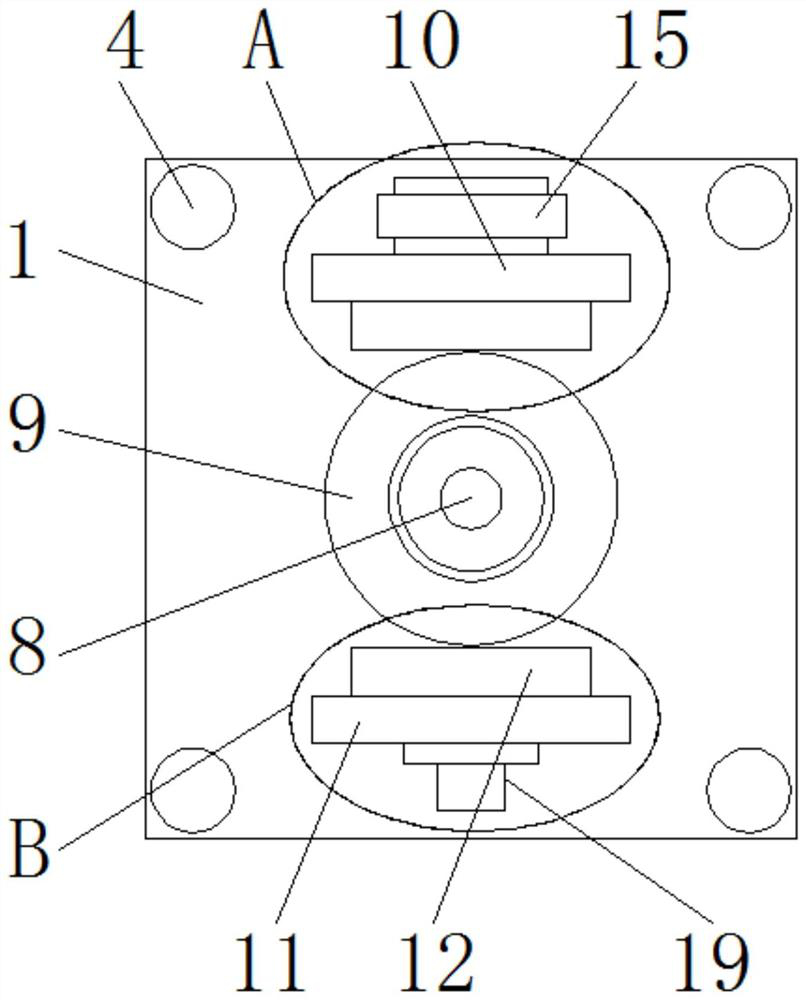

[0036] see Figure 1-7 , the present invention provides a kind of deburring equipment for aluminum alloy castings, comprising a table body 1, the lower surface of the table body 1 is vertically welded with a pillar 2 at the periphery of the periphery, and the lower end of the stage pillar 2 is fixedly sleeved with a foot 3, and the foot 3 It is made of plastic, and the upper surface of the table body 1 is vertically welded with struts 4 around the edges. The upper ends of the four sets of struts 4 are fixedly installed with the same set of load plates 5, and the middle position of the upper surface of the load plate 5 is fixedly installed. There is a motor 6, and the middle position of the bottom of the motor 6 is vertically movably connected with a rotating shaft 7, the load plate 5 is arranged in parallel above the table body 1, and the lower end of the rotating shaft 7 is vertically movable and installed between the middle positions of the upper and lower surfaces of the loa...

Embodiment 2

[0038] see Figure 1-6 and Figure 8 , the present invention provides a kind of deburring equipment for aluminum alloy castings, comprising a table body 1, the lower surface of the table body 1 is vertically welded with a pillar 2 at the periphery of the periphery, and the lower end of the stage pillar 2 is fixedly sleeved with a foot 3, and the foot 3 It is made of plastic, and the upper surface of the table body 1 is vertically welded with struts 4 around the edges. The upper ends of the four sets of struts 4 are fixedly installed with the same set of load plates 5, and the middle position of the upper surface of the load plate 5 is fixedly installed. There is a motor 6, and the middle position of the bottom of the motor 6 is vertically movably connected with a rotating shaft 7, the load plate 5 is arranged in parallel above the table body 1, and the lower end of the rotating shaft 7 is vertically movable and installed between the middle positions of the upper and lower surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com