High-power LED module

A LED module, high-power technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve problems such as uneven temperature distribution, lower LED quality, LED chip aging, etc., to achieve the effect of improving light reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

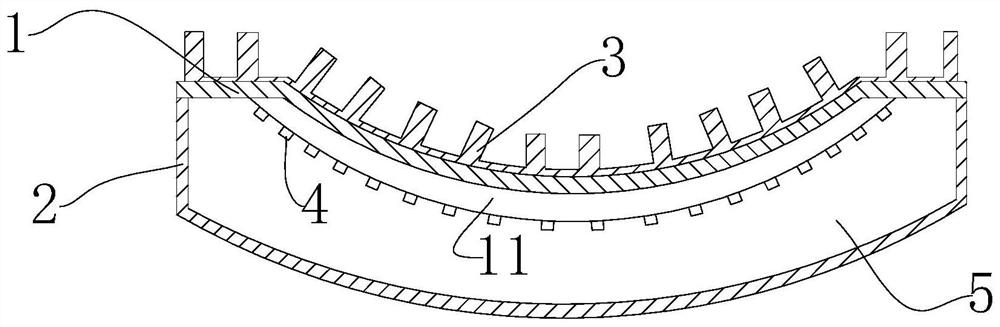

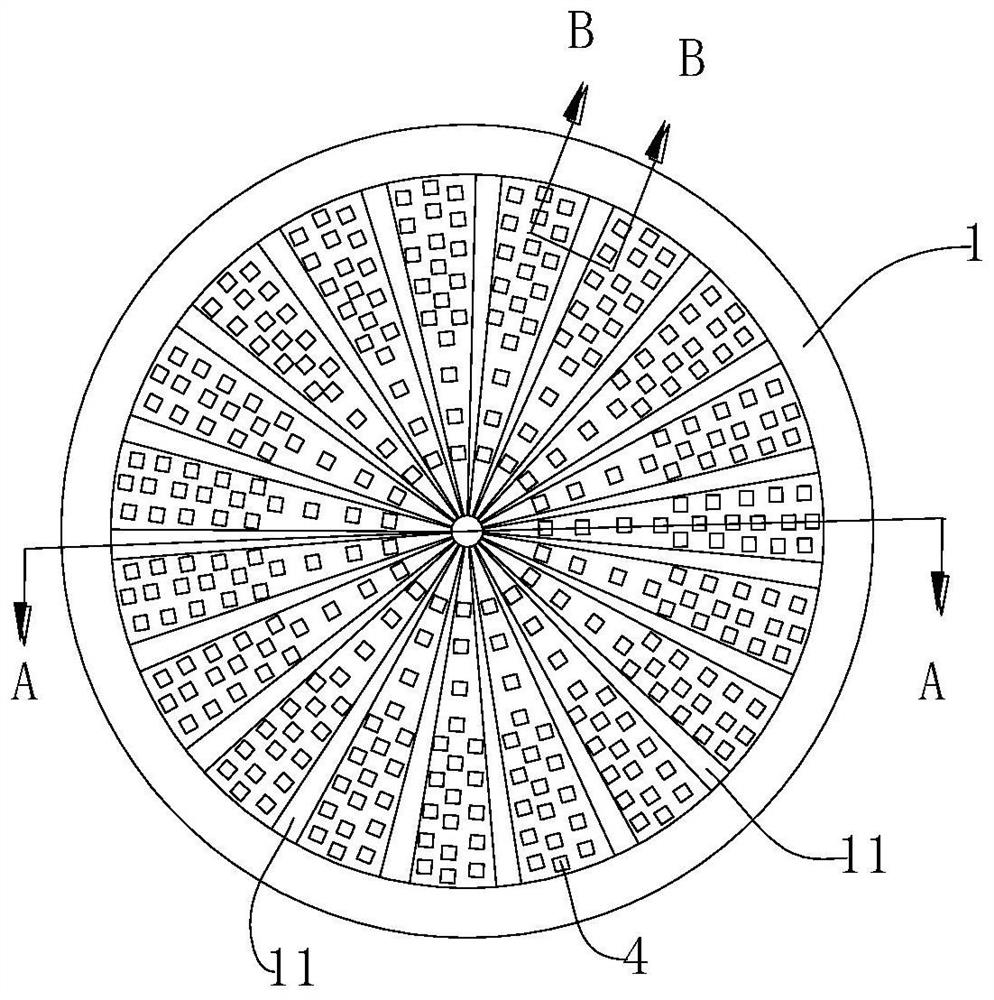

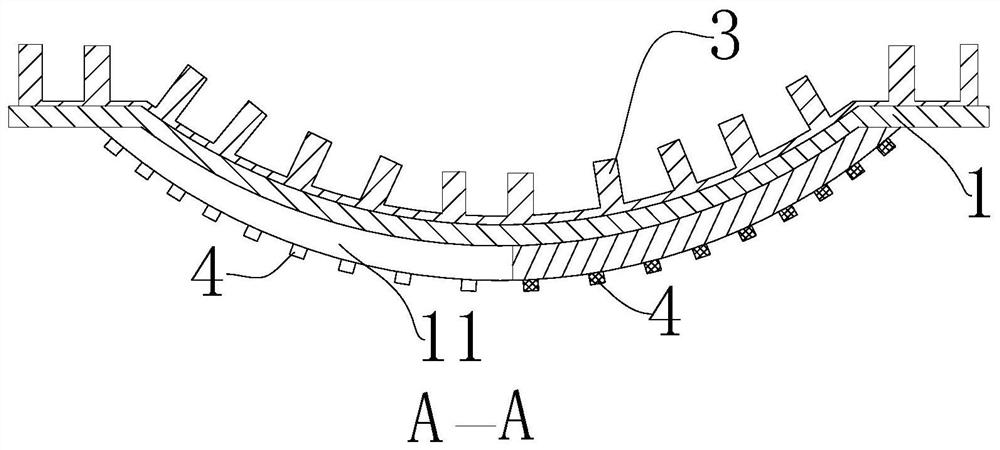

[0025] Such as Figure 1-2 As shown in a high-power LED module, a number of LED chips 4 are pasted on the front surface of a substrate 1 by silver glue. The farther the distance from the center of the substrate 1 is, the smaller the distance between the LED chips 4 is. The heat sink 3 is adhered to the back surface of the substrate 1 with an adhesive. The substrate 1 is made of copper to improve the heat dissipation capacity of the substrate 1. The base plate 1 is a spherical shell with flanges on the edges to facilitate the installation of the transparent cover 2. The center of the spherical shell is on the back side of the substrate 1, so that the front surface of the substrate 1 is the outer surface of the spherical shell, and the back of the substrate 1 is the inner surface of the spherical shell.

[0026] Such as image 3 , The transpar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com