Copper Plating Solution for Blind Via Filling for HDI Boards and Carriers

A technology of electroplating copper and blind holes, which is applied in the field of material electrochemistry, can solve the problems of unstable signal transmission, low reliability of electroplating, and short service life of bath solution, so as to reduce the generation of brightener by-products, reduce the impact, and improve electroplating The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The formula consists of the following:

[0057] Copper sulfate pentahydrate: 200g / L

[0058] Sulfuric acid 98%: 50g / L

[0060] Sodium lignosulfonate: 1mg / L

[0061] Sodium dodecyl sulfate: 300mg / L

[0062] N-Alkylphthalimide: 20mg / L

[0063] Deionized water: balance

[0064] Solution preparation process: Take 1L solution as an example, take 300ml of deionized water, add copper sulfate pentahydrate: 200g; sulfuric acid: 50g, copper chloride dihydrate: 0.114g, sodium lignosulfonate: 1mg; Sodium sulfonate: 300mg; N-alkylphthalimide: 20mg, stir to dissolve, and then add deionized water to the liquid level to 1L.

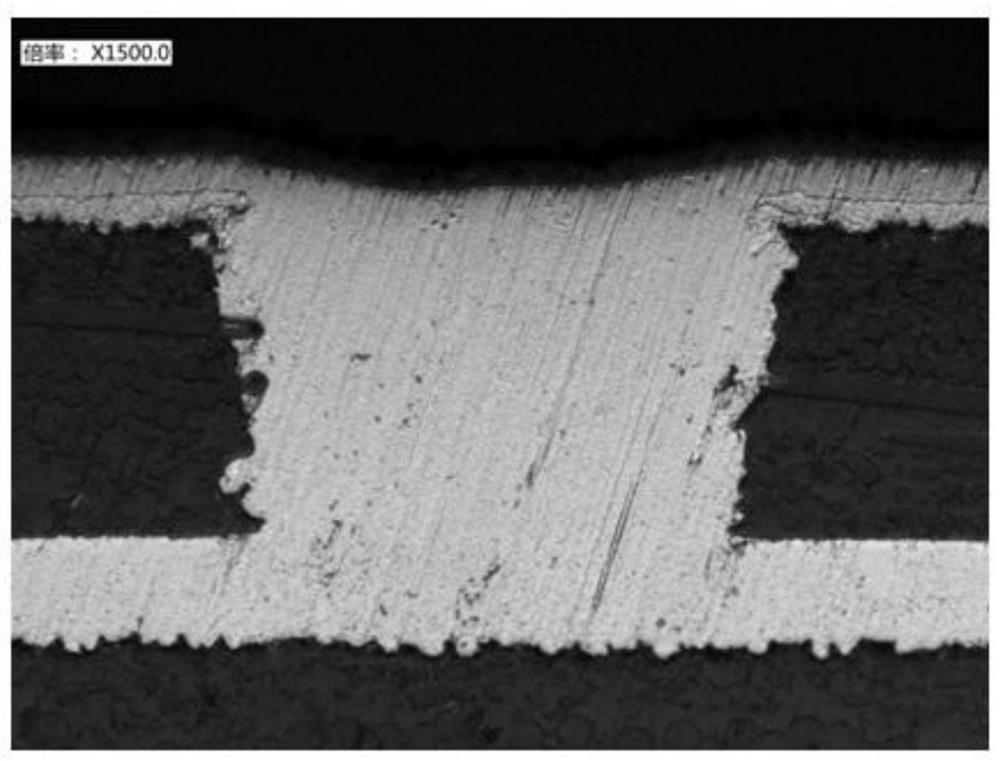

[0065] Process parameters for electroplating using the copper electroplating solution prepared in this example: spray: 5 min, temperature: 25±2° C., current density: 1.5 ASD, stirring rate: 5 TO / H, time: 60 min. After the preparation of the above electroplating bath solution is completed, it needs to be electrolyzed to 2AH / L be...

Embodiment 2

[0069] The formula consists of the following:

[0070] Copper sulfate pentahydrate: 180g / L

[0071] Sulfuric acid 98%: 50g / L

[0073] Sodium lignosulfonate: 1.5mg / L

[0074] Sodium dodecyl sulfate: 400mg / L

[0075] N-Alkylphthalimide: 20mg / L

[0076] N-propanolamine: 40mg / L

[0077] Deionized water: balance

[0078] Solution preparation process: Take 1L solution as an example, take 300mL of deionized water, add copper sulfate pentahydrate: 180g; sulfuric acid: 50g, copper chloride dihydrate: 0.114g, sodium lignosulfonate: 1.5mg; dodecane Sodium sulfonate: 400mg; N-alkylphthalimide: 20mg, n-propanolamine: 40mg, stir to dissolve, and then add deionized water to the liquid level to 1L.

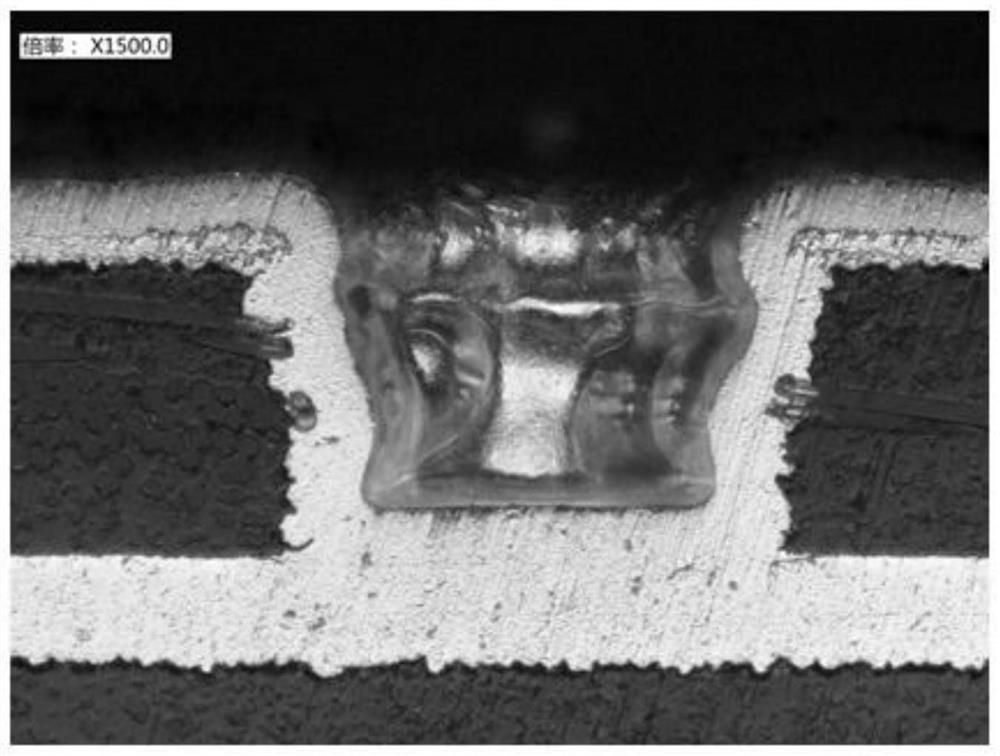

[0079] Process parameters for electroplating using the copper electroplating solution prepared in this example: spray: 5 min, temperature: 25±2° C., current density: 1.5 ASD, stirring rate: 6 TO / H, time: 60 min. After the preparation of the above electroplati...

Embodiment 3

[0083] The formula consists of the following:

[0084] Copper sulfate pentahydrate: 190g / L

[0085] Sulfuric acid 98%: 50g / L

[0086] Chloride ion: 60mg / L

[0087] Sodium 1-octanesulfonate: 2mg / L

[0088] Polyethyleneimine: 350mg / L

[0089] N-Alkylphthalimide: 20mg / L

[0090] Hexamethylenetetramine: 45mg / L

[0091] Deionized water: balance

[0092] Solution preparation process: Take 1L solution as an example, take 300mL of deionized water, add copper sulfate pentahydrate: 190g; sulfuric acid: 50g, copper chloride dihydrate: 0.137g, sodium 1-octanesulfonate: 2mg; polyethylene Imine: 350mg; N-alkylphthalimide: 20mg, hexamethylenetetramine: 45mg, stir to dissolve, and then add deionized water to the liquid level to 1L.

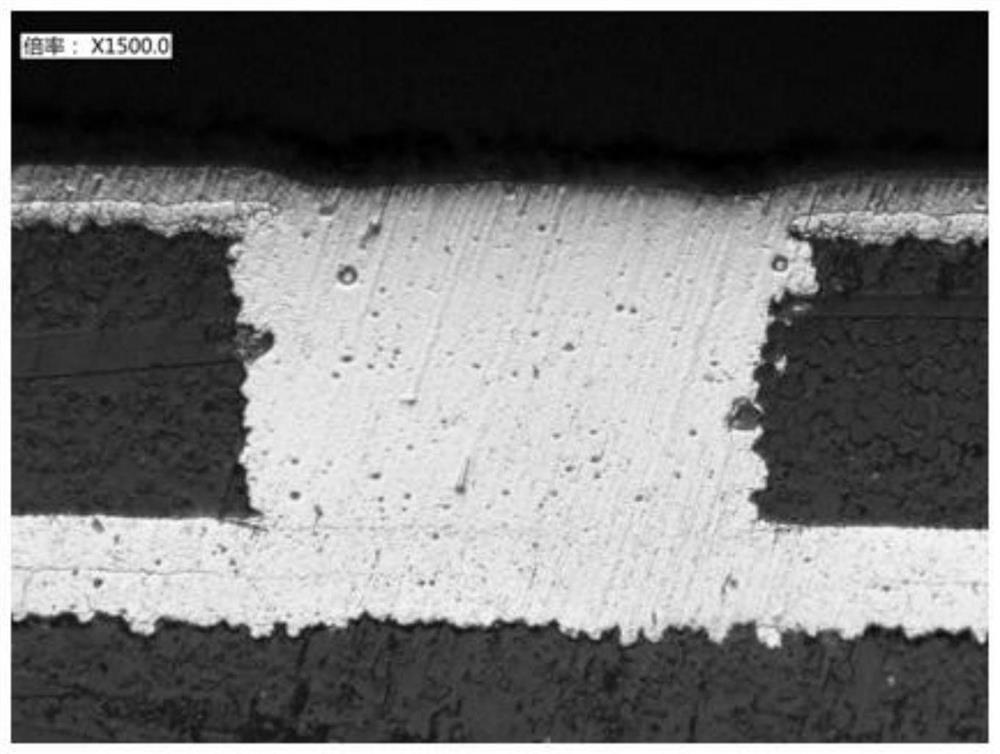

[0093] Process parameters for electroplating using the copper electroplating solution prepared in this example: spraying: 5min, temperature: 25±2°C, current density: 2ASD, stirring rate: 8TO / H, time: 50min. After the preparation of the above electroplatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com