Silica sol soybean protein adhesive for fiberboard production and preparation method thereof

A technology for soybean protein and soybean protein isolate, which is applied in the field of silica sol soybean protein adhesive and its preparation, can solve problems such as endangering physical and mental health, endangering physical health, polluting the environment, etc., achieving easy production control, solving environmental pollution, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

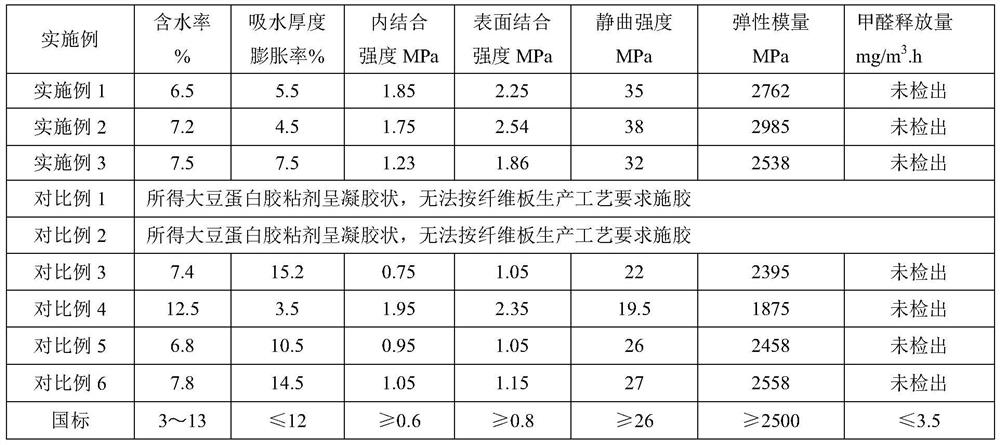

Embodiment 1

[0029] Add 0.05Kg of sodium tetraborate and 100Kg of water into the reaction vessel, stir to dissolve, then add 5Kg of soybean protein powder, stir and mix thoroughly, then add 2.5Kg of urea, stir and heat to 60°C for modification reaction for 60 minutes, stir The speed is 50rpm. After the reaction, cool the product to 30°C, add 5Kg of silica sol with a solid content of 30% and a pH value of 9 to the product, stir and mix well, then add 10Kg of polyvinyl alcohol aqueous solution with a concentration of 8%, and stir well That is to prepare the silica sol soybean protein adhesive for fiberboard production. The performance index of the tested soybean protein adhesive is shown in Table 1.

Embodiment 2

[0031] Add 0.05Kg of sodium tetraborate and 100Kg of water into the reaction vessel, stir to dissolve, then add 8Kg of soybean protein powder, stir and mix thoroughly, then add 3.5Kg of urea, stir and heat to 60°C for modification reaction for 60 minutes, stir The speed is 50rpm. After the reaction, cool the product to 30°C, add 8Kg of silica sol with a solid content of 20% and a pH value of 7 to the product, stir and mix well, then add 12Kg of polyvinyl alcohol aqueous solution with a concentration of 8%, and stir well That is to prepare the silica sol soybean protein adhesive for fiberboard production. The performance index of the tested soybean protein adhesive is shown in Table 1.

Embodiment 3

[0033] Add 0.03Kg of sodium tetraborate and 100Kg of water into the reaction vessel, stir to dissolve, then add 3.5Kg of soybean protein powder, stir and mix thoroughly, then add 1.5Kg of urea, stir and heat to 55°C for 40 minutes of modification reaction, The stirring speed was 60 rpm. After the reaction, cool the product to 25°C, add 5Kg of silica sol with a solid content of 20% and a pH value of 9 to the product, stir and mix well, then add 8Kg of polyvinyl alcohol aqueous solution with a concentration of 11%, and stir well That is to prepare the silica sol soybean protein adhesive for fiberboard production. The performance index of the tested soybean protein adhesive is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com