Forming production method for epoxy glass fiber reinforced plastic fiber pipe

A technology of epoxy glass fiber reinforced plastic and production method, which is applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems that the fiber filament is not easy to roll, the fiber filament layer is prone to loosening, and the production is monotonous, so as to reduce the folding volume. The effect of reducing the probability of winding phenomenon, reducing loose phenomenon and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

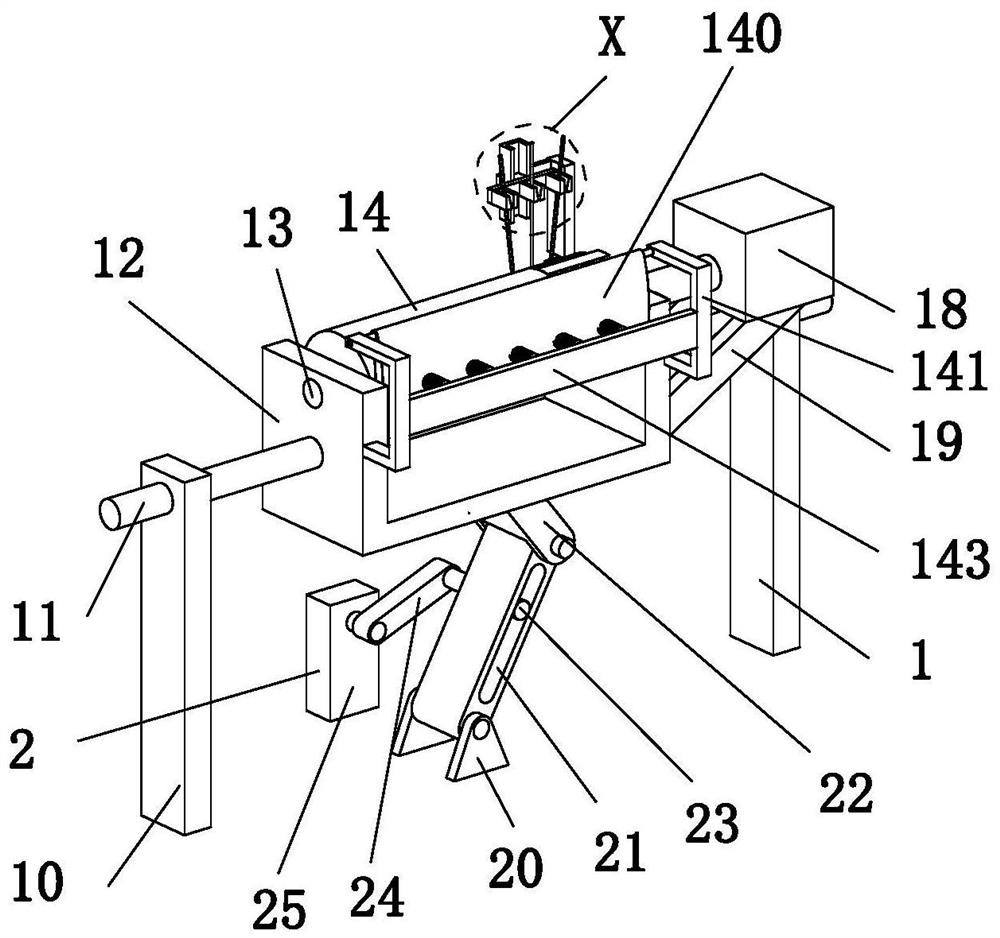

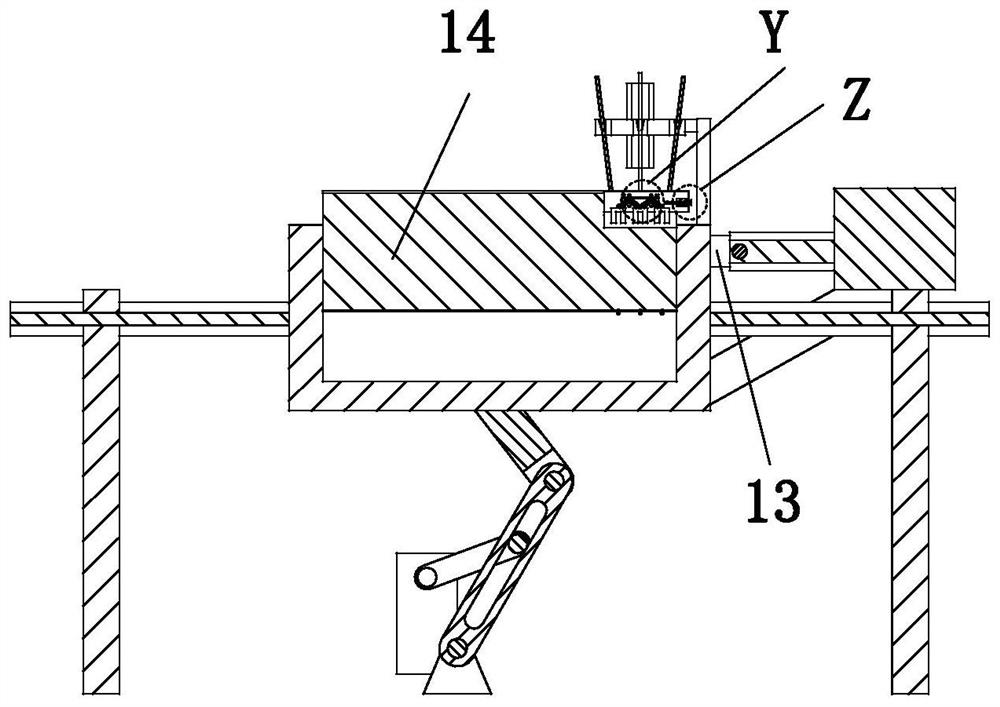

[0038] Such as Figure 1 to Figure 11 Shown, a kind of epoxy fiberglass fiber pipe molding production method, it has used a kind of epoxy fiberglass fiber pipe molding production device, this epoxy fiberglass fiber pipe molding production device includes winding mechanism 1 and running mechanism 2, adopts above-mentioned epoxy The specific production method of the glass fiber reinforced plastic tube forming production device is as follows:

[0039] S1. Preparing for installation before winding: Suspend the winding core 14 in the U-shaped block 12 manually and make the fixed shaft 13 cross the vertical plate 10 and the winding core 14, and the protrusion 16 and the rectangular groove cooperate with the winding core 14 Fix between the fixed shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com