Sheet material graining machine with gap adjusting mechanism

A gap adjustment and embossing machine technology, which is applied in the field of plate embossing machines, can solve the problems that the spacing cannot be adjusted, and cannot meet the processing requirements of different sizes of plates, etc., and achieve the effect of simple structure design and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

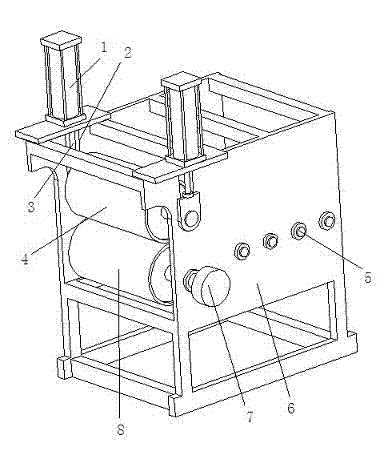

[0013] see figure 1 , a plate embossing machine with a gap adjustment mechanism, has a support 6, and the support 6 is provided with a passive roller 4 and a driving roller 8 arranged in a longitudinal direction.

[0014] The two ends of the passive roller 4 are placed in the square through holes 2 on both sides of the top of the support 6. The top of the support 6 is provided with two cylinders 1, and the telescopic rods 3 of the two cylinders 1 are connected with the two ends of the passive roller 4.

[0015] The driving roller 8 is connected to the motor 7, and the driving roller 8 and the passive roller 4 are provided with a textured protrusion structure (same as the texture of the board to be processed, such as patterns, etc.).

[0016] At the same time, several drive rollers 5 arranged horizontally are also arranged on the bracket 6 .

[0017] The above content is only an example and description of the structure of the present invention. Those skilled in the art make va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com