High-toughness garbage can and preparation method thereof

A trash can, high toughness technology, applied in paper recycling, plastic recycling, recycling technology and other directions, can solve the problems of aging and degradation of polypropylene materials, deterioration of mechanical properties, shortened service life of polypropylene materials, affecting the use of trash cans and other problems , to achieve the effect of improving the mixing effect of raw materials, increasing the range of motion, and improving the drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

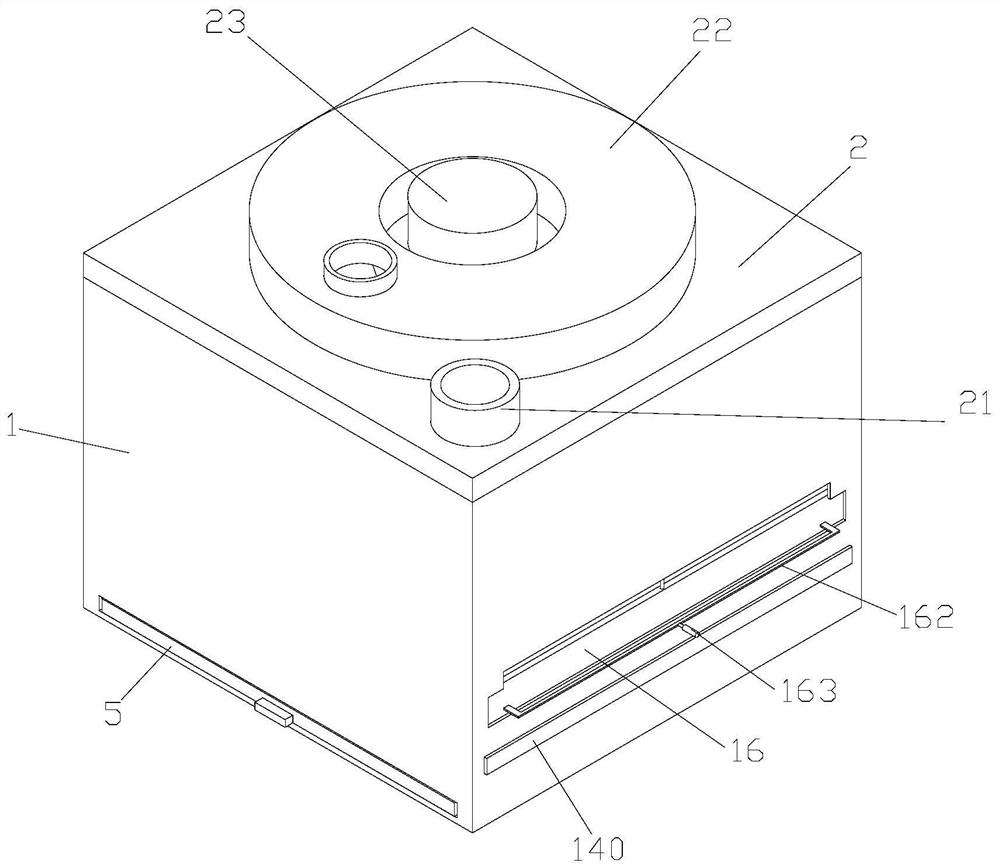

Image

Examples

Embodiment 1

[0041] A high-toughness trash can, in terms of parts by mass, the formula of the plastic bucket includes: 50-60 parts of polypropylene, 15 parts of modified montmorillonite, 2 parts of ultraviolet absorber, 3 parts of filler, 1 part of lubricant and 0.5 part of flame retardant; the preparation method of the modified montmorillonite is: 1) adding cyanuric chloride to acetone, under ice-water bath conditions, stirring until cyanuric chloride is completely dissolved; 2) p-aminobenzene Sodium sulfonate is dissolved in deionized water to form a solution, and added dropwise to the solution of step 1), the pH of the solution is controlled at 5 during the dropwise addition, and after the dropwise addition, continue to stir for 2h; 3) raise the temperature of the system to Add tetramethylpiperidinamine to the above reaction system at 45°C, adjust the pH of the reaction system to 6.5, continue to stir for 5 hours, then cool to room temperature, centrifuge the obtained product and wash it...

Embodiment 2

[0056] A garbage can, in parts by mass, said plastic bucket formula comprising: 60 parts of polypropylene, 20 parts of modified montmorillonite, 5 parts of ultraviolet absorber, 5 parts of filler, 3 parts of lubricant and 3 parts of flame retardant Part; the preparation method of described modified montmorillonite is: 1) cyanuric chloride is joined in acetone, under the condition of ice-water bath, stir until cyanuric chloride dissolves completely; 2) sodium p-aminobenzenesulfonate is dissolved Make a solution in deionized water, and add it dropwise to the solution in step 1), and control the pH of the solution at 6 during the dropping process, and continue stirring for 2 to 4 hours after the dropping; 3) Raise the temperature of the system to 60°C , then add tetramethylpiperidinamine into the above reaction system, adjust the pH of the reaction system at 67.5, continue to stir for 5-6 hours, then cool to room temperature, centrifuge the obtained product and wash it with ethano...

Embodiment 3

[0058]A trash can, in parts by mass, the formula of the plastic bucket includes: 55 parts of polypropylene, 18 parts of modified montmorillonite, 4 parts of ultraviolet absorber, 4 parts of filler, 2 parts of lubricant and flame retardant 02 Part; the preparation method of described modified montmorillonite is: 1) cyanuric chloride is joined in acetone, under the condition of ice-water bath, stir until cyanuric chloride dissolves completely; 2) sodium p-aminobenzenesulfonate is dissolved Make a solution in deionized water, and add dropwise to the solution in step 1), the pH of the solution is controlled at 5 during the dropwise addition, and after the dropwise addition, continue to stir for 3 hours; 3) Raise the temperature of the system to 50°C, and then Add tetramethylpiperidinamine to the above reaction system, adjust the pH of the reaction system at 7, continue to stir for 5.5 h, then cool to room temperature, centrifuge the obtained product and wash it with ethanol, and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com