Rotary table for positioning battery compartment top cover and processing device with the same

A technology of processing device and rotary table, applied in positioning device, feeding device, storage device, etc., can solve the problems of inconvenient positioning, affecting punching quality, time-consuming and laborious, etc., to reduce tensile deformation, improve production quality, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

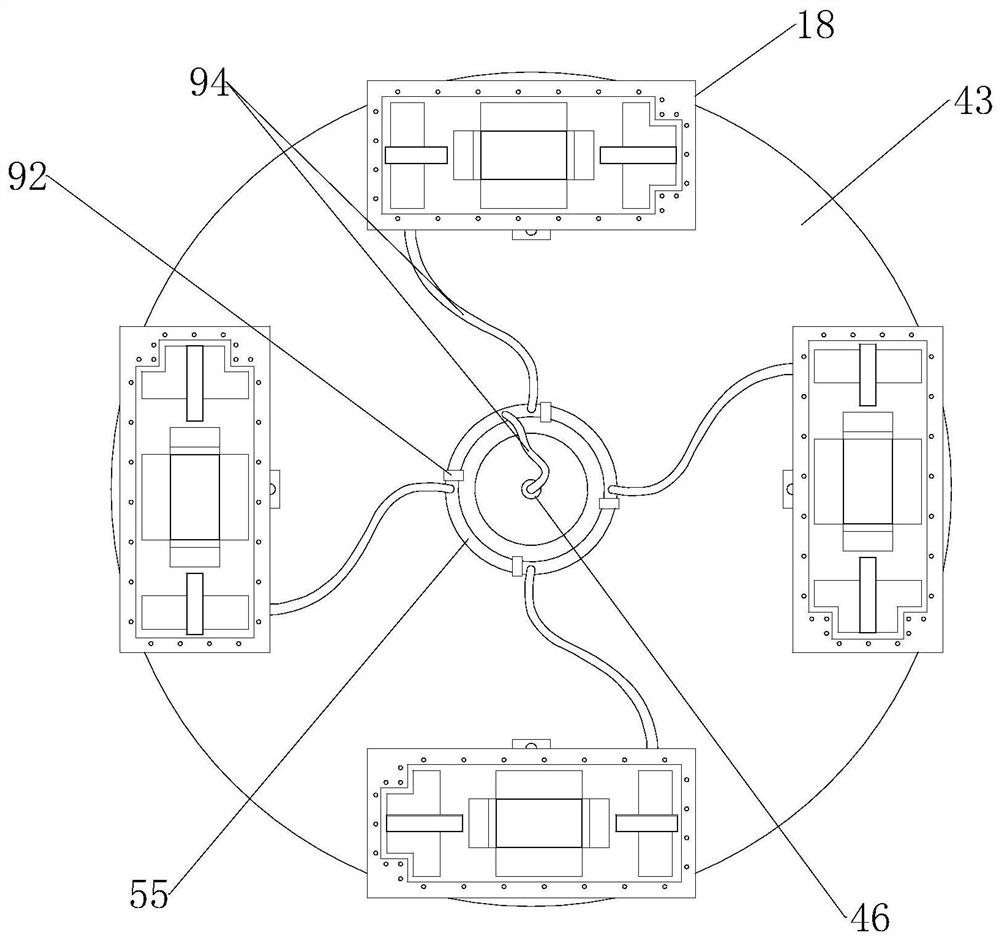

[0091] Such as Figure 2 to Figure 15 As shown, the turntable for positioning the top cover of the battery compartment includes a turntable support base 42 on which a turntable 43 is rotated, and a turntable for driving the turntable 43 to rotate is also arranged on the turntable support base 42 driving device;

[0092] The rotary table support base 42 has a hollow rotary support gas circulation chamber 44, the rotary table support base 42 is provided with a support base air inlet 45 communicating with the rotary support gas circulation cavity 44, and the rotary table support base 42 is connected with a rotary support. The pneumatic universal joint 46 connected to the gas flow chamber 44; the rotary table 43 is provided with several positioning stations arranged in a ring on the rotary table 43, and the lower mold unit driving device is installed on the positioning station. The output end of the mold unit driving device is connected with the lower mold unit;

[0093] The low...

Embodiment 2

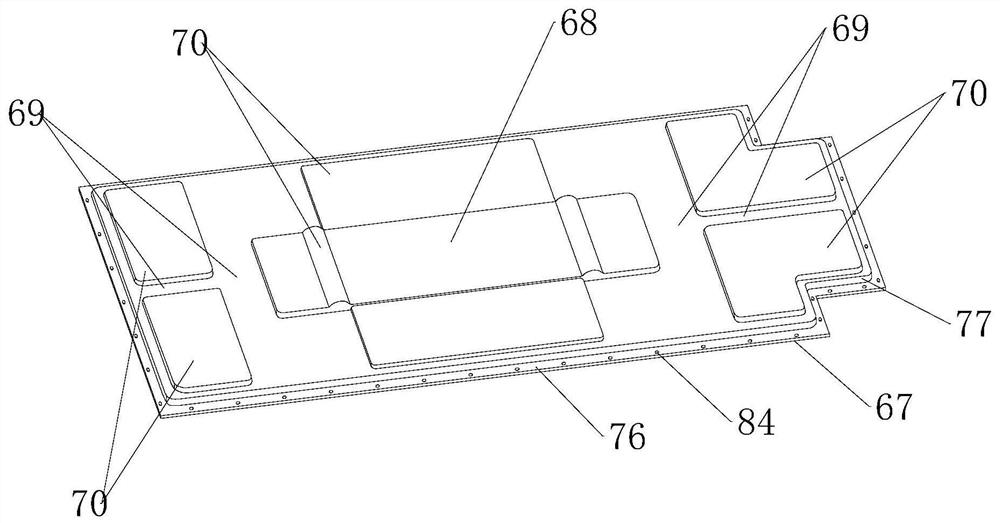

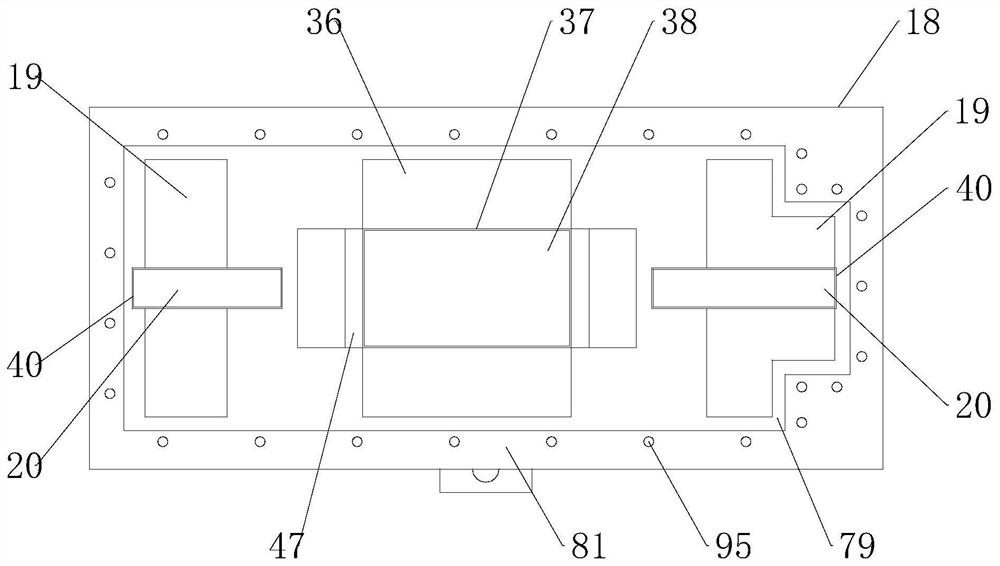

[0102] This embodiment makes the following further limitations on the basis of Embodiment 1: the lower mold middle groove 36 has two left and right symmetrically arranged and spaced middle concave sections 47, and the lower mold support seat 18 is located between the two middle concave sections 47. The area between also offers the gap 37 in the middle part of the lower mold, the gap 37 in the middle part of the lower mold is movably provided with a top piece 38 in the middle part of the lower mold, and the support seat 18 of the lower mold is also provided with a top piece 38 for driving the middle part of the lower mold. The upper part driving device 39 in the middle of the lower mold that moves up and down;

[0103] The lower mold end groove assembly includes at least two lower mold end grooves 19, and the lower mold support seat 18 is also provided with a lower mold end relief gap 40 in the area between two adjacent lower mold end grooves 19. , the gap 40 at the end of the ...

Embodiment 3

[0110] A processing device for the top cover of a battery compartment, comprising an upper mold unit and a rotary table for positioning the top cover of the battery compartment as described in any one of embodiments 1 to 2, the upper mold unit is facing several of the lower mold units Any lower module unit of ;

[0111] The upper mold unit includes an upper mold support seat 1, and the bottom end of the upper mold support seat 1 is provided with an upper mold middle part protrusion 21 matching the lower mold middle part groove 36 in the aforementioned lower mold unit and two located on the upper mold The end protrusion assembly on both sides of the middle protrusion 21, the end protrusion assembly is matched with the lower die end groove assembly in the aforementioned lower die unit;

[0112] The middle protrusion 21 of the upper mold has two middle protrusion segments 22 matching the middle concave segment 47, and the area between the two middle protrusion segments 22 is a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com