Test system for testing the shear strength of metal and glass adhesives

A shear strength, test system technology, applied in the direction of using a stable shear force to test material strength, strength characteristics, measuring devices, etc., can solve problems such as unreported, non-pure shear damage, shaking, etc. Injuring the operator, the overall structure is simple, and the positioning structure is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

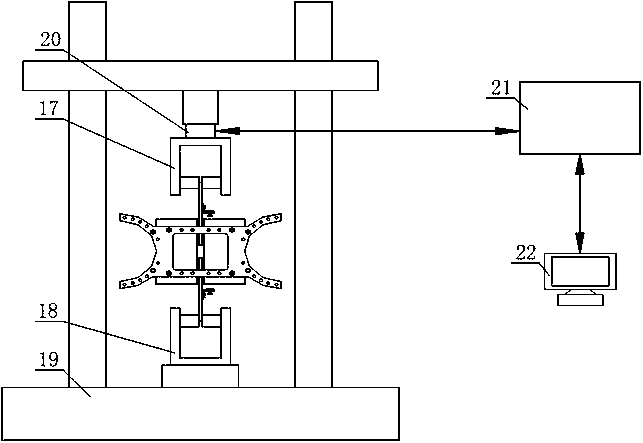

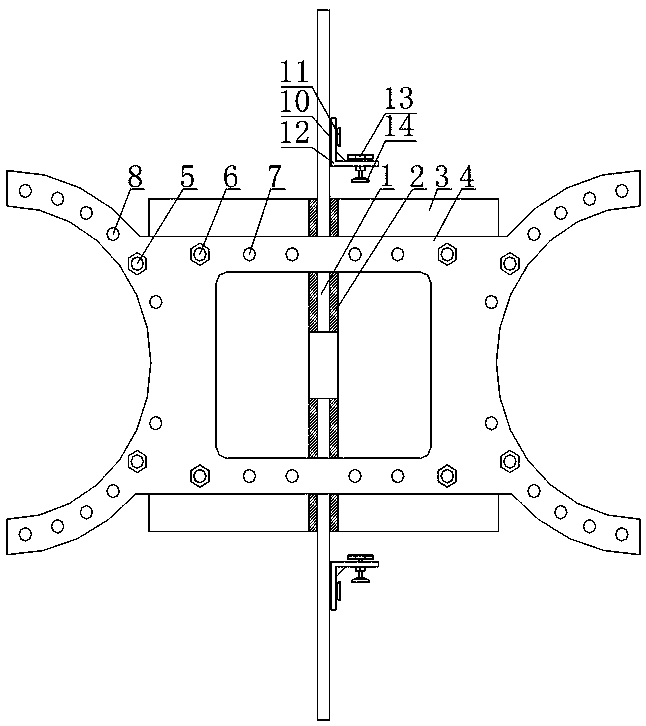

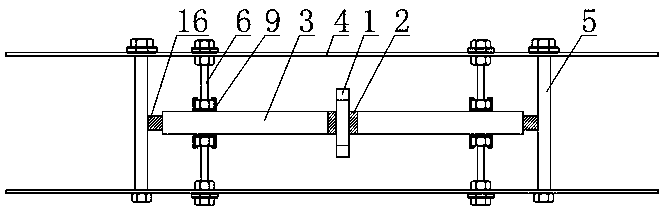

[0033] like Figure 1 ~ Figure 4As shown, the test system for testing the shear strength of metal and glass viscose includes a metal plate 1, a glass panel 3, a splint 4 and a universal testing machine 19, wherein the universal testing machine 19 is provided with an upper clamping system 17 and a lower clamping system. System 18 , the lower clamping system 18 is located directly below the upper clamping system 17 . In this embodiment, the number of metal plates 1 and clamping plates 4 is two, and the two metal plates 1 are all vertically arranged and both are clamped and fixed by the upper clamping system 17 and the lower clamping system 18 respectively. After the system 17 and the lower clamping system 18 clamp and fix the two metal plates 1, the fixed metal plate 1 clamped by the upper clamping system 17 is located directly above the metal plate 1 clamped by the lower clamping system 18. The two metal plates 1 are arranged coaxially, and there is a gap between the end of th...

Embodiment 2

[0036] This embodiment makes the following further limitations on the basis of Embodiment 1: In order to facilitate intelligent control, the test system for testing the shear strength of metal and glass viscose in this embodiment also includes an actuator 20, a main control box 21 and A computer system 22, wherein the actuator 20 is connected to the upper clamping system 17, and the main control box 21 is respectively connected to the actuator 20 and the computer system 22 through two data lines. The system of this embodiment is used to control the applied force and carry out corresponding records when testing the shear strength of metal and glass glue, all carried out in the computer system 22, and the specific process is: the computer system 22 sends a control signal, and by The main control box 21 performs signal conversion, and transmits the loading signal to the actuator 20 connected with the upper clamping system 17 of the universal testing machine 19. During the test, th...

Embodiment 3

[0038] This embodiment makes the following further limitations on the basis of Embodiment 1 or Embodiment 2: the left and right ends of the splint 4 in this embodiment are provided with arc-shaped positioning plates, and the arc-shaped positioning plate at the left end of the splint 4 opens to the left , the arc positioning plate at the right end of the clamping plate 4 opens to the right, the arc positioning plate internal diameter is greater than the height of the clamping plate 4, and the arc positioning plate is provided with a plurality of connecting holes 8 running through its front and rear end faces along its curved surface. The splint connection assembly 5 of this embodiment includes bolts and nuts. The splint connection assembly 5 passes through the connection holes 8 of the two splints 4 through the bolts and sets nuts on the bolts to realize the fixed connection of the two splints 4 . In order to ensure the structural strength of this embodiment, the arc-shaped posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com