Dismounting device and method for seamless steel tube cold-rolling expansion-stop plug

A technology for seamless steel pipes and dismantling devices, which is applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of high consumption of cemented carbide or ceramic tools, occupational hazards easily caused by operators, cutting speed and Low cutting volume and other issues, to achieve the effect of easy processing and preparation, compact structure and smooth process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

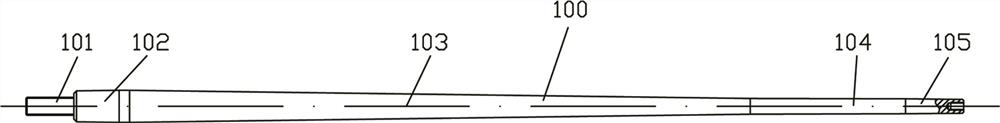

[0109] KPW-50 seamless steel pipe high-speed cold rolling mill, the diameter of the finished pipe is 25mm, the wall thickness is 2mm, and the stagflation head made of duplex stainless steel is non-destructively disassembled:

[0110] Adopt the high-temperature hot state axial positive pressure disassembly device, implement the device and process method provided by the present invention, and proceed according to the set process method, from disassembly preparation→installation and positioning of the station on the head→steam heating→disassembly operation→offline cleaning, etc. It consists of five processes. which is:

[0111] 1) Disassembly preparation: tooling preparation, steam source pipeline preparation, plug cleaning, etc.

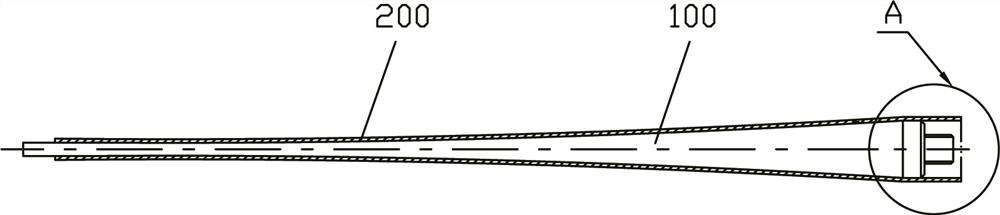

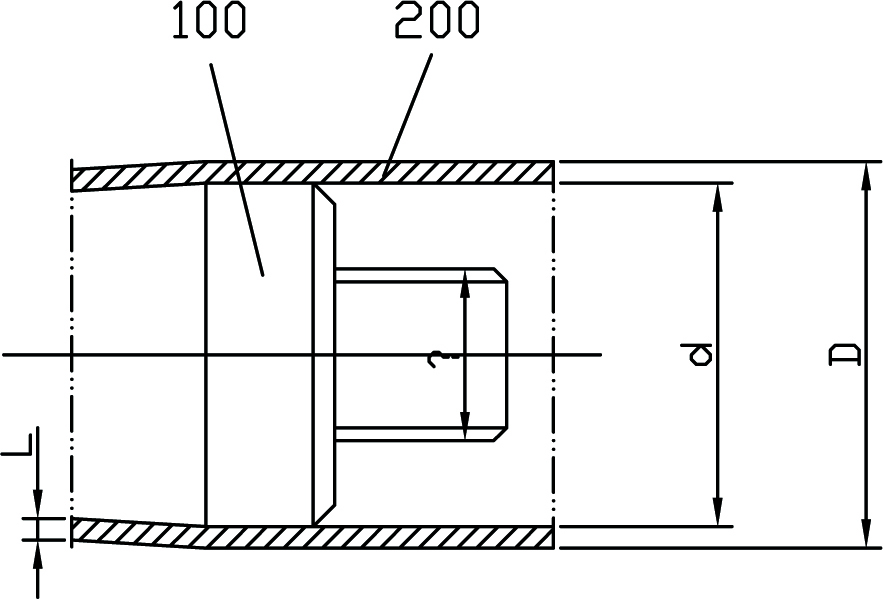

[0112] 2) Installation and positioning of the station on the head: firstly, the cut seamless steel pipe together with the stagflation and incarcerated small-diameter section of the cold-rolled head will pass through the rear end cover of the heating s...

Embodiment ( 2

[0117] LG-110H seamless steel pipe cold rolling mill, the diameter of the finished pipe is 110mm, the wall thickness is 8mm, and the stagflation head made of nickel-based alloy stainless steel is non-destructively disassembled:

[0118] Adopt the high-temperature hot state axial positive pressure disassembly device, implement the device and process method provided by the present invention, and proceed according to the set process method, from disassembly preparation→installation and positioning of the station on the head→steam heating→disassembly operation→offline cleaning, etc. It consists of five processes. which is:

[0119] 1) Disassembly preparation: tooling preparation, steam source pipeline preparation, plug cleaning, etc.

[0120] 2) Installation and positioning of the station on the head: firstly, the cut seamless steel pipe together with the stagflation and incarcerated small-diameter section of the cold-rolled head will pass through the rear end cover of the heatin...

Embodiment ( 3

[0125] LG-110H seamless steel pipe cold rolling mill, the diameter of the finished pipe is 76mm, the wall thickness is 4.5mm, and the grade is NS3105 (that is, the U.S. grade UNS N06690). Non-destructive disassembly of stagflation plugs for nuclear power pipes:

[0126] Adopt the high-temperature hot state axial positive pressure disassembly device, implement the device and process method provided by the present invention, and proceed according to the set process method, from disassembly preparation→installation and positioning of the station on the head→steam heating→disassembly operation→offline cleaning, etc. It consists of five processes. which is:

[0127] 1) Disassembly preparation: tooling preparation, steam source pipeline preparation, plug cleaning, etc.

[0128] 2) Installation and positioning of the station on the head: firstly, the cut seamless steel pipe together with the stagflation and incarcerated small-diameter section of the cold-rolled head will pass throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com