Glutamic acid production strain and preparation method and application thereof

A technology for the production of bacterial strains, Corynebacterium glutamicum, applied in the field of bioengineering, can solve problems such as gaps, and achieve the effect of promoting mutual penetration healing and strong glutamate dehydrogenase activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of glutamic acid high-yielding bacterial strain FM19-007 comprises the following steps:

[0038] (1) Preparation of protoplasts: Pretreat the seed liquid of Corynebacterium glutamicum A (preservation number CGMCC NO.1.10760) and Corynebacterium glutamicum B (preservation number CGMCC NO. 1.1735) with 1U / mL penicillin for 4 hours After that, add 1U / mL lysozyme to the seed liquid, and act at 34 °C for 12h, and add wheat germ agglutinin to the seed liquid at the fifth hour after adding lysozyme, and the amount of wheat germ agglutinin added is 0.1 g / L, that is, the amount of wheat germ agglutinin per liter of seed solution is 0.1g to obtain a protoplast suspension;

[0039] (2) Protoplast fusion: take 1 mL each of the protoplast suspensions of Corynebacterium glutamicum A (preservation number CGMCC NO. 1.10760) and Corynebacterium glutamicum B (preservation number CGMCC NO. 1.1735) in step (1) and mix , centrifuged for 15 min (10 000 × g), discarded the s...

Embodiment 2

[0047] Utilize the FM19-007 bacterial strain among the embodiment 1, ferment and produce glutamic acid, the steps are as follows:

[0048] (1) Preparation of fermentation medium: glucose: 40g / L, KH2PO4: 3g / L, MgSO4: 1g / L, FeSO4: 0.02g / L, MnSO4: 0.02g / L, soybean oligopeptide 50-100ppm, biotin 90-120ppm, vitamin B1 10-50ppm;

[0049] (2) Inoculation: Inoculate the above-mentioned FM19-007 strain with a cell concentration of 1×10 8 Individual / mL or more, the inoculum volume is 1%;

[0050] (3) Fermentation: pH 7.3±0.05, temperature 33-38.5°C, time 34-36 hours, after the 30th hour of fermentation, add scopolamine at a concentration of 5ppm, 5 μL of scopolamine per liter of fermentation broth;

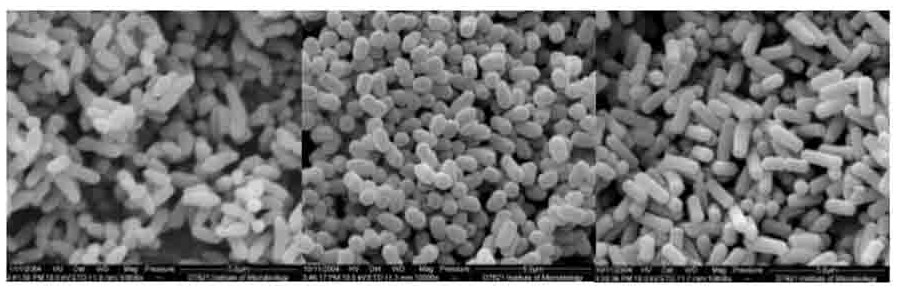

[0051] (4) Observation of obvious morphological changes in the fermentation process of the bacteria and at the same time changes in cell membrane permeability (forming cell leakage), such as figure 2 , image 3 shown;

[0052] (5) To measure the acid production rate of the fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com