A kind of iron-cobalt bimetallic selenide nanomaterial, its preparation method and lithium ion battery

A technology of lithium-ion batteries and nanomaterials, applied in iron-cobalt double metal selenide nanomaterials, its preparation method and the field of lithium-ion batteries, can solve the problems of complex process, poor product purity and crystallinity, and achieve simplified operation and improved crystallization The Effects of Sex and Purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides an iron-cobalt double metal selenide Fe 2 CoSe 4 Preparation methods of nanomaterials, including:

[0031] Iron acetylacetonate, cobalt acetylacetonate and dibenzyldiselenide are heated in a solvent to form Fe 2 CoSe 4 nanomaterials.

[0032] The present invention adopts specific precursor source---iron acetylacetonate [Fe(acac) 3 ], cobalt acetylacetonate [Co(acac) 2 ] and dibenzyldiselenide [(PhCH 2 ) 2 Se 2 ], react in a solvent system, can directly synthesize Fe in one step 2 CoSe 4 nanomaterials, and can effectively improve the Fe 2 CoSe 4 Nanomaterial crystallinity and purity. According to the research of the applicant, when using other conventional iron sources, cobalt sources or selenium sources, the one-step reaction rule of the present application cannot synthesize Fe 2 CoSe 4 nanomaterials. In the present invention, there is no special limitation on the sources of the iron acetylacetonate, cobalt acetylacetonate and diben...

Embodiment 1

[0049] 1.1 Preparation

[0050] Take 0.1mmol (35.3mg) iron acetylacetonate, 0.05mmol (12.8mg) cobalt acetylacetonate, 0.1mmol (34.0mg) dibenzyldiselenide and 5.0mL oleylamine solvent into a 100mL three-necked flask, and set up a reflux device. Under the conditions of argon atmosphere (atmospheric pressure in the flask) and magnetic stirring (rate 350rpm), the device was heated to 135°C at a constant speed (rate 10°C / min) and kept for 20min. Then continue to heat up to 280°C at 10°C / min and keep warm for 40min. Then naturally cool to room temperature, wash the precipitate in the there-necked flask several times with n-hexane and ethanol solution, then centrifuge and vacuum dry to obtain Fe 2 CoSe 4 nanomaterials.

[0051] 1.2 Characterization and testing

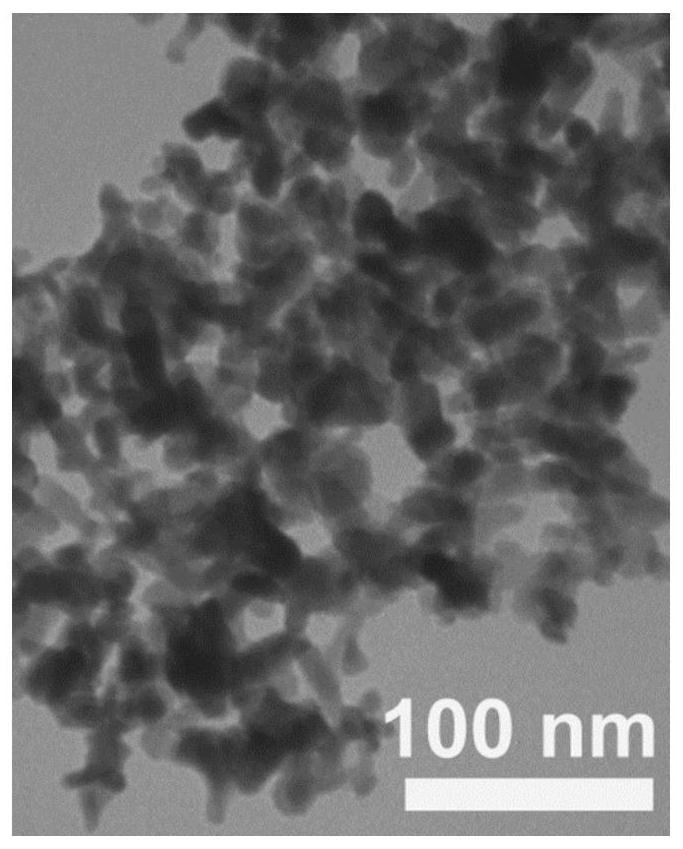

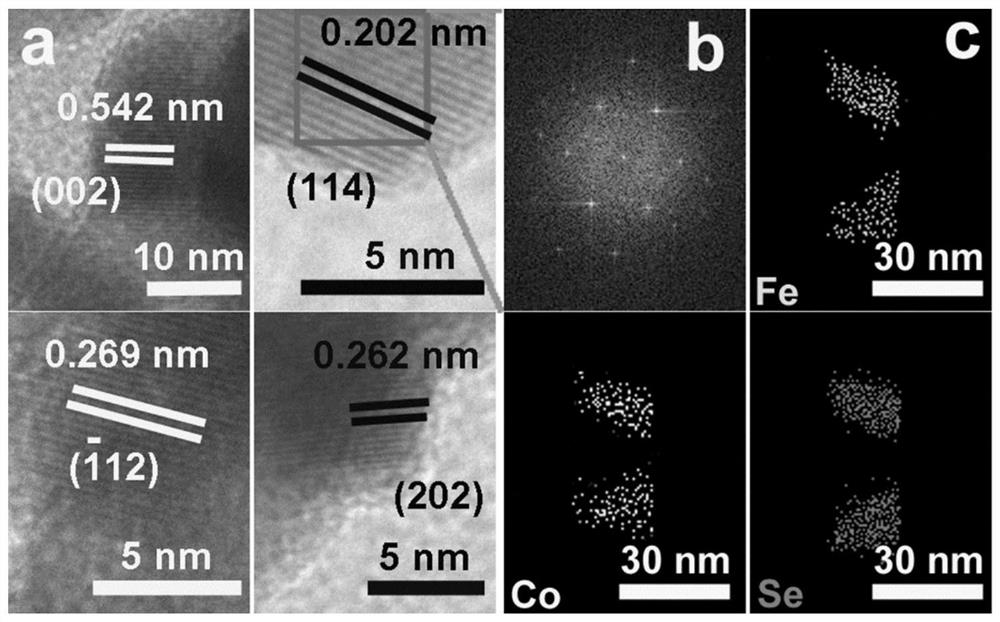

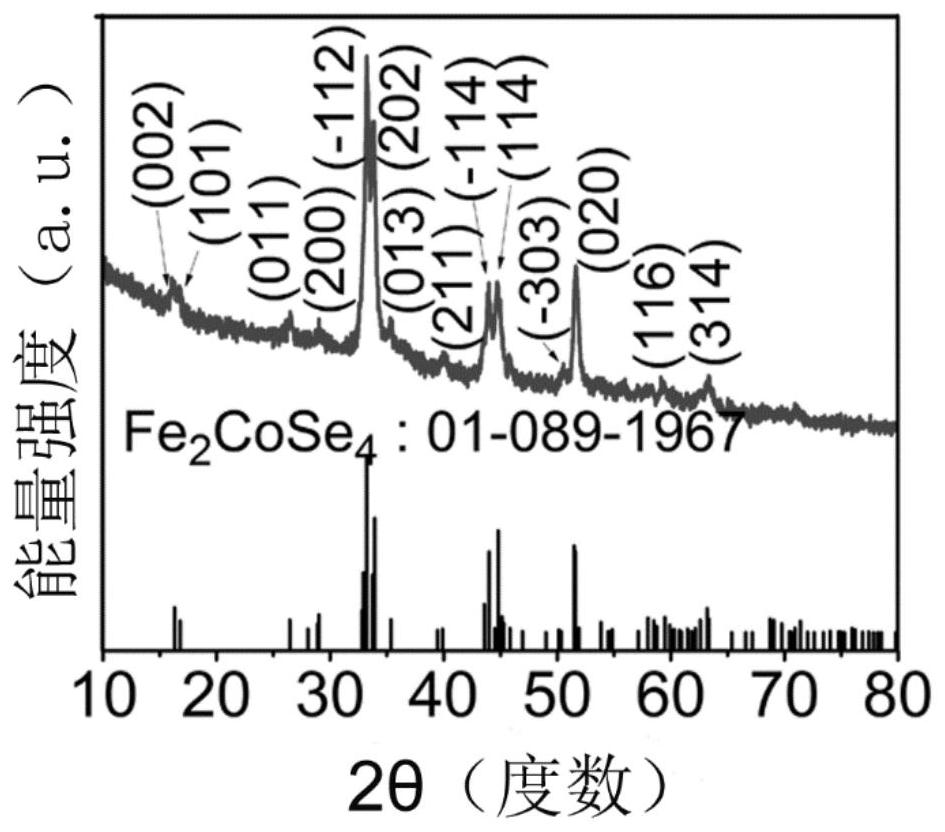

[0052] (1) The resulting product is tested by transmission electron microscope, and the results are as follows: figure 1 as shown, figure 1 It is a transmission electron microscope (TEM) test chart of the product obtain...

Embodiment 2

[0071] 1.1 Preparation

[0072] Take 0.1mmol (35.3mg) iron acetylacetonate, 0.05mmol (12.8mg) cobalt acetylacetonate, 0.1mmol (34.0mg) dibenzyldiselenide and 10.0mL oleylamine solvent into a 100mL three-necked flask, and set up a reflux device. Under the conditions of argon atmosphere (atmospheric pressure in the flask) and magnetic stirring (speed 450rpm), the device was heated to 120°C at a constant speed (rate 5°C / min) and kept for 25min. Then continue to heat up to 270°C at 5°C / min and keep warm for 60min. Then naturally cool to room temperature, wash the precipitate in the there-necked flask several times with n-hexane and ethanol solution, then centrifuge and vacuum dry to obtain Fe 2 CoSe 4 nanomaterials.

[0073] 1.2 Characterization and testing

[0074] Various characterizations were carried out according to the characterization test method in Example 1, and the results showed that the obtained product was a nanosheet material with a relatively uniform shape and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com