An injection mold for one-time molding of lightweight composite automobile inner door panels

A technology for injection molds and inner door panels, applied in the direction of coating, etc., can solve the problems of high processing costs and mold costs, low process efficiency, and restrictions on the development and application of composite automobile inner door panels, so as to improve processing efficiency and reduce processing costs and molds cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

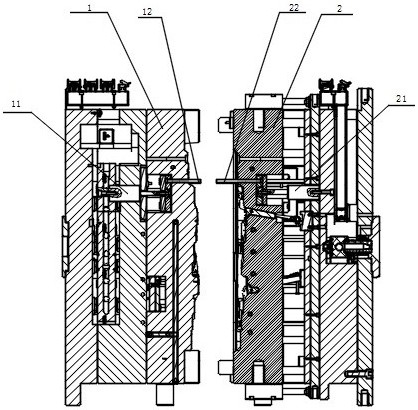

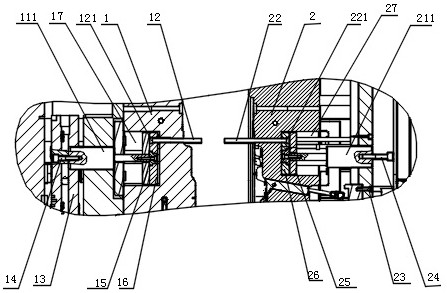

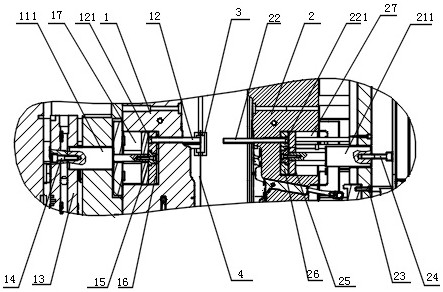

[0026] Example: such as Figure 1-8 As shown, an injection mold for one-time molding of lightweight composite automobile inner door panels is provided with a set of hydraulic clamping mechanisms between the fixed mold 1 and the movable mold 2 of the injection mold. The fixed mold hydraulic system 11 and the fixed mold hydraulic ejector pin 12 and the movable mold hydraulic system 21 and the movable mold hydraulic ejector pin 22 arranged on the movable mold 2.

[0027] The fixed mold hydraulic system 11 includes a fixed mold oil cylinder 111 arranged on the fixed mold 1, the fixed mold 1 is provided with a fixed mold oil cylinder fixing plate 13, and the fixed mold oil cylinder 111 is fixed on the fixed mold oil cylinder fixing plate 13 by the fixed mold oil cylinder fixing screw 14 , the piston rod of the fixed mold oil cylinder 111 is connected with the fixed mold ejector backing plate 15 and the fixed mold ejector fixing plate 16 by screws, the fixed mold 1 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com