One-time forming process of rotor milling groove of rasping machine

A forming process and rotor milling technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as low production efficiency, complex results, and slit size errors, so as to improve service life, improve processing efficiency and quality , to ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

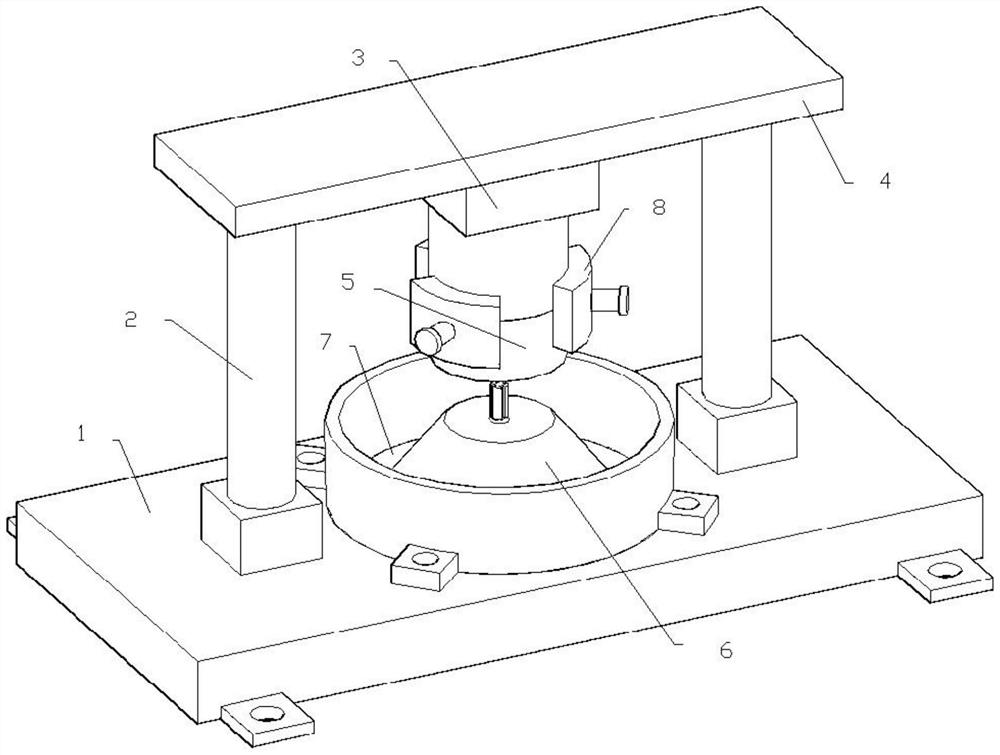

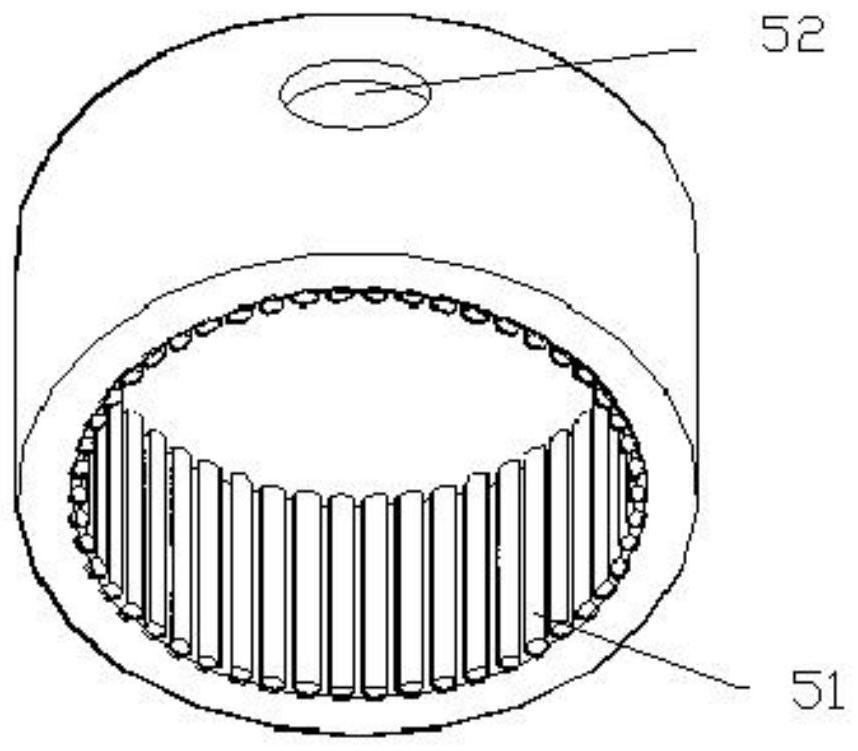

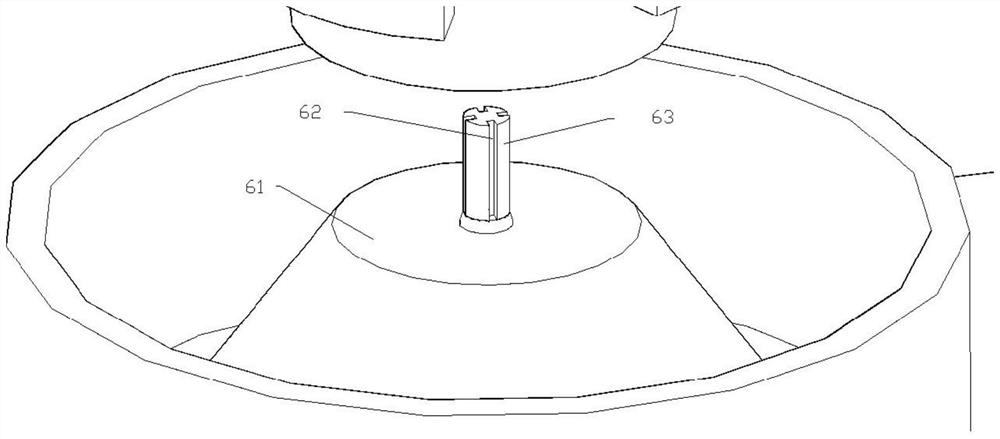

[0019] A one-time forming process for milling grooves of a file grinding machine rotor, including: step 1, respectively fixing an upper mold 5 and a lower mold 6 on a base, the upper mold 5 is fixed by a three-item clamping plate 8, and the lower mold 6 is rotated by a threaded cylinder and fixed inside the base; Step 2, set the rotor material to be processed on the lower mold 6; Step 3, start the stamping motor 3, and press the upper mold 5 to the bottom with P (P pressure value is determined according to the actual processing situation) pressure Above the mold 6, when there is a depression around the upper edge of the rotor material to be processed, apply 2P pressure and continue to press down on the upper mold 5. When unloading two-thirds of the upper edge of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com