Mold for vehicle skylight assembly and manufacturing process of mold

A technology for automotive sunroofs and molds, applied in vehicle parts, forming tools, manufacturing tools, etc., can solve problems such as affecting processing efficiency, positioning affecting processing accuracy, and increasing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

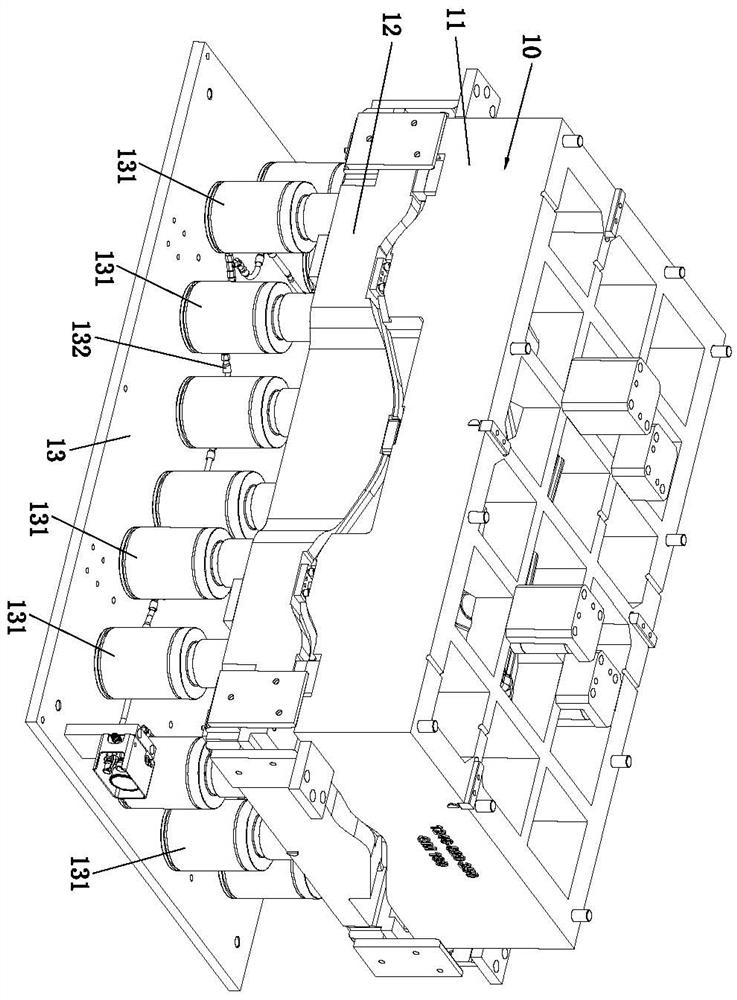

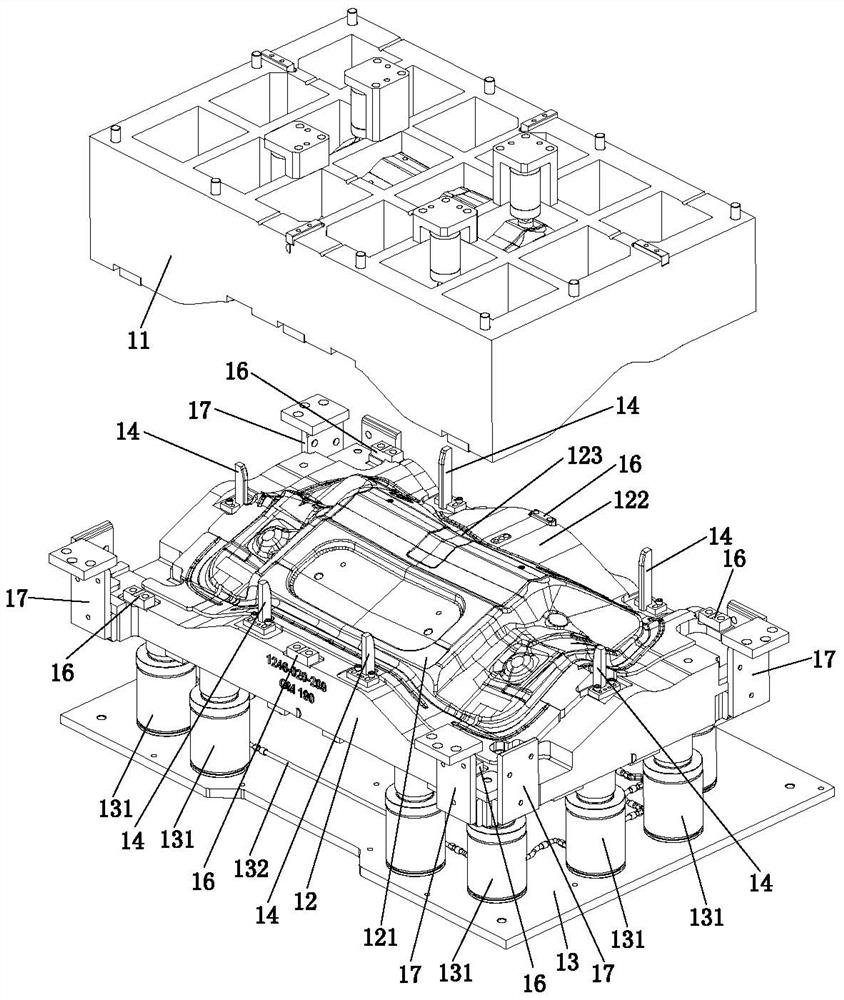

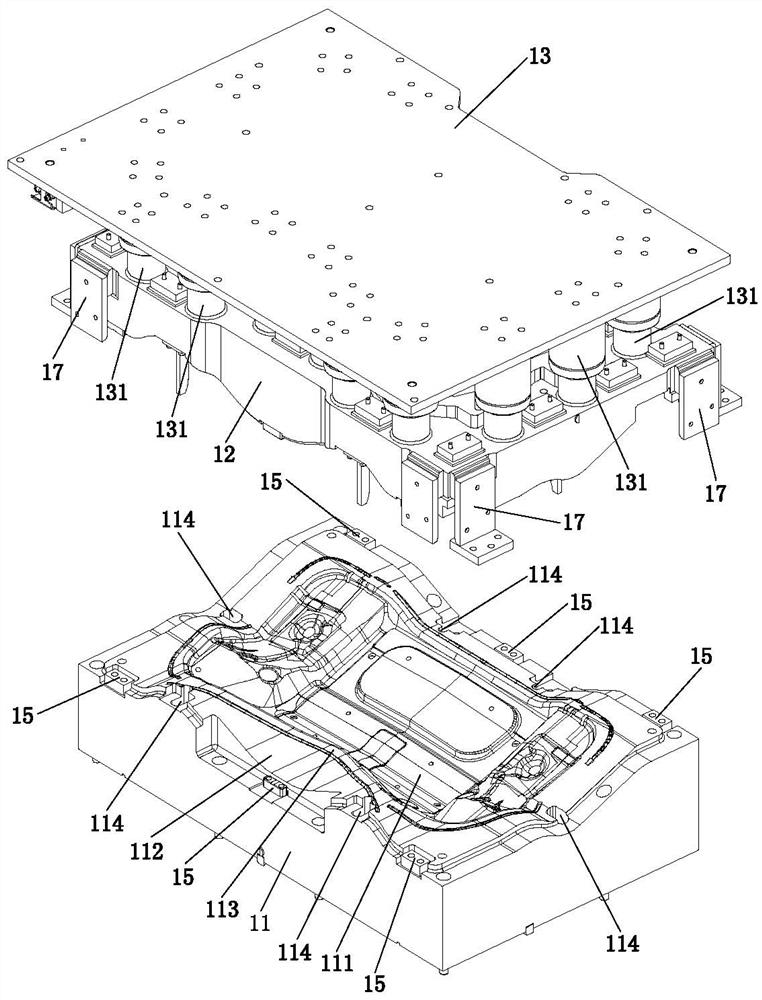

[0045] Please refer to Figure 1 to Figure 21 As shown, it shows the specific structure of the embodiment of the present invention.

[0046] A mold for an automobile sunroof assembly, which sequentially includes a drawing die 10, a first shearing die 20, a second shearing die 30, a shaping die 40, a third shearing die 50, and a first shearing and punching die 60 . The second shearing and punching die 70 .

[0047]Specifically, the drawing die 10 includes a first upper die 11 and a first lower die 12, the lower surface of the first upper die 11 is provided with a die 111, and one side of the die 111 is provided with a pressure variable cavity 112 , the upper surface of the first lower die 12 is provided with a punch 121, one side of the punch 121 is provided with a pressure change ring 122, the die 111 is set corresponding to the punch 121, and the pressure change chamber 112 is connected to the pressure change ring 122 is set correspondingly; the connection between the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com