A waste treatment process for magnet processing

A technology for waste treatment and magnets, which is applied in the direction of magnetic objects, grain treatment, magnetic materials, etc., can solve the problems of low efficiency of magnet waste treatment, performance degradation of NdFeB magnets, and low recovery rate of magnet waste, so as to improve the utilization of waste resources rate, reduce contact opportunities, and reduce the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A waste treatment process for magnet processing, specifically comprising the following steps:

[0041] Step S1, waste pretreatment: take the magnet waste, put it into the ultrasonic cleaning tank, add detergent aqueous solution to the ultrasonic cleaning tank, the volume ratio of the magnet waste to the detergent aqueous solution is 1:2, and then perform ultrasonic cleaning for 15 minutes; Rinse the cleaned magnet waste with clean water for 3 minutes, then put the magnet waste into the oven, set the oven at 100°C, and bake for 30 minutes;

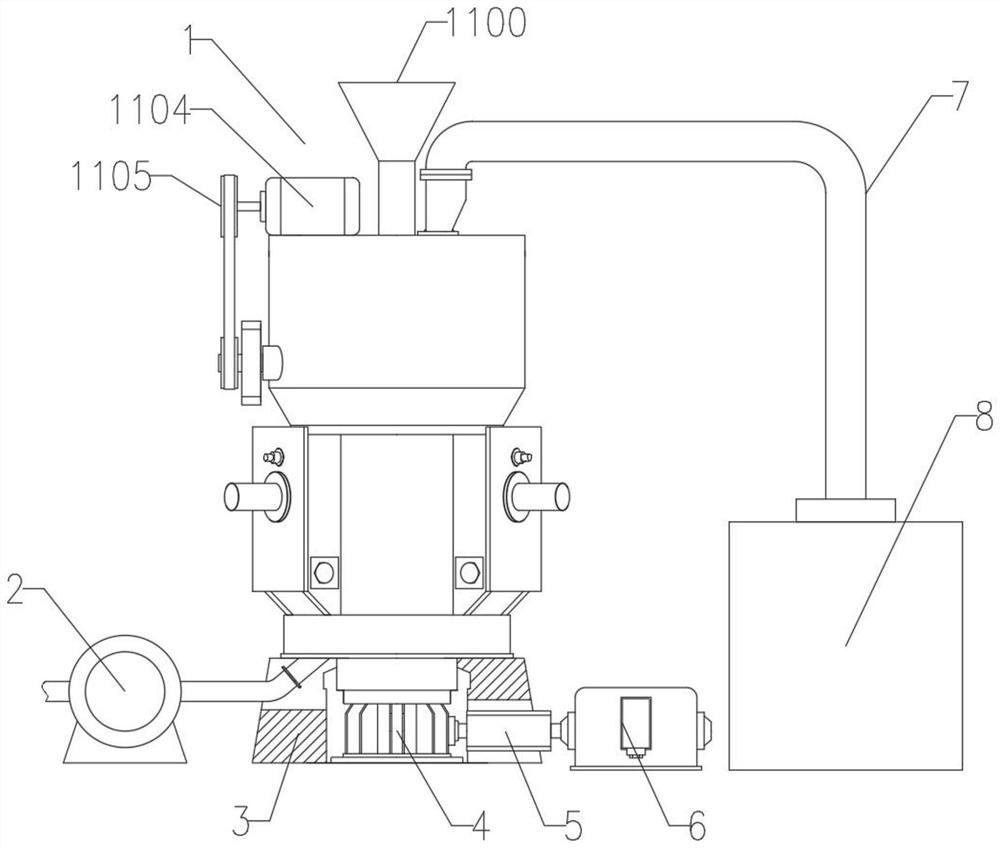

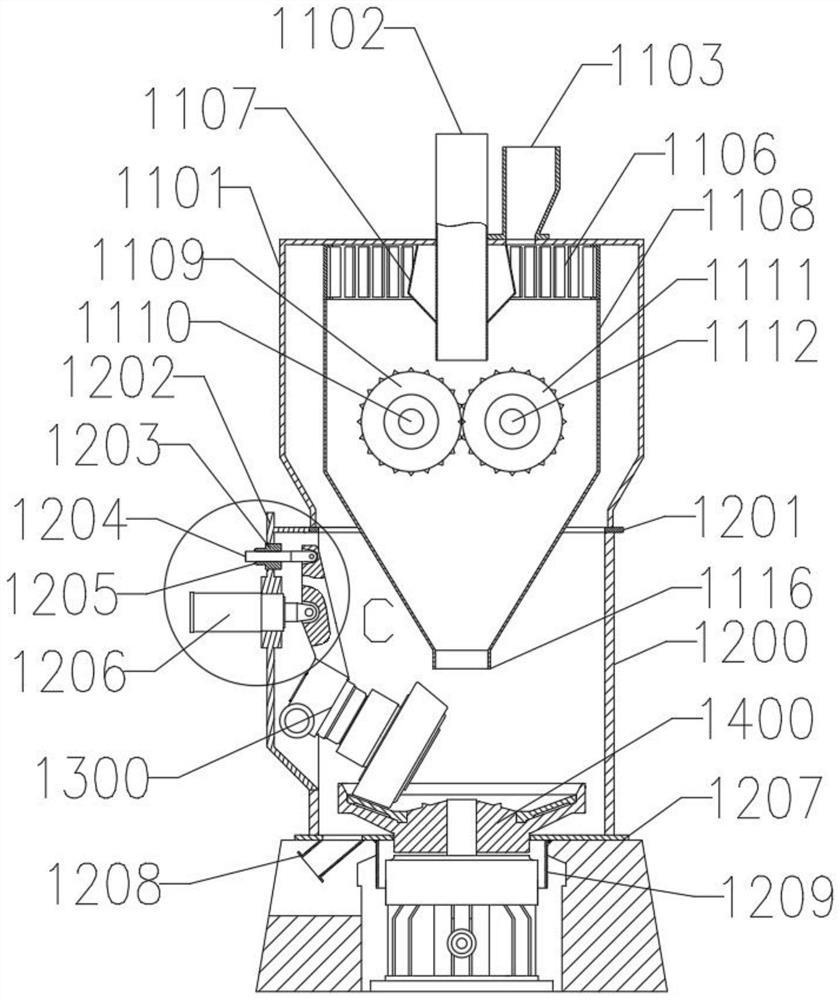

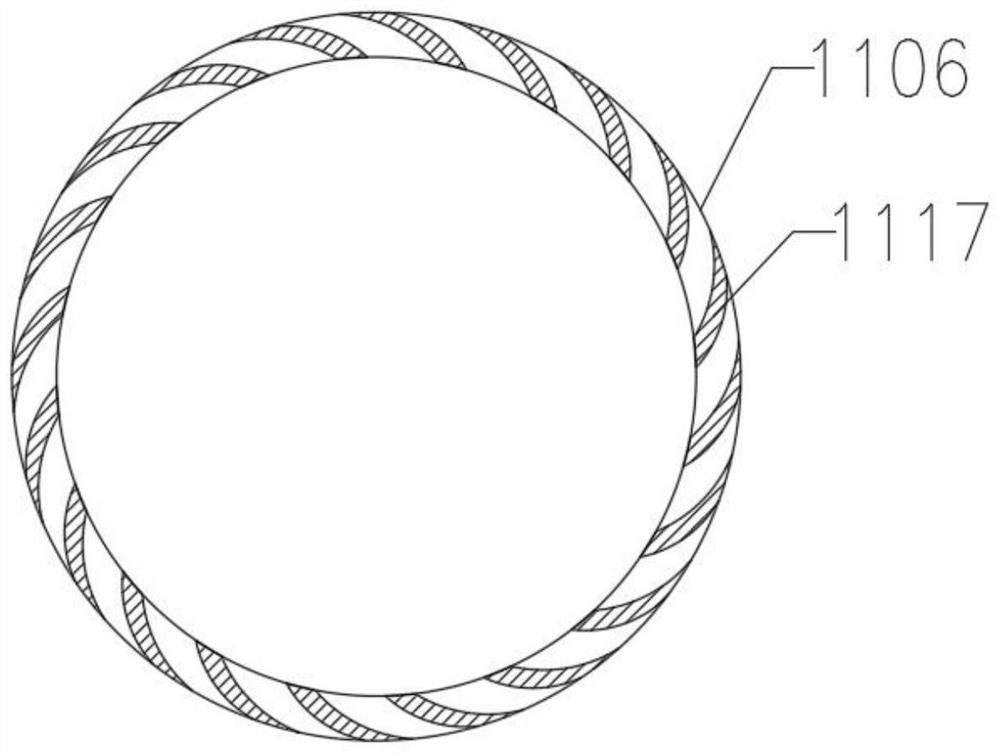

[0042] Step S2, grinding and making powder: take the magnet waste processed in step S1, add it to the magnet crushing and grinding equipment, and grind it into a 3.5 μm magnet powder under the protection of an inert gas, add a lubricant to the magnet powder and mix, the lubricant The amount added is 0.02% of the mass of the magnet powder;

[0043] Step S3, magnetic field molding: Add the crushed and mixed magnet powder in step S2 to...

Embodiment 2

[0049] A waste treatment process for magnet processing, specifically comprising the following steps:

[0050] Step S1, waste pretreatment: take the magnet waste, put it into the ultrasonic cleaning tank, add detergent aqueous solution to the ultrasonic cleaning tank, the volume ratio of the magnet waste to the detergent aqueous solution is 1:2, and then perform ultrasonic cleaning for 18 minutes; Rinse the cleaned magnet waste with clean water for 4 minutes, then put the magnet waste into the oven, set the oven at 150°C, and bake for 35 minutes;

[0051] Step S2, grinding and making powder: Take the magnet waste processed in step S1, add it to the magnet crushing and grinding equipment, and grind it into a 4 μm magnet powder under the protection of an inert gas, add a lubricant to the magnet powder and mix it, add the lubricant The amount is 0.02% of the mass of the magnet powder;

[0052] Step S3, magnetic field molding: Add the crushed and mixed magnet powder in step S2 to ...

Embodiment 3

[0058] A waste treatment process for magnet processing, specifically comprising the following steps:

[0059] Step S1, waste pretreatment: take the magnet waste, put it into the ultrasonic cleaning tank, add detergent aqueous solution to the ultrasonic cleaning tank, the volume ratio of the magnet waste to the detergent aqueous solution is 1:2, and then perform ultrasonic cleaning for 20 minutes; Rinse the cleaned magnet waste with clean water for 5 minutes, then put the magnet waste into the oven, set the oven at 200°C, and bake for 40 minutes;

[0060] Step S2, grinding and making powder: Take the magnet waste processed in step S1, add it to the magnet crushing and grinding equipment, and grind it into a 5 μm magnet powder under the protection of an inert gas, add a lubricant to the magnet powder and mix it, add the lubricant The amount is 0.02% of the mass of the magnet powder;

[0061] Step S3, magnetic field molding: put the crushed and mixed magnet powder in step S2 int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com