WS2/CNTs modified diaphragm of lithium-sulfur battery and preparation method of WS2/CNTs modified diaphragm

A lithium-sulfur battery and battery separator technology, which is applied in the field of new energy materials and devices, can solve the problems of incomplete material functions and limited improvement in battery performance, and achieves reduction of electrochemical polarization, good electronic pathways, and accelerated Effects of Electron and Ion Transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

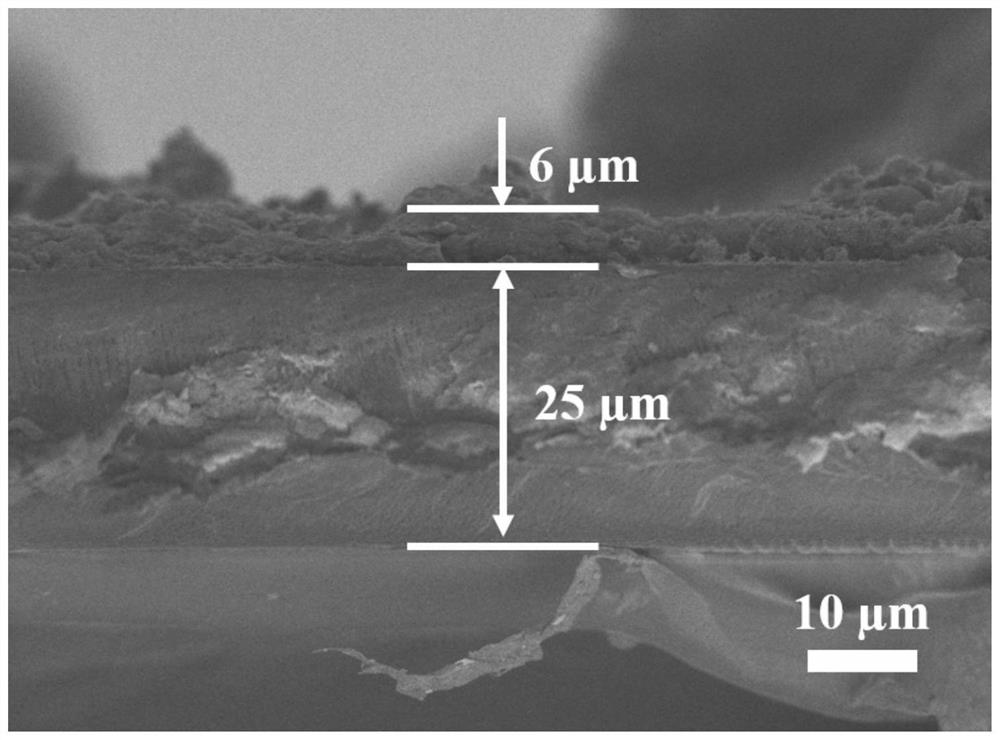

[0040] This embodiment provides a lithium-sulfur battery WS 2 / CNTs modified diaphragm, which consists of two parts: a diaphragm substrate and a modified layer laid on one side of the diaphragm substrate. The separator substrate is a common commercial battery separator substrate, and the modified layer is laid on one side of the separator substrate by WS 2 / CNTs composite material.

[0041] The diaphragm substrate has a planar structure and a large number of through holes, which can be polypropylene (PP) porous membrane, polyethylene (PE) porous membrane, polyethylene / polypropylene composite porous membrane, polyimide diaphragm, polyethylene terephthalate One of the diester-based non-woven separators. In this example, the separator substrate was a commercially available porous polypropylene (PP) membrane (Celgard 2500).

[0042] This embodiment provides a lithium-sulfur battery WS 2 The preparation method of / CNTs modified separator comprises the following steps:

[0043] ...

Embodiment 2

[0068] The preparation method of this embodiment is the same as that of Example 1, except that the WS on the surface of the commercial battery PP separator (Celgard 2500) is suction-filtered in step (6). 2 The loading capacity per unit area of CNTs is 0.48mg / cm 2 , the thickness of the modified layer is 12 μm, and other implementation conditions remain unchanged.

[0069] Compared with Example 1, the WS prepared in this example 2 The lithium-sulfur battery capacity, rate and cycle stability of the lithium-sulfur battery assembled with / CNTs modified separator are roughly the same as in Example 1: the initial discharge capacity at 0.5C is 1052mAh / g, and the specific capacity drops to 803.2mAh / g, the capacity retention rate is 76.3%; the discharge capacity of the first cycle of 1C cycle charge and discharge is 1023mAh / g, and the discharge capacity of the battery after 500 cycles of long cycle can still reach 665.4mAh / g, and the capacity retention rate is 65.0%. In addition, ...

Embodiment 3

[0071] The preparation method of this embodiment is the same as that of Example 1, except that the WS on the surface of the commercial battery PP separator (Celgard2500) is suction-filtered in step (6). 2 The loading capacity per unit area of CNTs is 0.15mg / cm 2 , the thickness of the modified layer is 4 μm, and other implementation conditions remain unchanged.

[0072] Compared with Example 1, the WS prepared in this example 2The electrochemical performance of the lithium-sulfur battery assembled with / CNTs modified separator, such as capacity, rate and cycle stability, is significantly lower than that of Example 1: the initial discharge capacity at 0.5C is 1123mAh / g, and the specific capacity after 200 cycles of charge and discharge Dropped to 678.1mAh / g, the capacity retention rate is 60.4%; the discharge capacity of the first cycle of 1C cycle charge and discharge is 1083mAh / g, and the discharge capacity of the battery after 500 cycles of long cycle can still reach 617....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com