Nanotube NiCo2S4@titanium carbide composite material and preparation method and application thereof

A composite material, titanium carbide technology, applied in titanium carbide, chemical instruments and methods, carbides, etc., can solve problems such as poor specific capacitance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

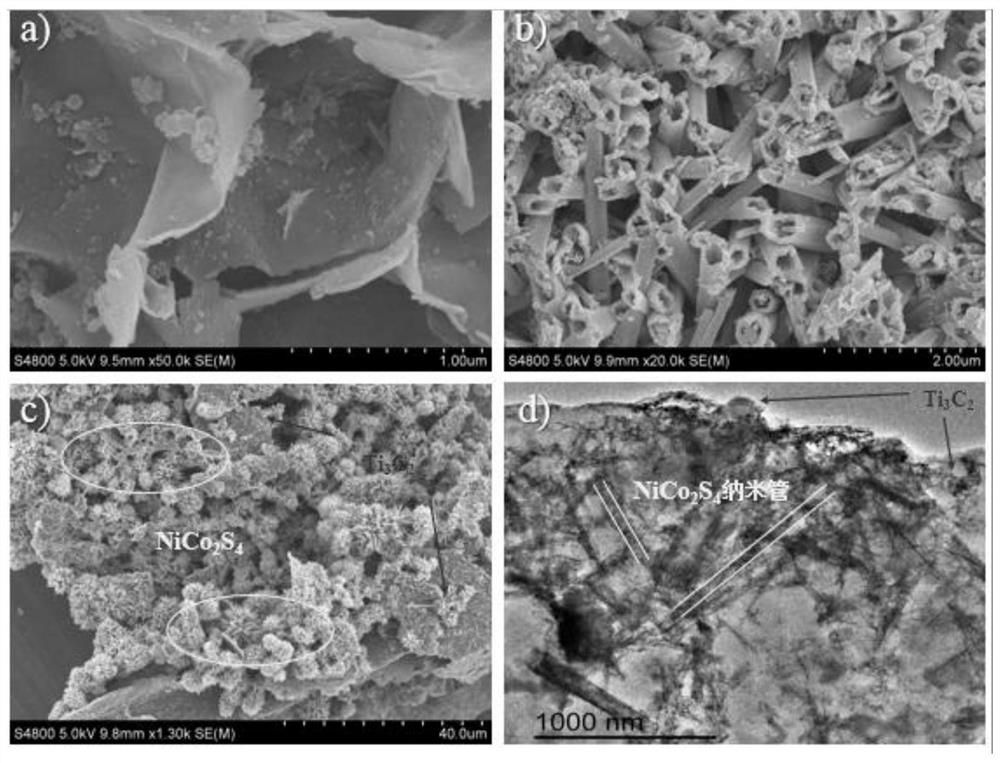

[0034] The invention discloses a nanotubular NiCo 2 S 4 @Titanium carbide composite material and its preparation method and application, the method specifically includes the following steps:

[0035] Step 1, prepare Ti 3 AlC 2 Ceramic powder

[0036] (1) Take TiC powder, Ti powder and Al powder with a total amount of 100g, wherein the molar ratio of the three is TiC:Ti:Al=2:1:1.2, to obtain the mixture A;

[0037] (2) According to the mass ratio of 1:3:1, weigh the mixture A, grinding medium (zirconia ball stone) and ball milling aid (absolute ethanol) in a polytetrafluoroethylene ball mill tank, and perform ball milling at a speed of 350r / min, the ball milling time is 4h, and the powder is obtained after ball milling;

[0038] (3) The obtained powder with uniform particle size is dried at a drying temperature of 40° C. for 24 hours. After drying, the vacuum pressureless sintering process is used for sintering, and the heating system is proposed: the heating rate is 8°C...

Embodiment 1

[0050] Step 1, Ti 3 AlC 2 Preparation of ceramic powder

[0051] (1) Take TiC powder, Ti powder and Al powder that total amount is 100g, wherein the molar ratio of the three is TiC:Ti:Al=2:1:1.2;

[0052] (2) Then weigh the mixed material, grinding medium (zirconia ball stone) and ball milling aid (absolute ethanol) according to the mass ratio of 1:3:1 in a polytetrafluoroethylene ball mill tank, and perform ball milling at a speed of 350r / min, ball milling time is 4h;

[0053] (3) Finally, the obtained uniform powder is dried at a drying temperature of 40° C. for 24 hours. After drying, the vacuum pressureless sintering process is used for sintering, and the heating system is proposed: the heating rate is 8°C / min before 900°C, and the temperature is raised at 6°C / min after 900°C. The highest sintering temperature is 1350°C, and at the highest temperature Keep warm for 100min. Cool in the furnace, high-energy ball mill the product for 2 hours, pass through a 200-mesh sie...

Embodiment 2

[0066] Step 1, Ti 3 AlC 2 Preparation of ceramic powder

[0067] (1) Take TiC powder, Ti powder and Al powder that total amount is 100g, wherein the molar ratio of the three is TiC:Ti:Al=2:1:1.2;

[0068] (2) Then weigh the mixed material, grinding medium (zirconia ball stone) and ball milling aid (absolute ethanol) according to the mass ratio of 1:3:1 in a polytetrafluoroethylene ball mill tank, and perform ball milling at a speed of 350r / min, ball milling time is 4h;

[0069] (3) Finally, the obtained uniform powder is dried at a drying temperature of 40° C. for 24 hours. After drying, the vacuum pressureless sintering process is used for sintering, and the heating system is proposed: the heating rate is 8°C / min before 900°C, and the temperature is raised at 6°C / min after 900°C. The highest sintering temperature is 1350°C, and at the highest temperature Keep warm for 100min. Cool in the furnace, high-energy ball mill the product for 2 hours, pass through a 200-mesh sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com