Construction process for combining anti-buckling quick frame with modified ABS plastic formwork

A technology of ABS plastic and construction technology, which is applied in the field preparation and construction of formwork/formwork components and building components. It can solve the problem of long time for frame erection, low turnover of plywood, and it is difficult to meet the requirements of rapid construction and rapid delivery. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

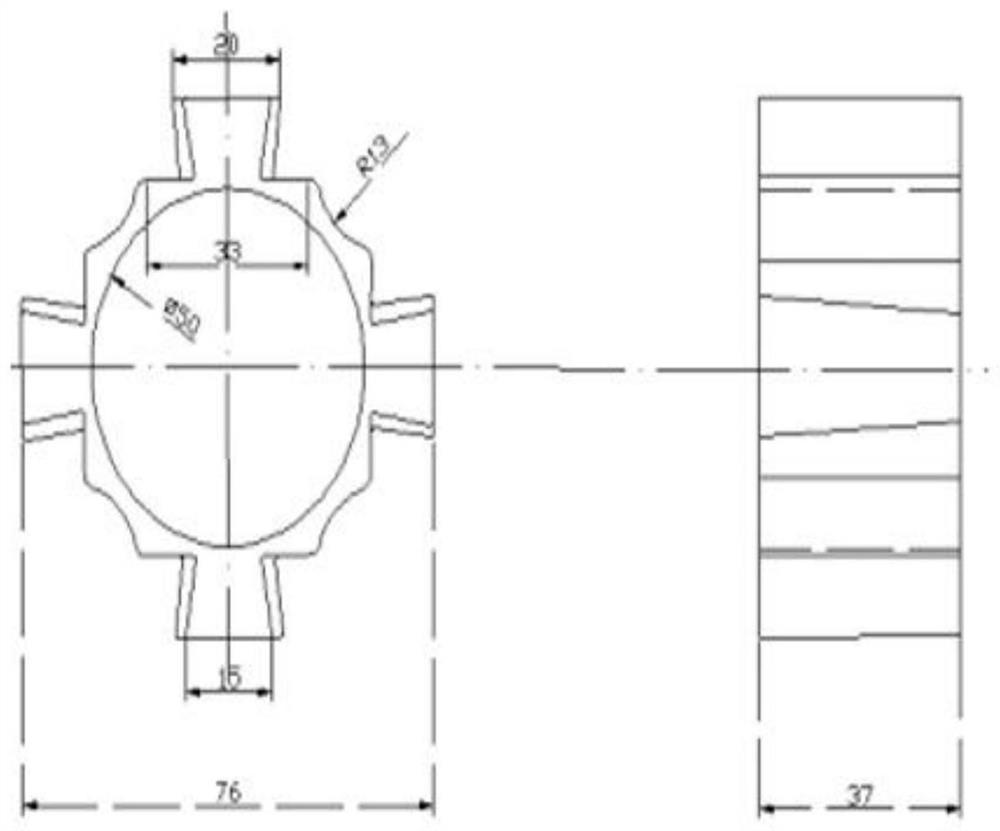

Image

Examples

Embodiment Construction

[0010] The present invention is further described below, but protection scope of the present invention is not limited thereto:

[0011] A kind of anti-buckling fast frame of the present invention combines the construction technique of modified ABS plastic formwork, comprises the following steps:

[0012] 1) Preparation before construction: prepare the materials and utensils used, and reserve them;

[0013] 2) The support system of plastic formwork + fast assembly and disassembly load-bearing frame is mainly composed of a new type of plastic plate as a template, a new type of quick assembly and disassembly load-bearing frame support system as a formwork frame, plus adjustable support, double steel pipe main keel 50mm *100mm wooden square keel is a new type of formwork combination used to support the cast-in-place concrete roof.

[0014] 3) The supporting vertical pipe and cross bar of the fast assembly and disassembly load-bearing frame support system are all made of φ48×3.0 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com