High-adhesion water-based paint suitable for various substrates and preparation method thereof

A high-adhesion, water-based coating technology, applied in the direction of coating, etc., can solve the problem that the delamination of the oil bottom and water surface cannot be effectively solved, there are potential safety hazards, and harmful substances are volatile, and achieve excellent substrate wettability and high storage capacity. The effect of stability and excellent film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

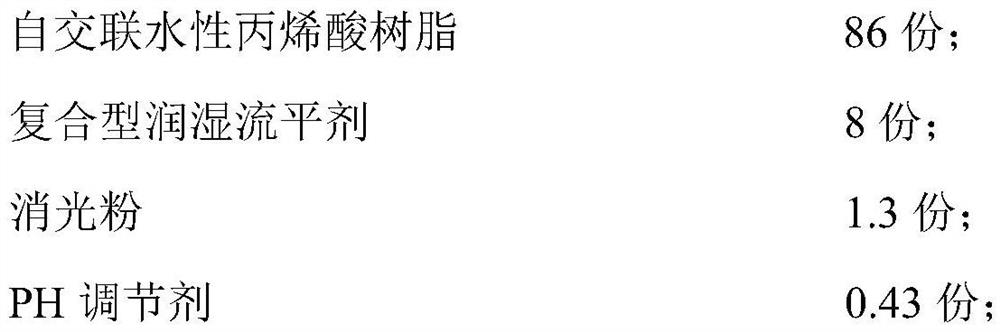

[0041] A kind of high-adhesion water-based coating that is applicable to various substrates of the present embodiment is made up of the raw material of following parts by weight:

[0042]

[0043]

[0044] Among them, the self-crosslinking water-based acrylic resin is composed of DSM NeoCryl XK-14, Opeldi AC3630 and DSM NeoCryl XK-919 in a mass ratio of 1:0.5:0.2.

[0045] Among them, the composite wetting and leveling agent is composed of air chemical Surfynol 104E, BYK BYK-3455 and TgeoWET 270 in a mass ratio of 1:1:0.6.

[0046] The preparation method of the high-adhesion water-based paint applicable to various substrates comprises the steps:

[0047] Step 1: Add self-crosslinking water-based acrylic resin, Dow DPM, Dow DPNB, Dow TPNB, ammonia and diethanolamine into the container, and mix at 600rpm for 16 minutes;

[0048] Step 2: Add Evonik TS-100, Evonik 3400 and BYK-028, and disperse at 1000rpm for 40 minutes;

[0049] Step 3: Add compound wetting and leveling a...

Embodiment 2

[0052] A kind of high-adhesion water-based coating that is applicable to various substrates of the present embodiment is made up of the raw material of following parts by weight:

[0053]

[0054] Among them, the self-crosslinking water-based acrylic resin is composed of DSM NeoCryl XK-14 and Oubaodi AC2403 in a mass ratio of 1:1.

[0055] Among them, the composite wetting and leveling agent is composed of air chemical Surfynol 104E and BYK-349 in a mass ratio of 1:0.5.

[0056] The preparation method of the high-adhesion water-based paint applicable to various substrates comprises the steps:

[0057] Step 1: Add self-crosslinking water-based acrylic resin, Dow DPM, sodium hydroxide and ammonia water into the container, and mix at 600rpm for 20 minutes;

[0058] Step 2: Add BYK-024 and BYK-028 and disperse at 1000rpm for 30 minutes;

[0059] Step 3: Add compound wetting and leveling agent, mix at 600rpm for 12 minutes;

[0060] Step 4: Add TEGO ViscoPlus 3030 and deioniz...

Embodiment 3

[0062] A kind of high-adhesion water-based coating that is applicable to various substrates of the present embodiment is made up of the raw material of following parts by weight:

[0063]

[0064] Among them, the self-crosslinking water-based acrylic resin is composed of DSM NeoCryl XK-14 and DSM NeoCryl XK-15 in a mass ratio of 1:0.7.

[0065] Among them, the composite wetting and leveling agent is composed of air chemical Surfynol 104E and BYK-3455 in a mass ratio of 1:1.5.

[0066] The preparation method of the high-adhesion water-based paint applicable to various substrates comprises the steps:

[0067] Step 1: Add self-crosslinking water-based acrylic resin, Dow DPM and triethanolamine into the container, and mix at 600rpm for 10 minutes;

[0068] Step 2: Add Evonik 3300, Grace ED-2, BYK-024 and TEGO Airex 902W, and disperse at 1000rpm for 35 minutes;

[0069] Step 3: Add compound wetting and leveling agent, mix at 600rpm for 10 minutes;

[0070] Step 4: Add Deqian ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com