A preparation method of a high-energy explosive filled three-dimensional graphene frame composite structure

A frame structure, high-energy explosive technology, applied in graphene, explosives processing equipment, explosives, etc., can solve the problems of poor safety, less application of high-energy explosives, controlled safety, etc., to improve safety performance, achieve explosive performance, and reduce explosives. Sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Measure 15ml of a graphene oxide aqueous solution with a concentration of 2mg / ml, place it in a stainless steel reaction kettle lined with polytetrafluoroethylene, seal it, and heat it in an oven to 180°C for hydrothermal reaction for 24h. The product was taken out to obtain a graphene gel, which was rinsed several times and freeze-dried to obtain a three-dimensional graphene framework structure.

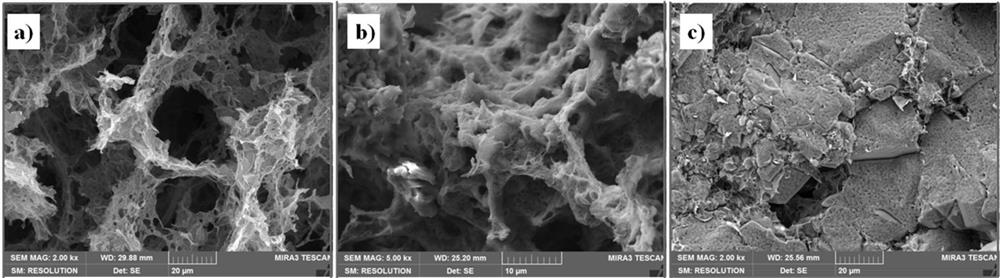

[0030] figure 1 (a) is the SEM morphology of the three-dimensional graphene framework structure, and an obvious network structure can be seen, indicating that the three-dimensional graphene framework structure has been successfully prepared.

[0031] The obtained three-dimensional graphene frame structure is used as a template, and the CL-20 acetone saturated solution is added to the three-dimensional graphene frame structure by using the template adsorption explosive solution import method, and heated at a constant temperature of 60°C in a vacuum drying oven for 20 to 25 min...

Embodiment 2

[0041] Measure 20ml of graphene oxide aqueous solution with a concentration of 1mg / ml, place it in a sample bottle with a sealed cap, and add 0.12g of reducing agent ethylenediamine. Cover with a sealed lid, shake evenly, and place in an oven at 85°C to react for 24 hours. The product was taken out, slowly transferred to deionized water for immersion, and washed several times to remove unreacted reducing agent and impurities, and freeze-dried to obtain a three-dimensional graphene framework structure.

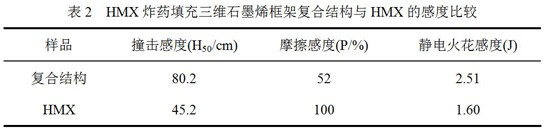

[0042] The obtained three-dimensional graphene framework structure was used as a template, and the HMX acetone saturated solution was added to the three-dimensional graphene framework structure by adopting the import method of template adsorption explosive solution, and evaporated in a vacuum drying oven at a constant temperature of 60°C for 20 minutes, and the solvent acetone was evaporated to obtain HMX explosives filled frame composite structure.

[0043] Using the introduc...

Embodiment 3

[0049] Measure 200ml of graphene oxide aqueous solution with a concentration of 20mg / ml, put it in a 250ml beaker, add 2g of resorcinol, 1g of formaldehyde and 10mg of catalyst sodium carbonate. The mixture was transferred to a glass mold, sealed, and heated in an oven at 80°C for 96h. The graphene gel product was taken out from the mold, soaked and cleaned with acetone, supercritical CO 2 dry wet gel, in N 2 Heating at 1050°C for 3 hours under atmosphere to obtain a three-dimensional graphene framework structure.

[0050] The obtained three-dimensional graphene framework structure was used as a template, and the saturated solution of DAAF acetone was added to the three-dimensional graphene framework structure by adopting the import method of template adsorption explosive solution, and evaporated in a vacuum drying oven at a constant temperature of 60°C for 20 minutes, and the solvent acetone was evaporated to obtain DAAF explosives filled frame composite structure.

[0051...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com