Rapid coloring process of lithium disilicate microcrystalline glass

A technology of lithium disilicate and glass-ceramics, which is applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of affecting the color matching effect and easy wear of the dyed layer, so as to achieve simple process flow, improve translucency and Surface gloss, fast coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: Lithium disilicate glass-ceramic is prepared as follows:

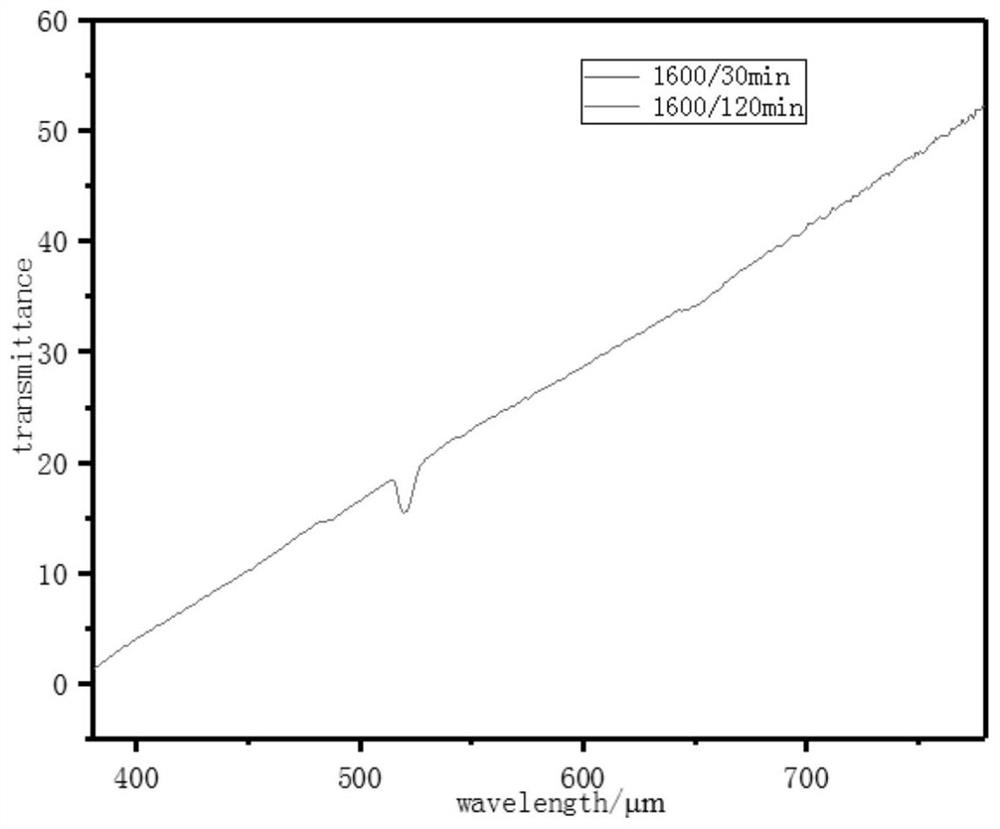

[0034] (1) Weigh the original powder and coloring material respectively according to the proportioning in Table 1, and the coloring material adopted in the present embodiment is CeO 2 , Mix the original powder and color evenly and place them in a muffle furnace to remove carbon and nitrogen respectively, then put them into a high-temperature program-controlled furnace at 1600°C for 30 minutes and 120 minutes of melting, and then pour the melt into a rectangular mold .

[0035] (2) Then put the formed colored glass block into the annealing furnace quickly, heat it at 580° C. for 30 minutes to carry out stress relief annealing, and finally let it cool with the furnace;

[0036] (3) cutting and polishing the colored glass blocks cooled with the furnace, and finally putting them into a program-controlled furnace for nucleation and crystallization treatment, and then obtaining colored lithium disilicat...

Embodiment 2

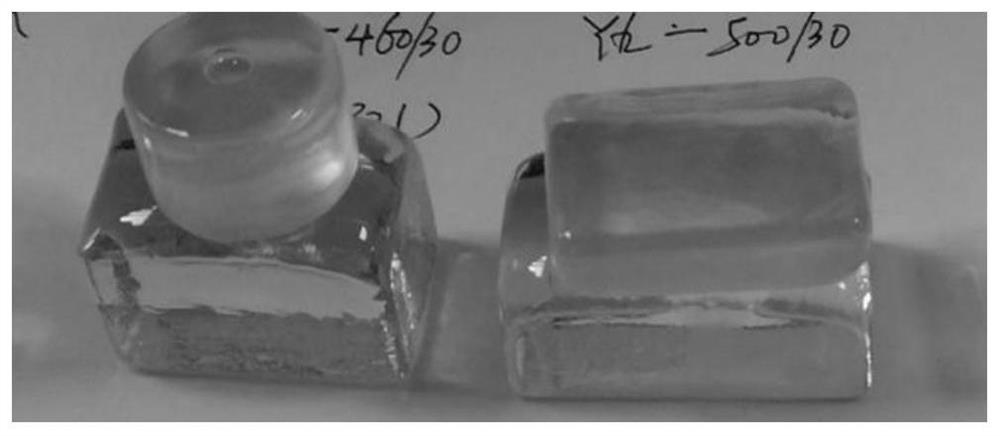

[0043] Weigh a certain amount of glass raw powder according to the ratio in Table 1, without adding coloring material. According to the preparation method described in Example 1, after melting at 1600°C for 30 minutes, pour a part of the melt into a rectangular mold, then quickly put the formed colored glass block into an annealing furnace, and keep warm at 500°C and 460°C for 30 minutes respectively Perform stress relief annealing and finally allow to cool in the furnace. A preliminarily dyed uncrystallized glass block is obtained. figure 2 It is the color morphological diagram of the uncrystallized glass block. Under the same annealing time of 30 minutes, the annealed glasses at 460°C and 500°C are amber yellow, and the glass is very homogeneous and transparent without obvious defects or bubbles. It shows that this annealing temperature can obtain glass crystals with better uniform color, which meets the requirements of bioaesthetics and the production standards of dental ...

Embodiment 3

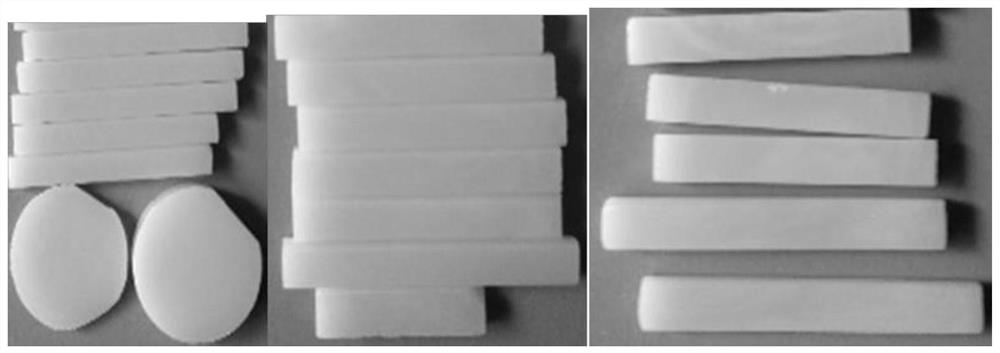

[0045] According to the ratio in Table 1, the original powder and the colorant were weighed respectively, and the colorant in this embodiment was Er2 o 3 . According to the preparation method described in Example 1, after melting at 1600°C for 120 minutes, pour a part of the melt into a rectangular mold, then quickly put the formed colored glass block into an annealing furnace, and keep it at 460°C and 540°C for 30 minutes, Heat at 560°C for 30min, 90min and 150min for stress relief annealing, and finally let it cool with the furnace. A dyed glass matrix is obtained, which is then crystallized. Figure 4 It is the physical picture of the final crystallized glass-ceramics at different annealing temperatures. From 530°C, 540°C, 550°C, 560°C to 580°C, the annealed glass changes from light purple to purple to deep purple, and the glass gradually precipitates Filamentous milky white crystals, the glass becomes heterogeneous and transparent, indicating that this process can be u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com