Tail gas purification device for activated carbon lab-scale activation furnace

A tail gas purification device and activated carbon technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as environmental pollution and physical hazards of testing personnel, and achieve the effect of less environmental pollution and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

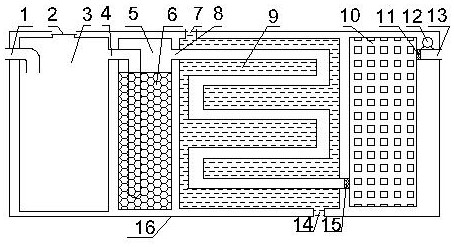

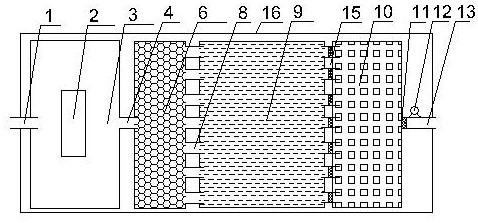

[0013] figure 1 The tail gas purification device of the activated carbon small-scale activation furnace shown is mainly composed of buffer, steam-water separator, condenser and purifier. The tail gas enters the buffer (3) through the intake pipe (1) under the action of the fan. ) to form a stable gas source, the gas enters the steam-water separator through the air pipe (4) to separate gas and liquid, the gas enters the condenser through the condenser inlet pipe (8) to cool down, and the low-temperature gas then passes through the condenser outlet pipe and the purifier screen ( 15) It enters the purifier (10), becomes clean gas after being purified by the purifier, and is discharged into the atmosphere through the separator (11), fan (12) and outlet pipe (13) of the purifier.

[0014] The installation and maintenance methods of this device are:

[0015] 1. The exhaust gas purification device of the activated carbon small-scale activation furnace is installed at the exhaust gas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com