Multi-layer co-extrusion production technology for bidirectional tensile polyethylene antibacterial anti-fogging film

A biaxial stretching and multi-layer co-extrusion technology, which is applied in the direction of flat products, household appliances, and other household appliances, can solve the problems of poor optical and mechanical properties of products, small vertical and horizontal stretch ratios, and low output of extruders. , to achieve the effects of high production efficiency, improved stability and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

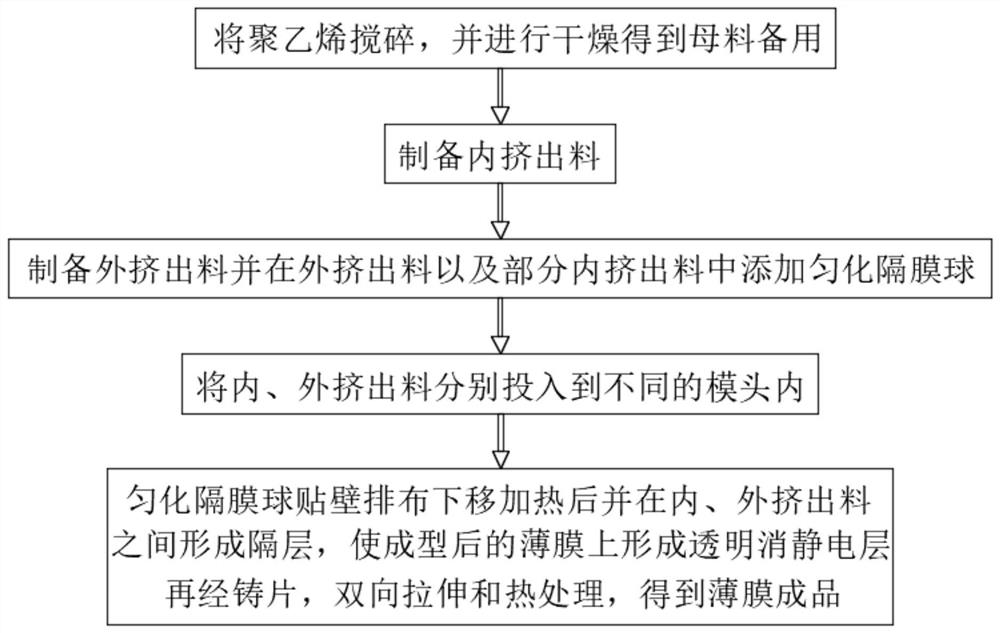

[0047] see figure 1 , a multi-layer co-extrusion production process of biaxially oriented polyethylene antibacterial antifog film, comprising the following steps:

[0048] S1, first crush the polyethylene, and dry to obtain the masterbatch for subsequent use;

[0049] S2. Take part of the polyethylene masterbatch and add antistatic agent and antifogging agent to it to obtain the inner extruded material;

[0050] S3. Take polyethylene heat-sealing material and matting material for mixing, and add anti-fog agent, antibacterial material, anti-sticking agent, and mix evenly to obtain the outer extruded material, and add homogenizer to the outer extruded material and part of the inner extruded material diaphragm ball;

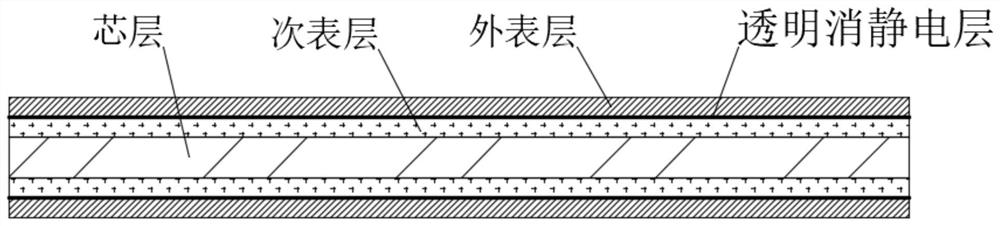

[0051] S4. Please refer to Figure 3-4 In the figure, a represents the inner extrusion material, b represents the outer extrusion material, c represents the interlayer, and d represents the homogenizing distributor, and put different inner extrusion materials and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com