MOFs mixed matrix filtering material for sewage treatment and preparation method thereof

A filter material and mixed matrix technology, applied in water/sludge/sewage treatment, osmosis/dialysis water/sewage treatment, sustainable biological treatment, etc., can solve the problem that the reverse osmosis treatment unit cannot operate normally and the ultrafiltration membrane is easy to foul Blocking, high investment costs and other problems, to achieve the effect of good effluent water quality, strong pollution holding capacity, and high filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add IRMOF series materials, ZIF series materials, and CPL series materials into modifier acid anhydrides. After the ester bonds in the anhydrides are broken, they react with functional groups in MOFs. After surface modification, they are mixed with polysulfone respectively, and then melt-spun to make a 8-55μm fiber filaments. A MOFs mixed matrix filter material with a ratio of polymer to MOFs material of 98.5:1.5, a pore size of 0.2 μm, a porosity of 70%, and a filter layer thickness of 1100 mm was prepared by fiber filament construction, combination and stacking methods. The filter material is fixedly installed in a filter tank with a diameter of 1400mm to build an efficient integrated water purification equipment. The equipment is used for domestic sewage (turbidity: 35.5NTU; suspended solids: 71.3mg / L; COD Cr : 70.4mg / L; BOD 5 : 25.8mg / L; ammonia nitrogen: 17.2mg / L;) treatment, at room temperature and 0.15MPa operating pressure, the filtration speed is 38.5-39.2m / h...

Embodiment 2

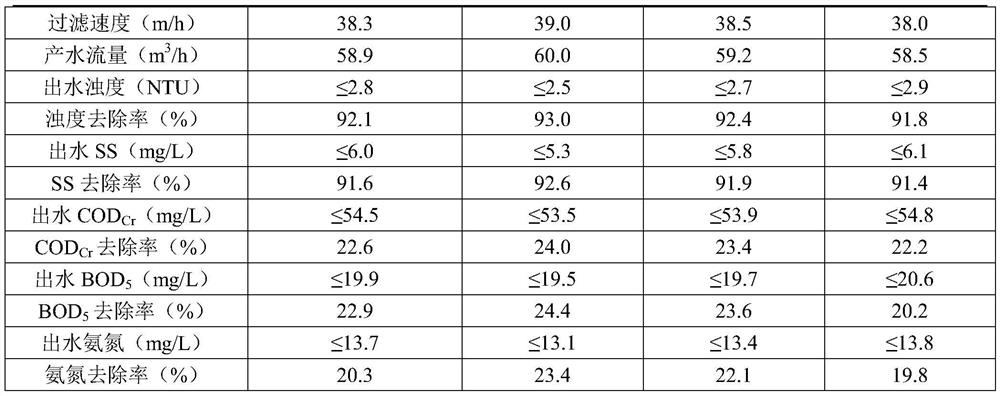

[0032] The IRMOF series materials are added to the modifier acid anhydride. The ester bond in the anhydride is broken and reacts with the functional groups in the MOFs. After surface modification, it is mixed with polysulfone, and then melt-spun to make fibers with a diameter of 8-55 μm. Through the method of fiber filament construction, combination and superposition, the proportions of polymer and MOFs materials are 98:2, 98.5:1.5, 99:1, 99.5:0.5, the pore size is 0.2 μm, and the porosity is 70%. A MOFs mixed matrix filter material with a filter layer thickness of 1100 mm. The filter material is fixedly installed in a filter tank with a diameter of 1400mm to build an efficient integrated water purification equipment. The equipment is used for domestic sewage (turbidity: 35.5NTU; suspended solids: 71.3mg / L; COD Cr : 70.4mg / L; BOD 5 : 25.8mg / L; ammonia nitrogen: 17.2mg / L;) treatment, at room temperature and 0.15MPa operating pressure, the filtration speed is 38.0-39.0m / h, the...

Embodiment 3

[0037] The IRMOF series materials are added to the modifier acid anhydride. The ester bond in the anhydride is broken and reacts with the functional groups in the MOFs. After surface modification, it is mixed with polysulfone, and then melt-spun to make fibers with a diameter of 8-55 μm. Through the fiber filament construction, combination and superposition method, the ratio of polymer to MOFs material is 98.5:1.5, the pore size is 0.1 μm, 0.2 μm, 0.3 μm, the porosity is 70%, and the thickness of the filter layer is 1100mm. MOFs Mixed matrix filter material. The filter material is fixedly installed in a filter tank with a diameter of 1400mm to build an efficient integrated water purification equipment. The equipment is used for coal mine wastewater (turbidity: 61.3NTU; suspended solids: 123.5mg / L; COD Cr : 8.9mg / L; BOD 5 : 4.3mg / L; ammonia nitrogen: 1.7mg / L) treatment, at room temperature and 0.15MPa operating pressure, the filtration speed is 38.2-39.5m / h, the pressure loss...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com