Cinnamon bark extract and preparation method thereof and application of cinnamon bark extract

A technology of cinnamon bark and extract, which is applied in skin care preparations, pharmaceutical formulas, cosmetic preparations, etc. It can solve the problems of unfavorable batch production and complicated preparation process, and achieve the prevention of cell degeneration and aging and high extraction rate , the effect of inhibiting the activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

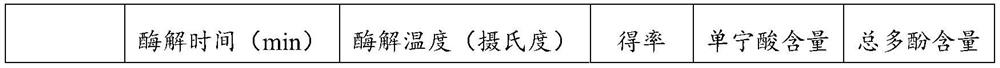

[0047] A preparation method of cinnamon bark extract, is characterized in that, described preparation method comprises the following steps:

[0048] (1) drying and pulverizing the cinnamon bark to obtain coarse powder;

[0049] (2) dissolving the coarse powder in distilled water, adding cellulase for enzymatic hydrolysis, then heating for extraction, and concentrating the extract to obtain an extract;

[0050] The mass fraction of cellulase in distilled water is 0.1%, the solid-liquid ratio of coarse powder and distilled water is 1:10, the enzymolysis time is 30min, the enzymolysis temperature is 40°C, the extraction temperature is 70°C, and the extraction time is 80min;

[0051] (3) Dissolving the extract with 5% acetone aqueous solution, purifying with a macroporous resin gel column, eluting with an eluent, and collecting the eluate;

[0052] The eluent is acetone aqueous solution with a volume fraction of 20%, the volume ratio of the volume of the extract after dissolving ...

Embodiment 2

[0056] A preparation method of cinnamon bark extract, is characterized in that, described preparation method comprises the following steps:

[0057] (1) drying and pulverizing the cinnamon bark to obtain coarse powder;

[0058] (2) dissolving the coarse powder in distilled water, adding cellulase for enzymatic hydrolysis, then heating for extraction, and concentrating the extract to obtain an extract;

[0059] The mass fraction of cellulase in distilled water is 0.5%, the solid-liquid ratio of coarse powder to distilled water is 1:30, the enzymolysis time is 60min, the enzymolysis temperature is 20°C, the extraction temperature is 100°C, and the extraction time is 40min;

[0060] (3) Dissolving the extract with 20% acetone aqueous solution, purifying with a macroporous resin gel column, eluting with an eluent, and collecting the eluate;

[0061] The eluent is an acetone aqueous solution with a volume fraction of 80%, the volume ratio of the volume of the extract after dissolv...

Embodiment 3

[0065] A preparation method of cinnamon bark extract, is characterized in that, described preparation method comprises the following steps:

[0066] (1) drying and pulverizing the cinnamon bark to obtain coarse powder;

[0067] (2) dissolving the coarse powder in distilled water, adding cellulase for enzymatic hydrolysis, then heating for extraction, and concentrating the extract to obtain an extract;

[0068] The mass fraction of cellulase in distilled water is 0.3%, the solid-liquid ratio of coarse powder to distilled water is 1:20, the enzymolysis time is 40min, the enzymolysis temperature is 30°C, the extraction temperature is 90°C, and the extraction time is 60min;

[0069] (3) Dissolving the extract with 15% acetone aqueous solution, purifying with a macroporous resin gel column, eluting with an eluent, and collecting the eluate;

[0070] The eluent is acetone aqueous solution with a volume fraction of 60%. The volume ratio of the volume of the extract after dissolving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com