W-band reconfigurable microstrip filter based on intercalated graphene and manufacturing method thereof

A technology of microstrip filter and intercalated graphite, which is applied in the direction of waveguide devices, electrical components, circuits, etc., can solve the problems of single function and poor flexibility, and achieve the effect of changing single function, improving flexibility and expanding the filtering range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A W-band reconfigurable microstrip filter based on intercalated graphene, including a metal ground plate, a dielectric substrate, a plurality of microstrip patches and a plurality of intercalated graphene structures; wherein a layer is deposited on the bottom surface of the dielectric substrate As for the metal grounding plate, a plurality of patches are arranged in an array on the surface of the dielectric substrate to form a microstrip patch array structure, and a circle of intercalated graphene is arranged around the patch array structure.

[0032] The microstrip patch array structure adopts the design of port diagonalization, forming two coupled microstrip transmission lines of the same length, each of which is formed by coupling three microstrip patches, forming two coupling units in total , the formed band-pass filter is at least two passbands. Since the two paths are completely symmetrical, without considering the adjustment effect of the intercalated graphene str...

Embodiment 2

[0038] A method for making a W-band reconfigurable microstrip filter based on intercalation graphene, comprising the following steps:

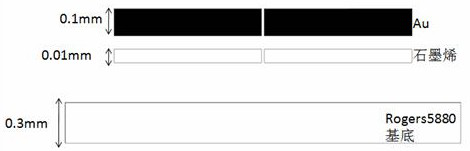

[0039] Step 1. Use Rogers5880 as the dielectric substrate, and grind the Rogers5880 dielectric substrate so that the thickness, surface uniformity and surface finish of the substrate must meet the experimental requirements;

[0040] Step 2. Put the ground dielectric substrate into the vacuum coating machine, and coat a layer of metal Cu on the dielectric substrate as a grounding plate. Since the adhesion of the Rogers5880 dielectric substrate is not strong, it is best to coat a layer of metal Cu before plating Gr;

[0041] Step 3. Deposit a layer of metal Au array microstrip lines on the surface of the dielectric substrate by evaporation and sputtering, that is, the microstrip patch, and evaporate a circle of intercalated graphene structure around the microstrip patch. The graphene Conductivity phase change range ≥ 1000s / m.

Embodiment 3

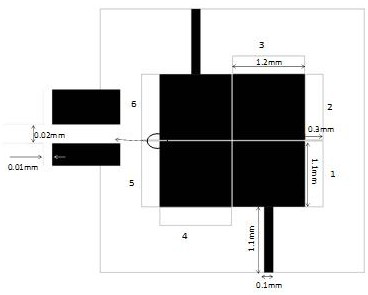

[0043] Refer to attached Figure 1-2 , a multi-passband filter design based on microstrip array patches, where the length of each patch is 1.1mm, the width is 1.2mm, the spacing between patches is 0.02mm, and the width of intercalated graphene is 0.3mm. The distance between the sheet and the intercalated graphene is 0.01mm, the thickness of the patch is 0.1mm, the thickness of the substrate is 0.3mm, the length of the feeder is 1.1mm, the phase change range of the conductivity of the intercalated graphene material is ≥1000s / m, and the phase change switch The design is as follows:

[0044] (1) Phase transition of intercalated graphene at no phase transition;

[0045] (2) figure 1 3 and 4 intercalated graphene phase transitions in ;

[0046] (3) figure 1 Intercalated graphene phase transitions at 1, 2, 5, and 6 in ;

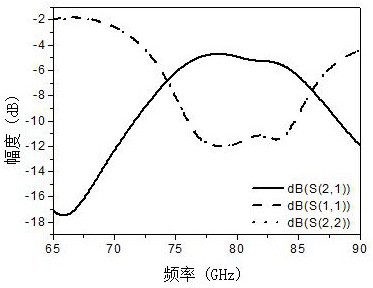

[0047] The phase change return loss and insertion loss are obtained by referring to the attached Figure 3-5 .

[0048] In summary, the present invention is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com