Modeling method of in-situ identification model for hob wear and in-situ identification method for hob wear

A technology of recognition model and modeling method, which is applied in the field of on-site recognition of hob wear and on-site recognition model modeling of hob wear, which can solve the problem of increasing algorithm time complexity, poor recognition effect, and inability to follow the law of data without deviation Estimation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described in detail below in conjunction with the accompanying drawings.

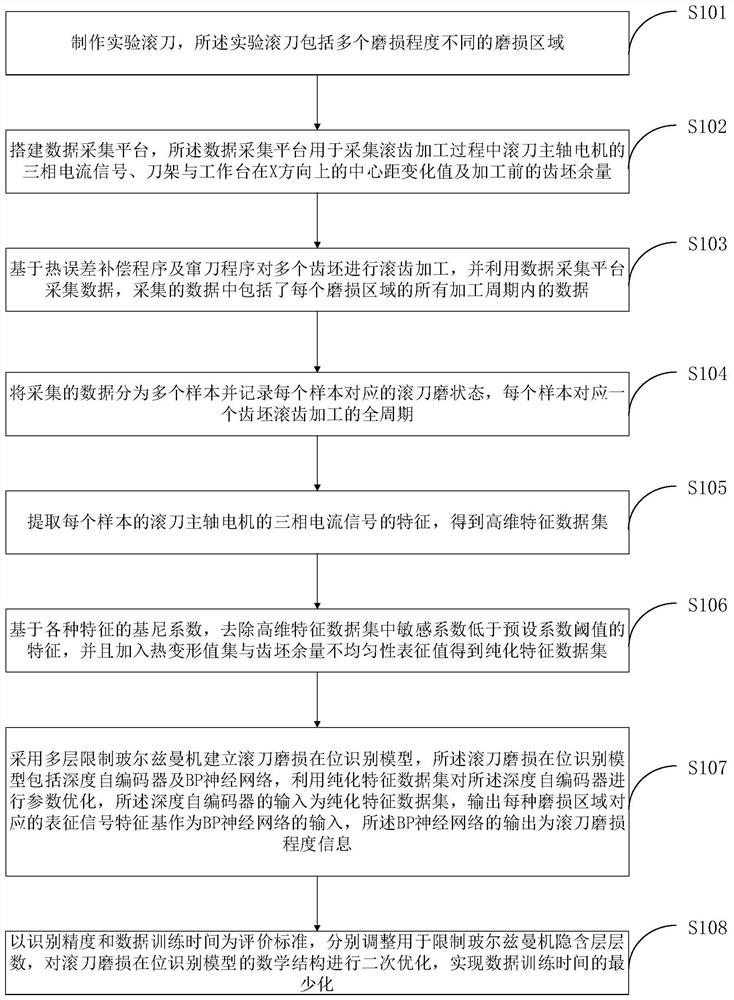

[0043] Such as figure 1 As shown, the present invention discloses a hob wear in-situ recognition model modeling method, including the following steps:

[0044] S101, making an experimental hob, the experimental hob includes a plurality of wear areas with different degrees of wear;

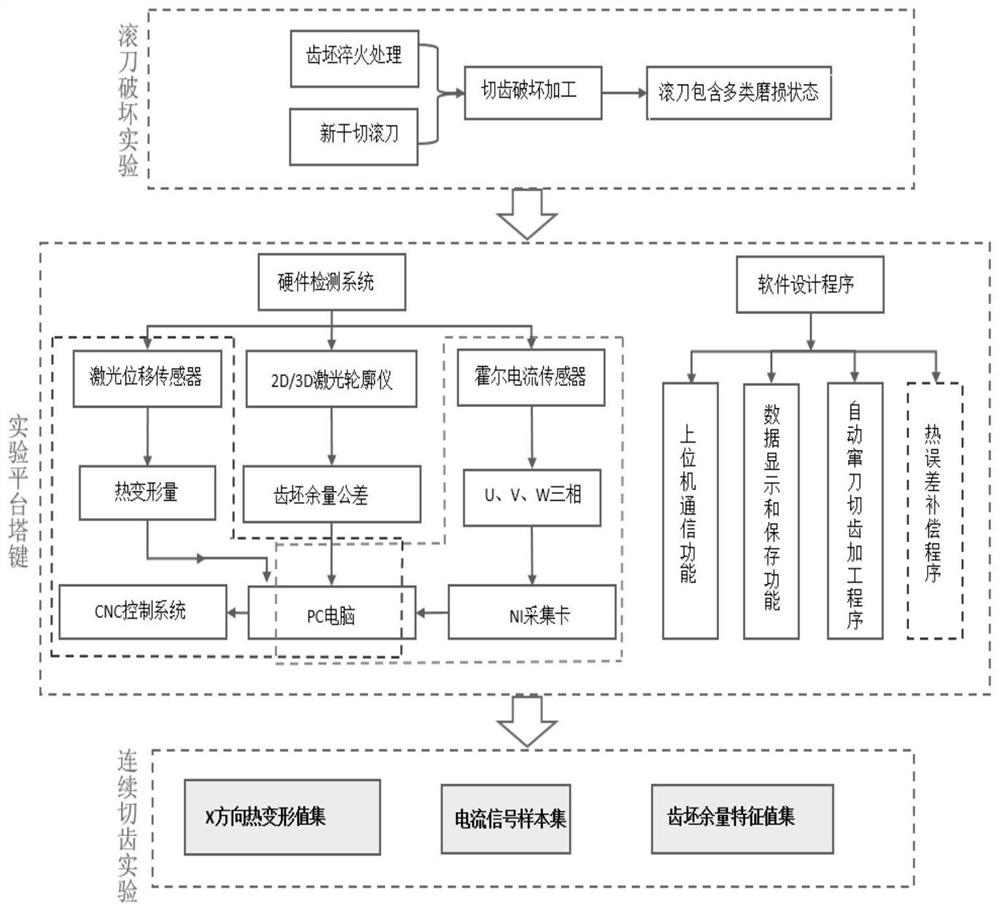

[0045] From step S101 to step S104 of the present invention, taking the YDE3120CNC dry-cut gear hobbing machine tool as an example, a multi-signal monitoring experimental platform for the dry-cut gear making process is built (the Hall sensor collects the motor current signal, and the laser profiler measures the tolerance of the tooth blank margin. , The thermal error real-time detection device independently developed by the project team collects the change of the center distance between the tool holder and the worktable), and carries out controlled gear cutting experiments, so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com