Steam turbine valve steam distribution management function generation method based on CFD method

A function generation, steam turbine technology, applied in geometric CAD, 3D modeling, image data processing, etc., can solve problems such as uneven stress on high-pressure rotors, rising bearing bush temperature, large speed fluctuations, etc., to save labor costs and Time cost, accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described below in conjunction with the accompanying drawings.

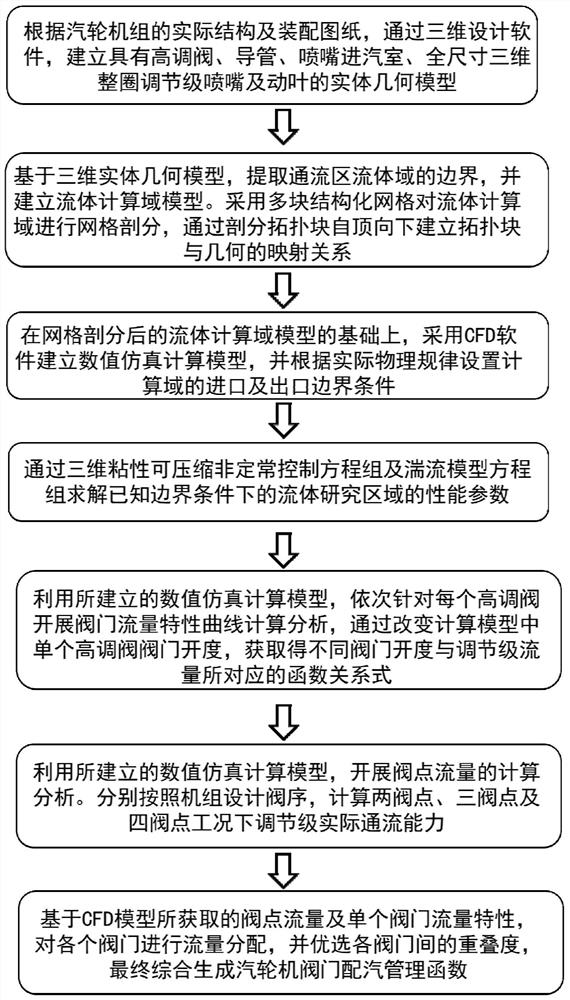

[0068] see figure 1 , the present invention comprises the following steps:

[0069] Step 1. According to the actual structure and assembly drawings of the steam turbine unit, use the 3D design software to establish a solid geometric model with high-speed valves, ducts, nozzle inlet chambers, full-scale 3D full-circle regulating nozzles and moving blades.

[0070] The 3D design software used can be UG, SolidWorks, Pro / E, ANSYS Workbench, etc. Among them, the solid geometric model generation method of high-profile valves, ducts, nozzle inlet chambers, full-scale 3D full-circle regulating nozzles and moving vanes is as follows: The airfoil body is generated by setting out the section curve group, or by using cubic B-spline curves for the section curve.

[0071] The k-degree B-spline curve equation is:

[0072]

[0073] Among them, d i is the control vertex, N i,k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com