Heat treatment process of powder metallurgy aluminum alloy cold-rolled sheet

A technology of powder metallurgy and aluminum alloy, which is applied in the field of aluminum alloy and can solve the problems of unsuitability for industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Prepare a 2A12 aluminum alloy plate with a thickness of 0.5mm;

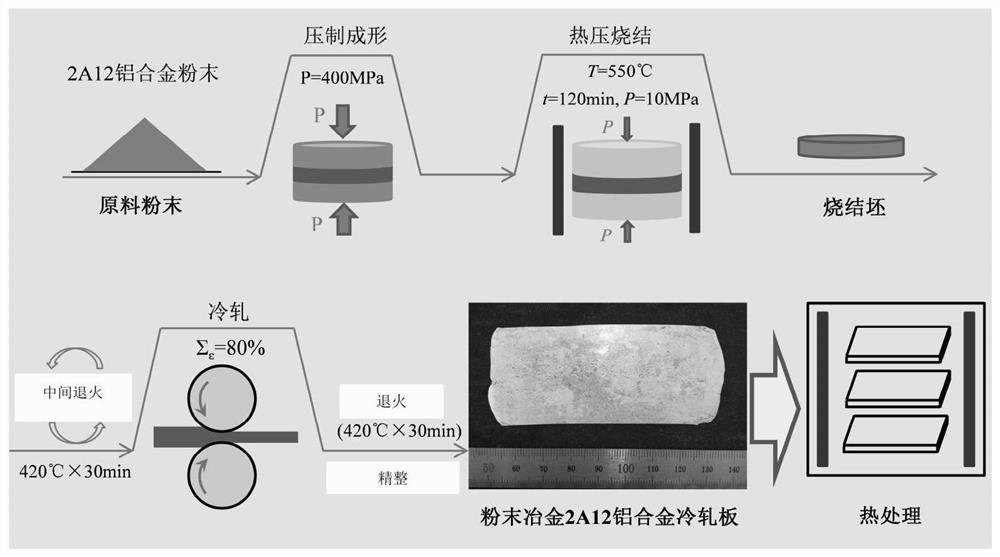

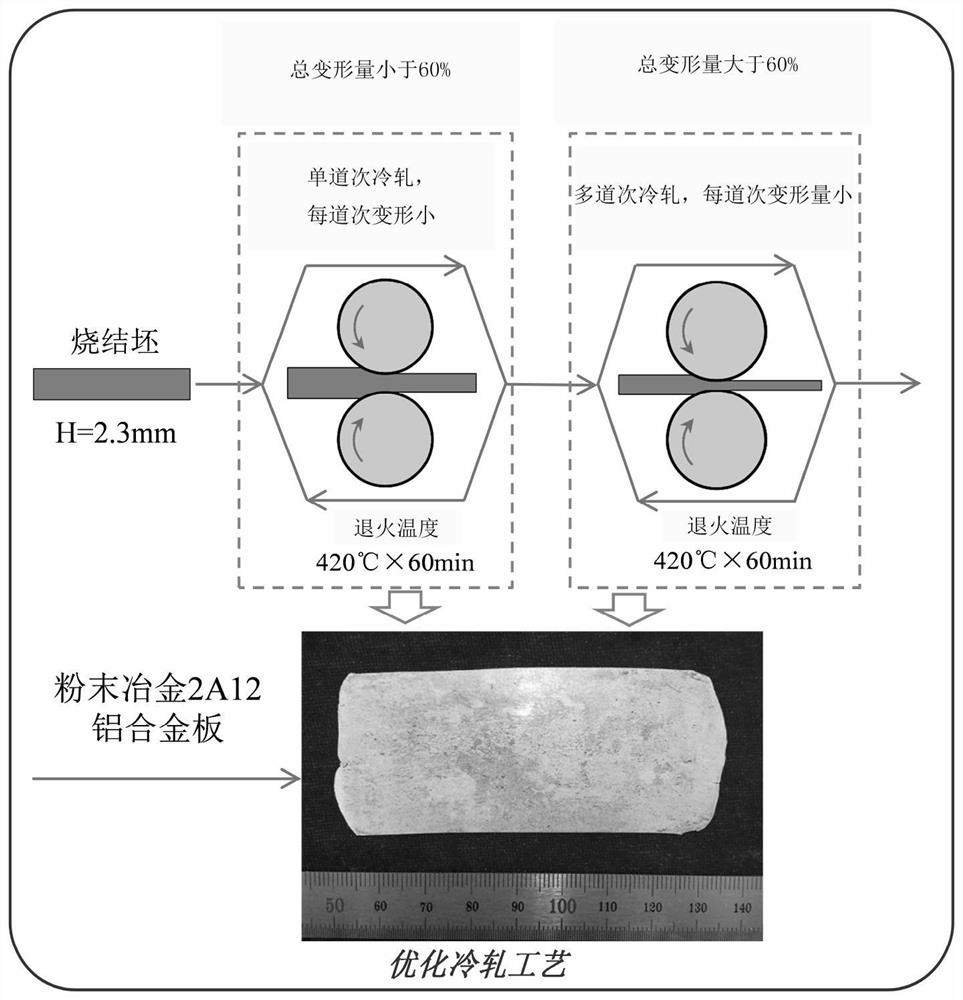

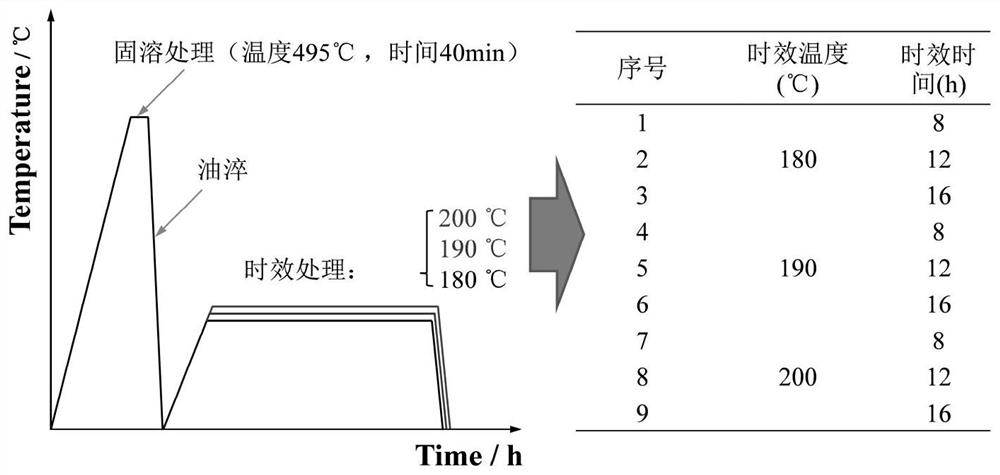

[0056] According to the production method of the present invention, the 250-300 mesh spherical 2A12 aluminum alloy powder (nearly spherical powder prepared by water atomization method) produced by Changsha Tianjiu Metal Material Co., Ltd. is used as raw material powder (its chemical composition meets the requirements of GB / T3190) , the sheet production process is as follows figure 1 As shown, the powder is pressed into a steel mold to prepare a green billet (the thickness of the green billet is 3mm), and the green billet is sintered in a high-vacuum precision vacuum hot-press furnace to prepare a cold-rolled sheet material (sintering temperature 575 ° C, time 120min, The pressure is 10MPa), the sintered billet is annealed, the annealing temperature is 420 °C; the holding time is 60 minutes, after the holding time is completed, it is cooled in the furnace to below 260 °C at a speed of no more than 30 °C / h ...

Embodiment 2

[0064] Prepare a 2A12 aluminum alloy plate with a thickness of 1.0mm;

[0065] Its preparation process is consistent with that of Example 1, see the heat treatment process of Example 1 for details (the total deformation of the plate is 60%). The obtained sheet has a tensile strength of 420MPa, an elongation of 6.28%, and a hardness of 123.06HV.

[0066] The above experiment was repeated 100 times, and the yield was 99%. It can be seen from Examples 1 and 2 that the total deformation of the rolled plate affects its tensile strength.

Embodiment 3

[0068] Prepare a 2A12 aluminum alloy plate with a thickness of 0.5mm;

[0069] According to the production method of the present invention, the 250-300 mesh spherical 2A12 aluminum alloy powder (nearly spherical powder prepared by water atomization method) produced by Changsha Tianjiu Metal Material Co., Ltd. is used as raw material powder (its chemical composition meets the requirements of GB / T3190) , the sheet production process is as follows figure 1 As shown, the powder is pressed into a steel mold to prepare a green billet (the thickness of the green billet is 3mm), and the green billet is sintered in a high-vacuum precision vacuum hot-press furnace to prepare a cold-rolled sheet material (sintering temperature 575 ° C, time 120min, The pressure is 10MPa), the sintered billet is annealed, the annealing temperature is 420 °C; the holding time is 60 minutes, after the holding time is completed, it is cooled in the furnace to below 260 °C at a speed of no more than 30 °C / h ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com