Chromium-vanadium series hot rolled steel wire rod and preparation method thereof, and preparation method of steel wire and hand tool

A technology of steel wire rod and chromium vanadium, which is applied in the field of wire rod steel, can solve the problems that wire rod cannot be processed by cold drawing and the rate of wire breakage is high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] In the second aspect, the embodiment of the present application provides a method for preparing the chrome-vanadium series hot-rolled steel wire rod provided in the embodiment of the first aspect, which includes: rolling the slab with the segregation index standard at the center of the alloy, and spinning Handling and Cooling.

[0053] About the preparation of billet:

[0054] In some possible embodiments, the slab preparation operations include converter smelting treatment, LF refining treatment, RH furnace vacuum treatment, billet protection continuous casting treatment and slab heating treatment.

[0055] In the converter smelting process, for example, the high-drawing carbon tapping operation is adopted, and the content of C element at the end point is required to be 0.10-0.35wt%, and the content of further C element is ≥0.12wt%, which can reduce the number of blowing and ensure The oxygen content in the molten steel is low when the converter is tapped, which reduc...

Embodiment 1

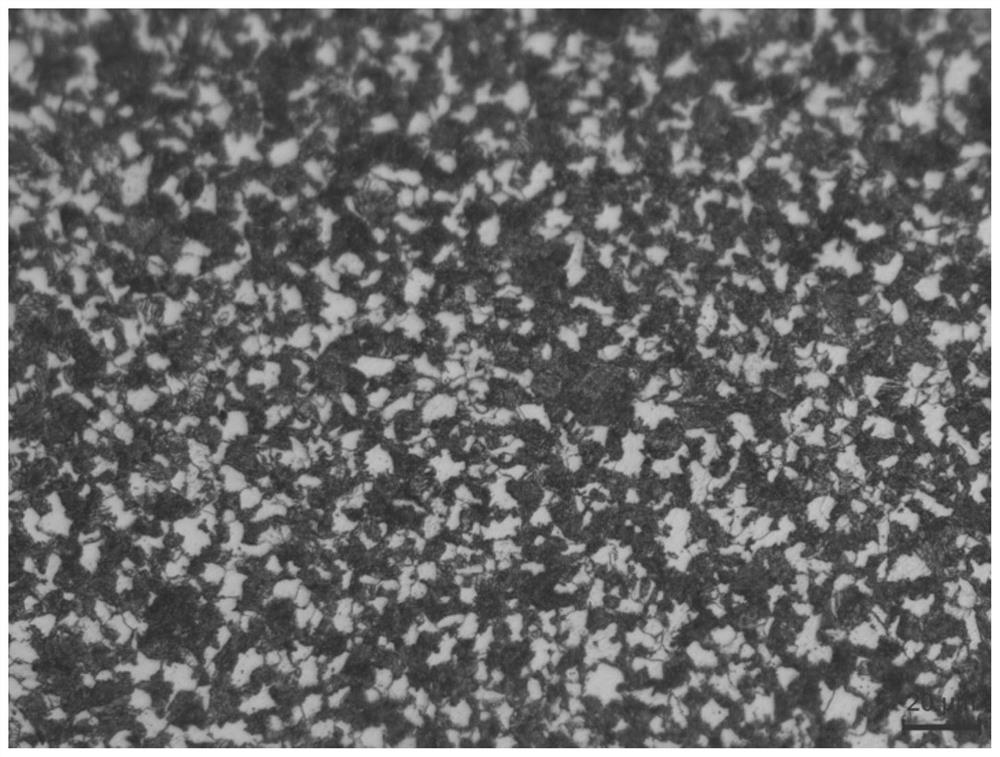

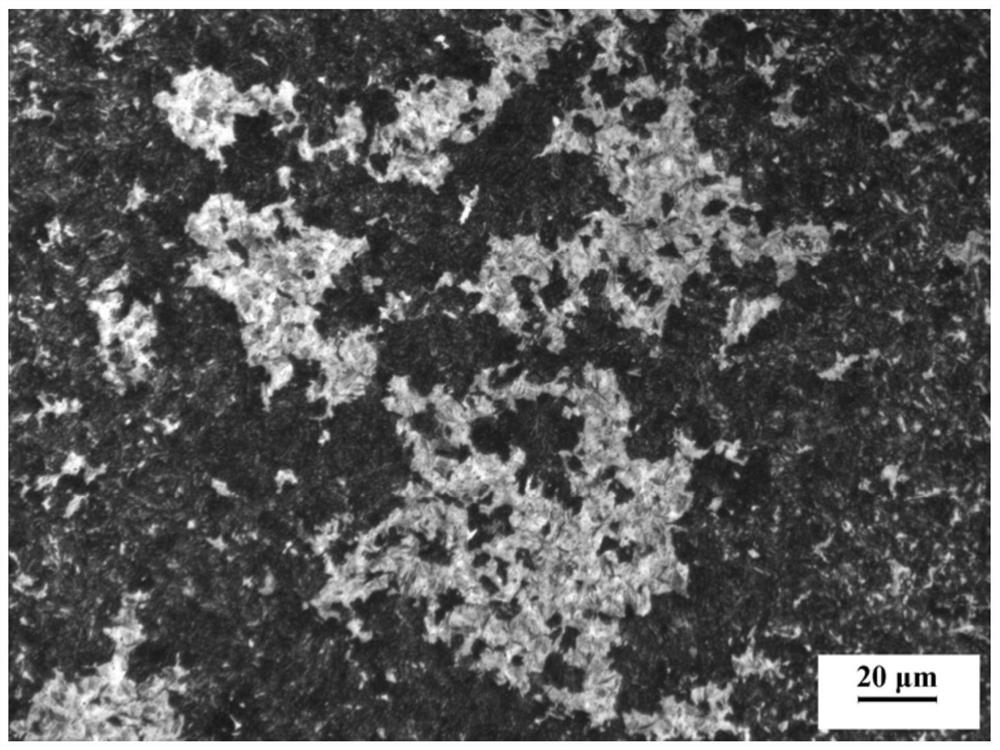

[0099] The metallographic microstructure of the chrome-vanadium series hot-rolled steel wire rod that embodiment 1 makes is as follows: figure 1 with figure 2 As shown, the metallographic microstructure of the chrome-vanadium series hot-rolled steel wire rod prepared in Comparative Example 1 is as follows image 3 shown. Table 8 shows the microstructure of the chrome-vanadium series hot-rolled steel wire rods prepared in various examples and comparative examples, and table 9 shows the decarburization and inclusion levels of the wire rods.

[0100] Table 8. Microstructure of wire rod

[0101] Microstructure Austenite grain size grade center segregation level Example 1 S+P+Small and uniform F 11.5 A1.0 Example 2 S+P+Small and uniform F 11.5 A1.0 Example 3 S+P+Small and uniform F 11.5 A1.5 Example 4 S+P+Small and uniform F 11.5 A1.0 Example 5 S+P+Small and uniform F 11.5 A1.5 Example 6 S+P+Small and uniform F ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com