Super-hydrophobic coating with self-cleaning and organic pollutant degradation functions and preparation method of super-hydrophobic coating

A technology for super-hydrophobic coatings and organic pollutants, applied in coatings and other directions, can solve the problems of skin, eye irritation, corrosive ammonia water, complicated preparation process, etc., and achieve high surface hydroxyl content, high safety performance, microporous many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of superhydrophobic coatings:

[0036] Take 50mL of ethanol, add 10g of hydrophobic silicon dioxide powder and 1.0g of silicone acrylic acid, stir and ultrasonically disperse for 5min until the mixture is uniform, and obtain solution A;

[0037] Take another 50mL of absolute ethanol, add 3g of nano-titanium dioxide and 0.1g of dispersant, stir evenly to obtain solution B;

[0038] Add solution B dropwise to solution A at a rate of 0.5 mL / min, and continue stirring for 2 hours after the dropwise addition to form a milky white liquid.

[0039] The milky white liquid was left to stand for 24 hours, and then dried in an oven at 50-60°C for 12 hours to obtain a dried gel;

[0040] The dried gel was pulverized with a mortar, placed in a muffle furnace and calcined for 2 hours to obtain the superhydrophobic coating of Example 1.

Embodiment 2

[0042] Take 50mL of ethanol, add 10g of hydrophobic silicon dioxide powder and 1.5g of n-butyl ester, stir and ultrasonically disperse for 8 minutes until the mixture is uniform, and obtain solution A;

[0043] Take another 60mL of absolute ethanol, add 3g of nano-titanium dioxide and 0.3g of dispersant, stir evenly to obtain solution B;

[0044] Add solution B dropwise to solution A at a rate of 0.5 mL / min, and continue stirring for 2 hours after the dropwise addition to form a milky white liquid.

[0045] The milky white liquid was left to stand for 24 hours, and then dried in an oven at 50-60°C for 12 hours to obtain a dried gel;

[0046] The dried gel was pulverized with a mortar, placed in a muffle furnace and calcined for 2 hours to obtain the superhydrophobic coating of Example 2.

Embodiment 3

[0048] Take 48mL of ethanol, add 10g of hydrophobic silica powder and 1.2g of dodecyl alcohol ester, stir and ultrasonically disperse for 8 minutes until the mixture is uniform, and obtain solution A;

[0049] Take another 60mL of absolute ethanol, add 4g of nano-titanium dioxide and 0.2g of dispersant, stir evenly to obtain solution B;

[0050] Add solution B dropwise to solution A at a rate of 0.5 mL / min, and continue stirring for 2 hours after the dropwise addition to form a milky white liquid.

[0051] The milky white liquid was left to stand for 24 hours, and then dried in an oven at 50-60°C for 12 hours to obtain a dried gel;

[0052] The dried gel was pulverized with a mortar, placed in a muffle furnace and calcined for 2 hours to obtain the superhydrophobic coating of Example 3.

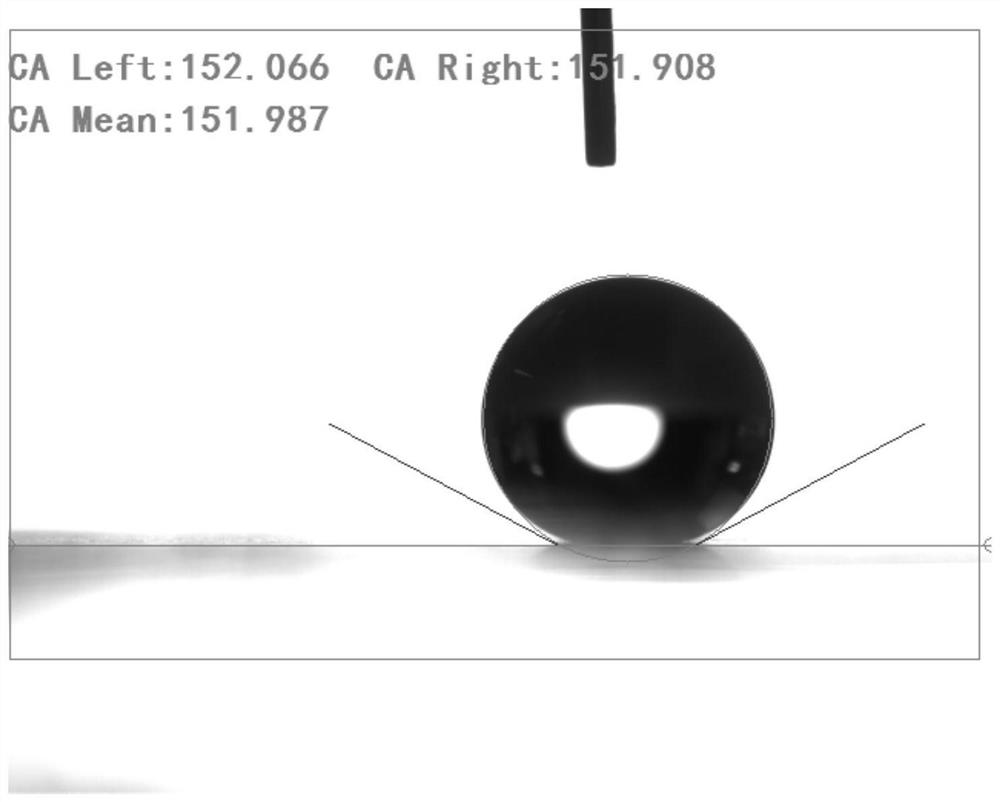

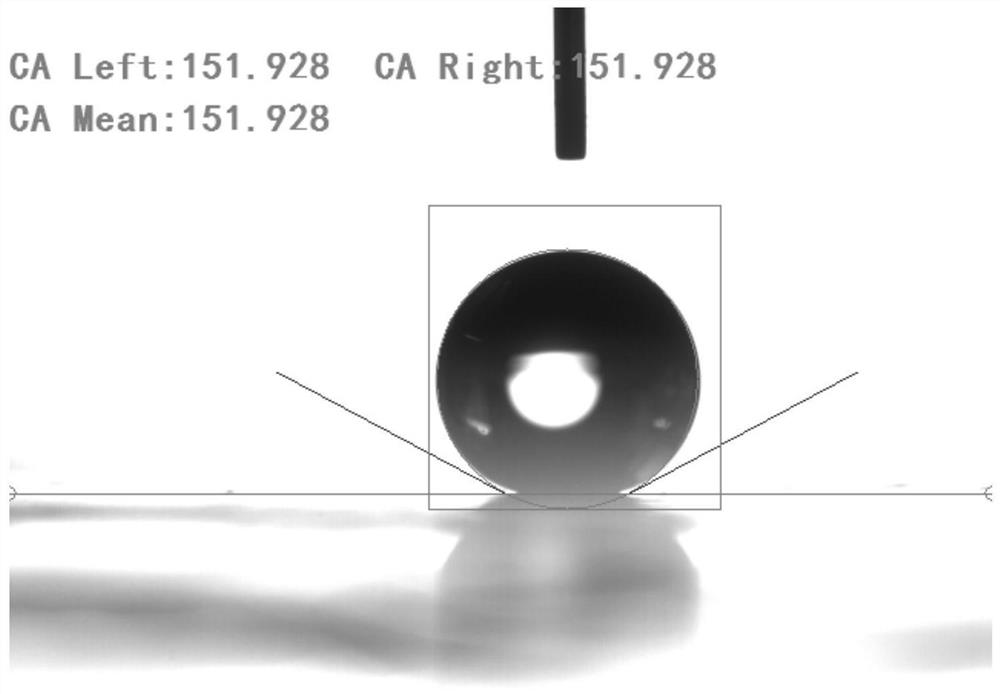

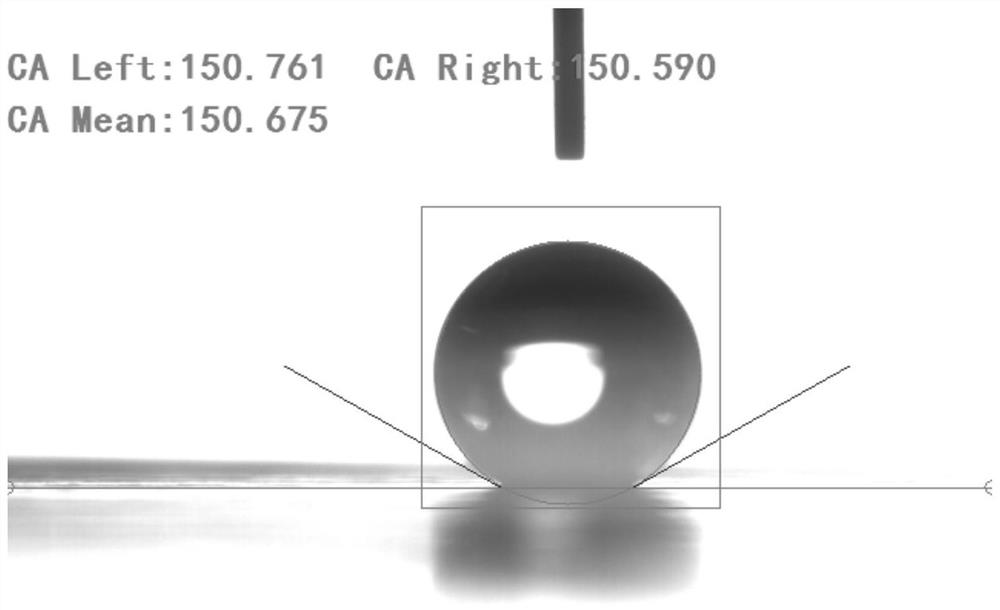

[0053] The hydrophobic performance of the transparent superhydrophobic material prepared in the embodiment of the present invention was characterized by using an integral inclined contact an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com