Fiber-wound reinforced graphite heating tube structure and preparation method thereof

A heating tube and graphite technology, which is applied in the direction of electric heating devices, heating element materials, ohmic resistance heating, etc., can solve the problems of long densification process, prolong service life, poor oxidation resistance, etc., and achieve excellent flexural strength and tensile strength performance, good thermal shock resistance, and good flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

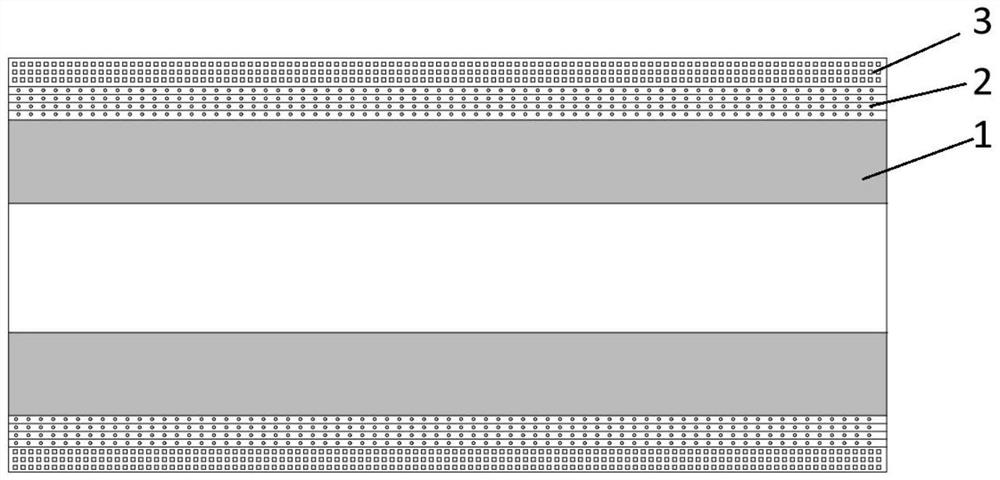

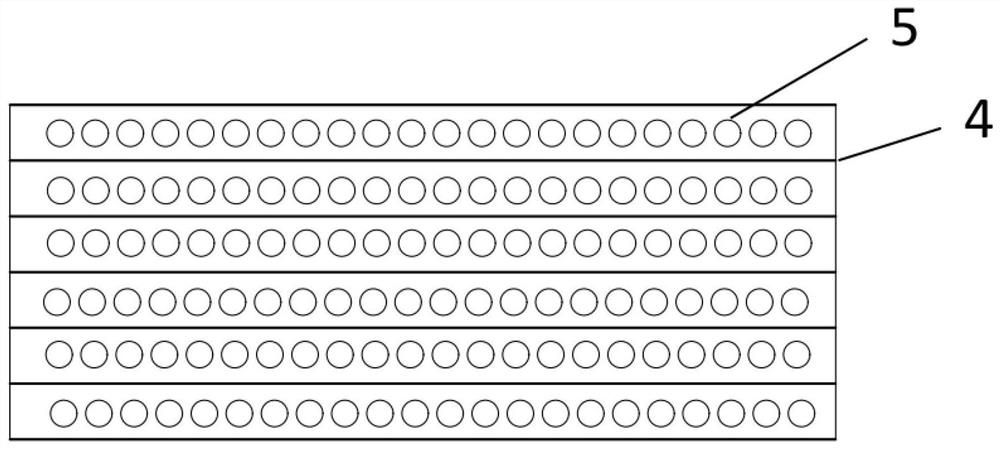

[0040] The fiber-wound reinforced graphite heating tube structure of this embodiment includes a graphite heating tube, a dry yarn winding reinforcement layer coated on the outer surface of the graphite heating tube, and a silicon carbide anti-oxidation coating coated on the surface of the dry yarn winding reinforcement layer, such as figure 2 As shown, the dry yarn winding reinforcement layer is composed of carbon fiber and pyrolytic carbon, and the pyrolytic carbon is evenly distributed in the carbon fiber, as shown in image 3 shown.

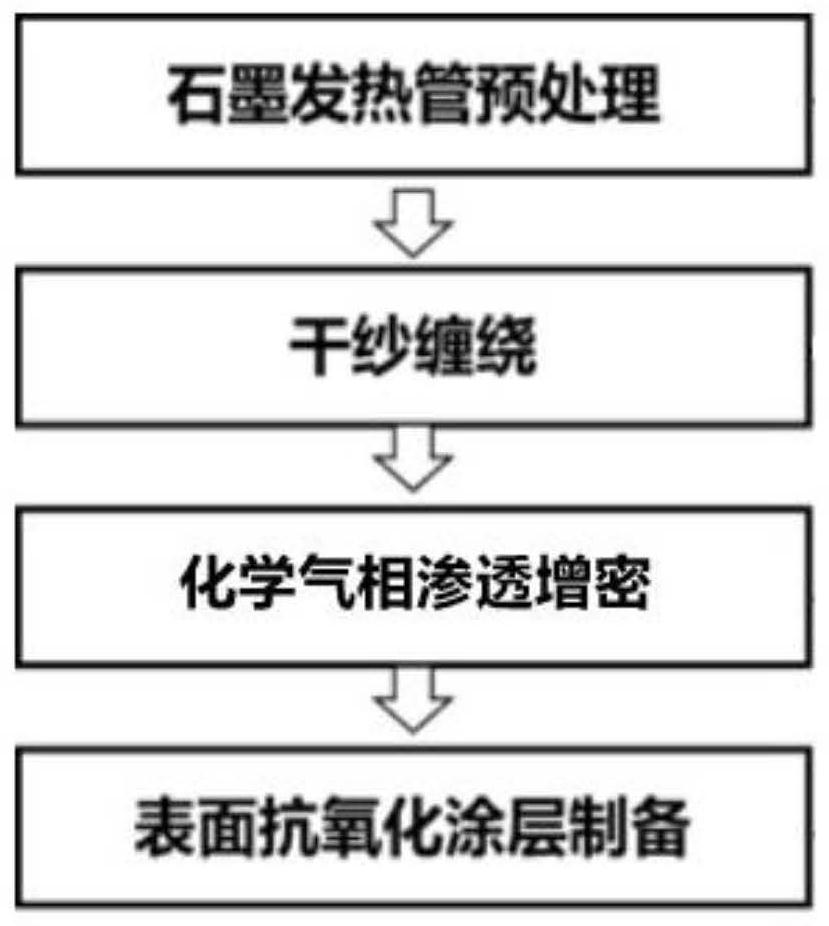

[0041] The preparation method of the fiber winding reinforced graphite heating tube structure of this embodiment comprises the following steps:

[0042] Step 1. Pretreatment of graphite heating tube: place the graphite heating tube in a vacuum impregnation furnace and fill it with epoxy resin solution, vacuum impregnate the graphite heating tube at a temperature of 60°C and a pressure of 800Pa, and then use nitrogen gas in the Pressurize and...

Embodiment 2

[0048] The fiber-wound reinforced graphite heating tube structure of this embodiment includes a graphite heating tube, a dry yarn winding reinforcement layer coated on the outer surface of the graphite heating tube, and a silicon carbide anti-oxidation coating coated on the surface of the dry yarn winding reinforcement layer, such as figure 2 As shown, the dry yarn winding reinforcement layer is composed of carbon fiber and pyrolytic carbon, and the pyrolytic carbon is distributed in the carbon fiber along the direction from the inner surface to the outer surface according to the volume content gradient, as shown in Figure 4 As shown, the incremental range of the volume content is 9% / mm.

[0049] The preparation method of the fiber winding reinforced graphite heating tube structure of this embodiment comprises the following steps:

[0050] Step 1. Pretreatment of the graphite heating tube: place the graphite heating tube in a vacuum impregnation furnace and fill it with epox...

Embodiment 3

[0056] The fiber-wound reinforced graphite heating tube structure of this embodiment includes a graphite heating tube, a dry yarn winding reinforcement layer coated on the outer surface of the graphite heating tube, and a silicon carbide anti-oxidation coating coated on the surface of the dry yarn winding reinforcement layer, such as figure 2 As shown, the dry yarn winding reinforcement layer is composed of carbon fiber and pyrolytic carbon, and the pyrolytic carbon is distributed in the carbon fiber along the direction from the inner surface to the outer surface according to the volume content gradient, as shown in Figure 4 As shown, the incremental range of the volume content is 3% / mm.

[0057] The preparation method of the fiber winding reinforced graphite heating tube structure of this embodiment comprises the following steps:

[0058] Step 1. Pretreatment of graphite heating tube: place the graphite heating tube in a vacuum impregnation furnace and fill it with epoxy re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hoop tensile strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com